Water area tunnel formwork supporting structure and integral sliding structure of internal formwork support

A technology of integral sliding and internal mold, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of high labor intensity of brackets, large force of internal mold brackets, slow installation and disassembly speed, etc. The effect of labor intensity, force balance and low cost of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

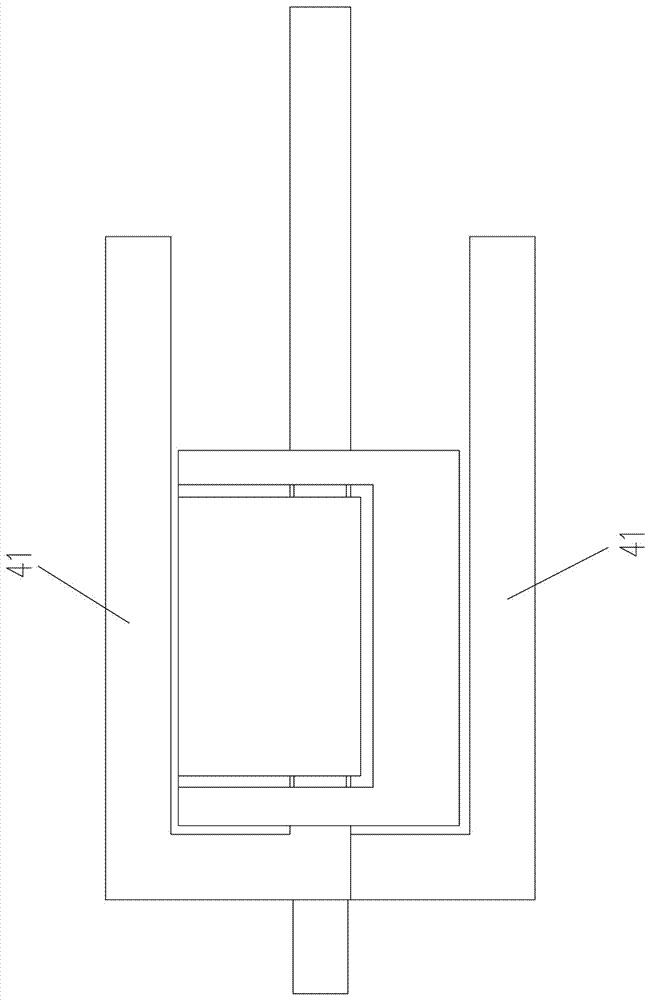

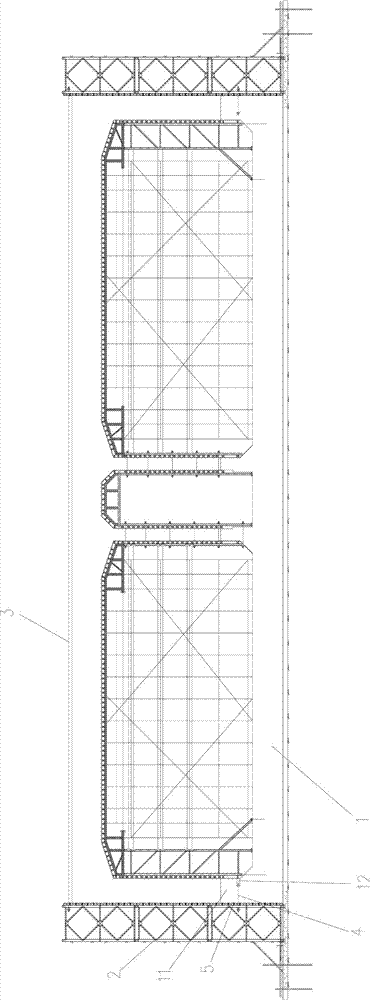

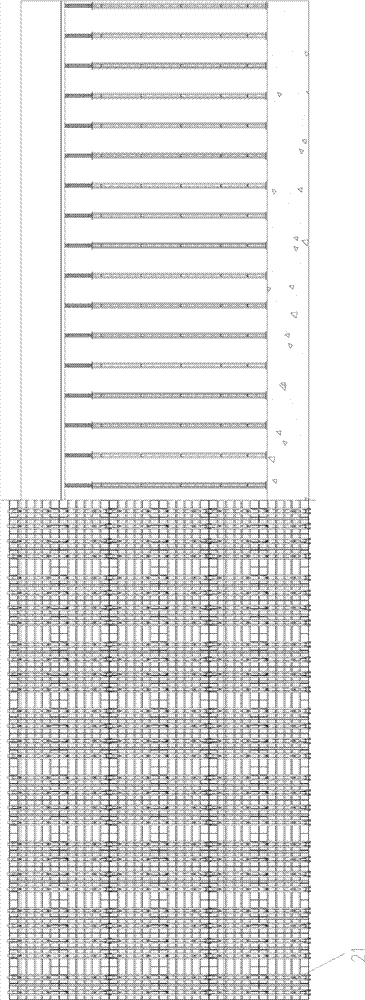

[0049] A formwork structure of a water tunnel without cross-tie pull screws, including a base plate 1 of concrete poured in advance, an outer mold support built on both sides of the base plate, and an inner mold support built on the base plate for forming an inner mold 1. The outer formwork 5 and the inner formwork fixed on the inner side of the outer formwork support and the outer side of the inner formwork support respectively; Also connected between the base plates is a connecting steel bar 4 with one end pre-embedded in the base plate and the other end protruding from the base plate to connect with the outer mold support.

[0050] The outer mold support is a Bailey truss 2, and the paired tension steel bars and connecting steel bars are finish-rolled rebars.

[0051] The above reinforcement structure method is beneficial to improve the integrity and durability of the concrete structure of the water tunnel without increasing the construction difficulty and relatively saving...

Embodiment 2

[0076] The difference from the above-mentioned embodiment is that the height raised by the jack in the step 4 is about 8 cm from the ground.

Embodiment 3

[0078] The difference from the above-mentioned embodiment is that the height raised by the jack in the step 4 is about 12 cm from the ground.

[0079] The overall sliding technology of the inner mold steel pipe support. This technology effectively shortens the time required to build the internal mold support, speeds up the construction progress, saves project costs, and improves the labor intensity of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com