Metal roof secondary waterproof structure and construction method

A secondary waterproofing, metal roofing technology, applied in the direction of roofing, roof covering, building structure, etc., can solve the problems of not exerting secondary waterproofing, increasing project cost, economic waste, etc., to avoid water accumulation or leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

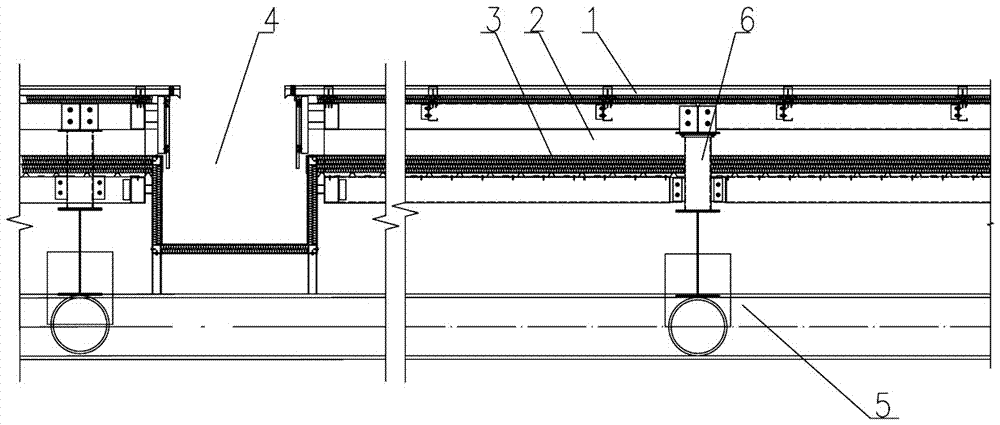

[0059] Such as Figure 1-9 As shown, a secondary waterproof structure of a metal roof includes a roof layer 1, a cavity layer 2, a secondary waterproof layer 3, a gutter 4, a main steel structure 5, and a column purlin support 6. The cavity layer 2 Located between the roof layer 1 and the secondary waterproof layer 3; the column purlin support 6 is supported on the main steel structure 5 for supporting the roof layer 1 and the secondary waterproof layer 3;

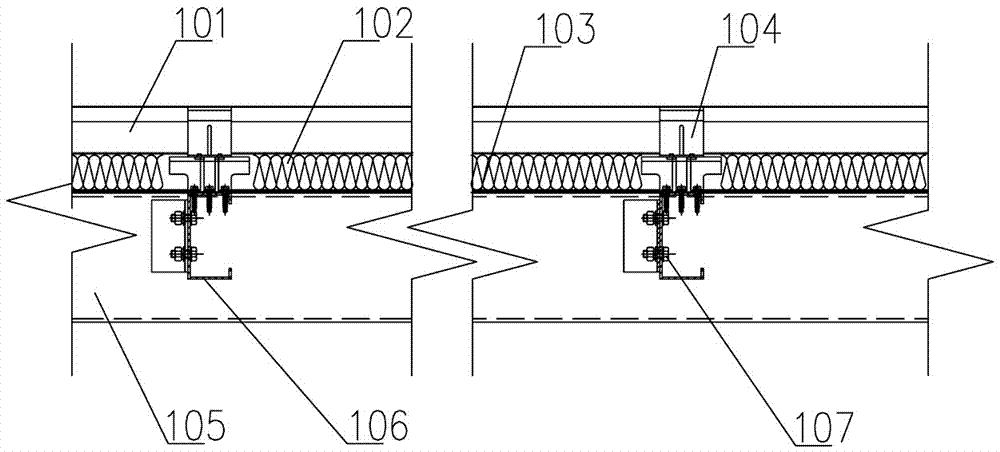

[0060] The roof layer 1 is composed of a metal roof panel 101, a noise reduction layer 102, a steel wire mesh 103, a high-strength aluminum alloy T-shaped support 104, an upper main purlin 105, an upper purlin 106, and fixing bolts 107;

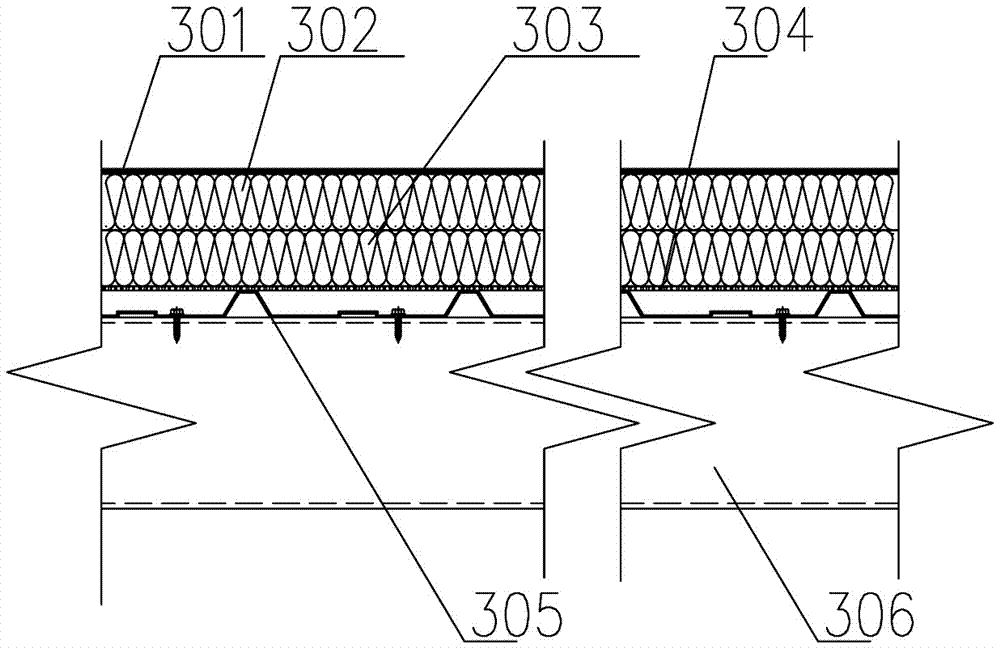

[0061] The secondary waterproof layer 3 is composed of a waterproof coiled material 301, an insulating layer 302, a sound-absorbing layer 303, a vapor barrier layer 304, a perforated aluminum plate 305, a lower purlin 306, and self-tapping screws 307;

[0062] The gutter 4 is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com