Self-pumping hydrodynamic pressure fingertip sealing device

A technology of fingertip sealing and hydrodynamic pressure, which is applied to engine components, machines/engines, and leakage prevention, and can solve problems such as high leakage rate, poor adaptability to rotor precession, and large wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The implementation of the present technology will be described in detail below in conjunction with the drawings and examples.

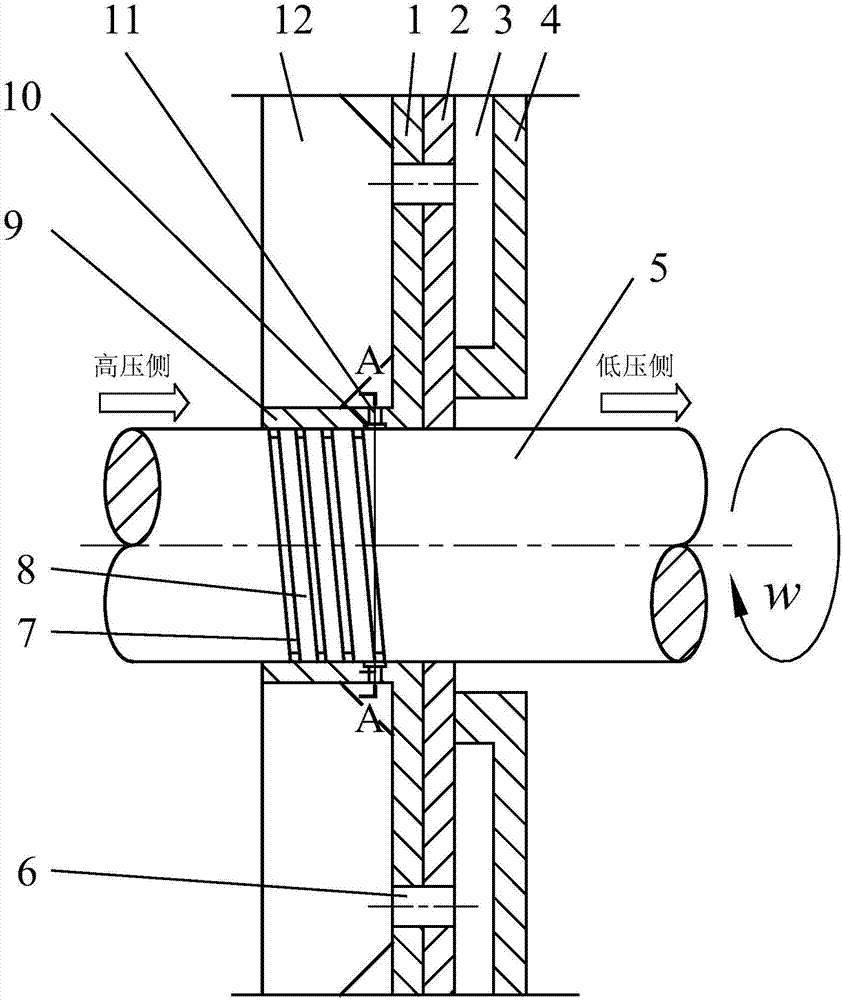

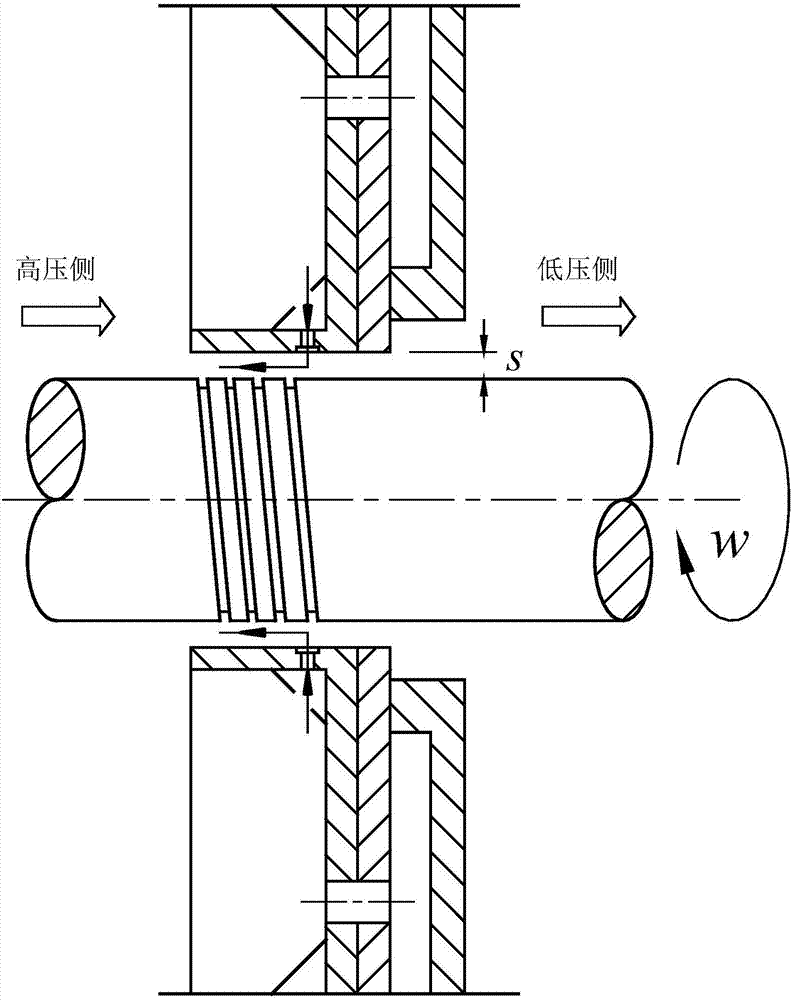

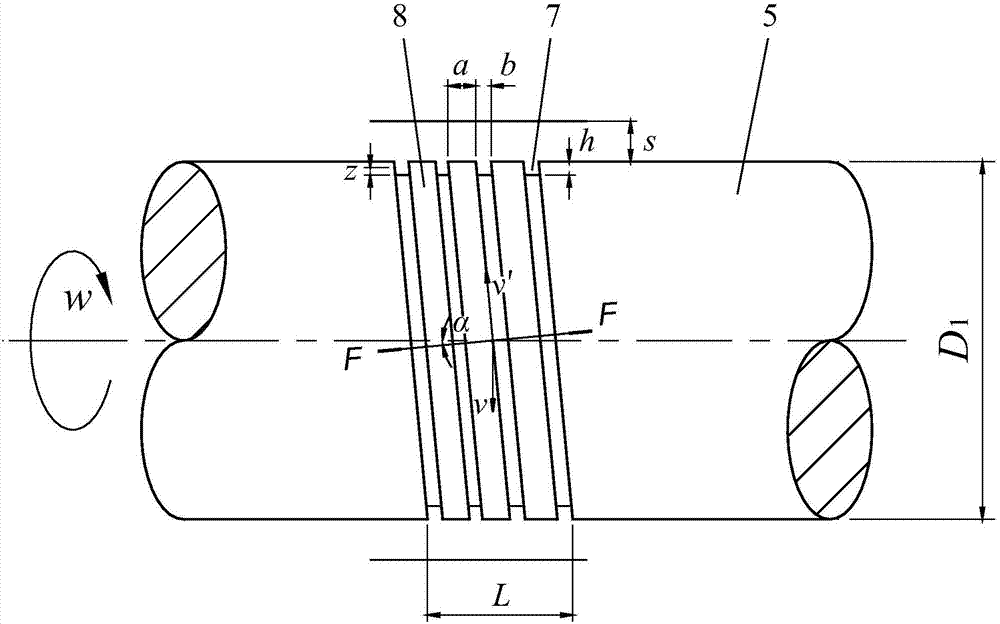

[0094] refer to figure 1 , a self-pumping fluid dynamic pressure fingertip seal device, which is composed of a tailgate 4, a low-pressure fingertip seal 2, a high-pressure fingertip beam 1 with a fingertip shoe 9 and a rotor 5, and a high-pressure fingertip shoe with a fingertip shoe 9 The fingertip beam 1, the low-voltage fingertip seal 2, and the tailgate 4 are sequentially stacked from high pressure to low pressure and connected together by rivets, and are covered on the rotor 5. The fingertip boot 9 of the high-voltage fingertip beam 1 is provided with a A drainage hole 11 with a diameter of d and an inner ring groove 10 with a width of t, and a spiral groove 7 is processed on the surface of the rotor 5 .

[0095] The drainage hole 11 is opened on the fingertip shoe 9 , close to the high-voltage fingertip beam 1 in the axial direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com