Multipoint direct injection head structure for low-pollution combustion chamber of gas turbine

A gas turbine and combustion chamber technology, which is applied in the directions of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of low-polluting combustion of gas turbines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment is a multi-point direct injection head structure used in a low-pollution combustion chamber of a gas turbine.

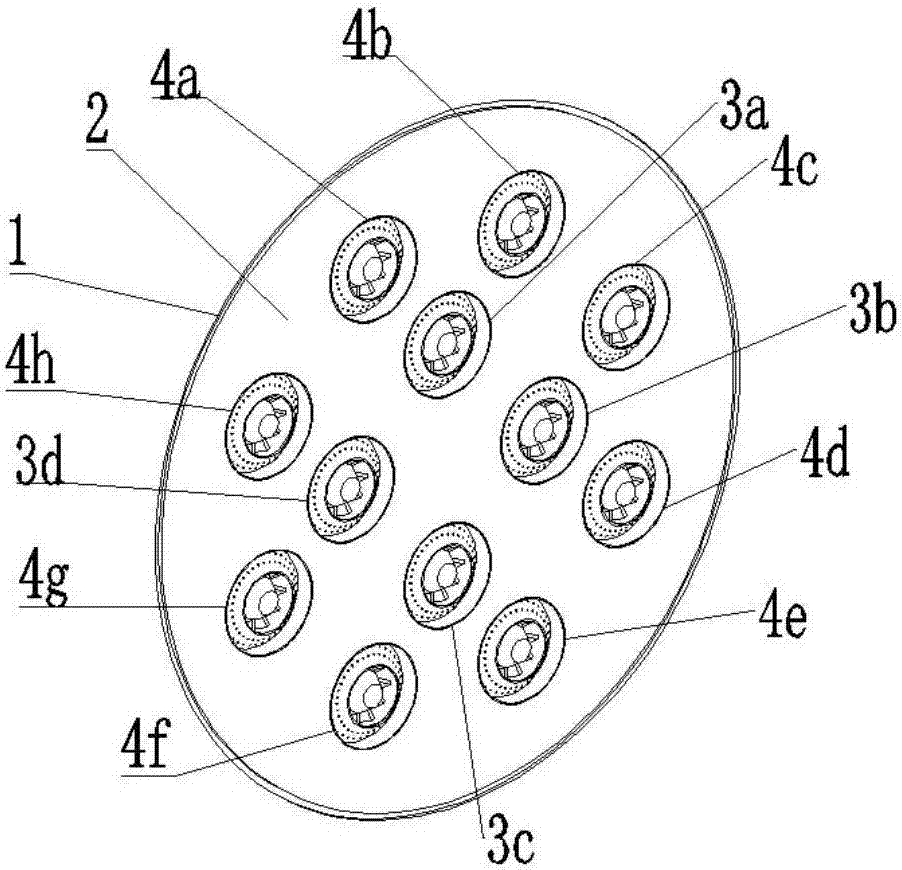

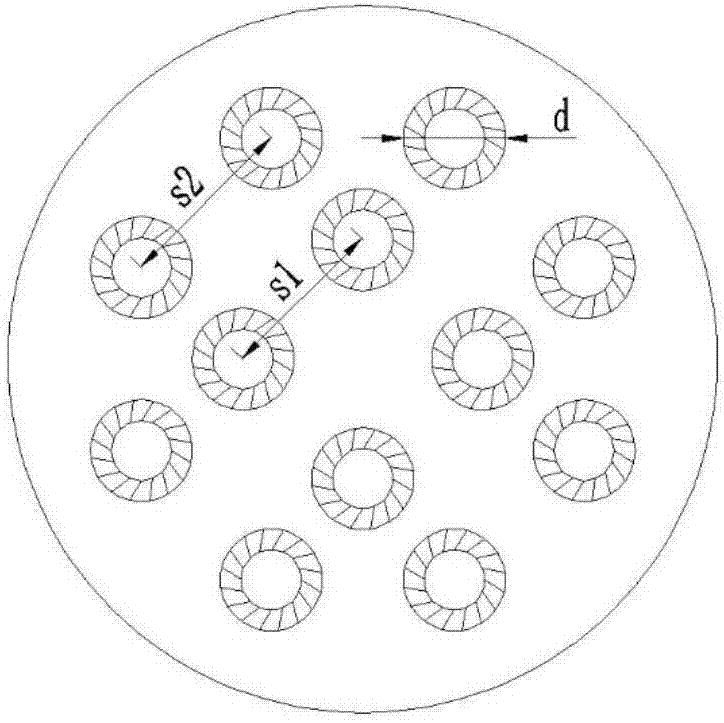

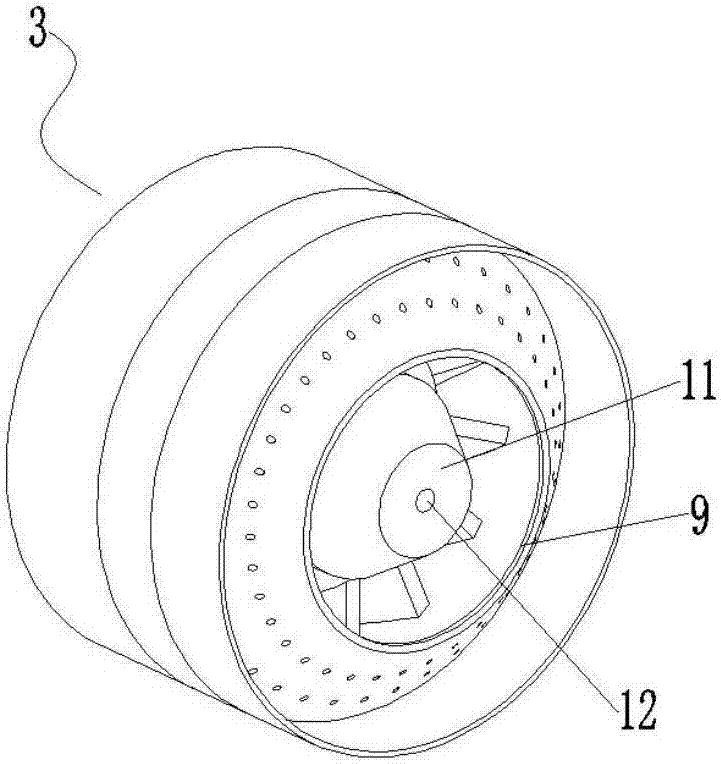

[0027] Such as Figure 1 ~ Figure 4 , this embodiment is used for the multi-point direct injection head structure of the low-pollution combustion chamber of the gas turbine, which consists of the combustion chamber head 1, the combustion chamber head flange 2, the four secondary combustion stage swirl nozzle molds 3, and the eight main combustion stages Swirl nozzle mold 4, air inlet 5, swirl channel 6, annular swirl air straight channel 7, annular swirl air convergence channel 8, swirl air outlet 9, fuel inlet 10, nozzle 11, nozzle outlet 12; Wherein, secondary combustion stage swirl nozzle mold 3 comprises swirl nozzle mold 3a, swirl nozzle mold 3b, swirl nozzle mold 3c, swirl nozzle mold 3d; main combustion stage swirl nozzle mold 4 comprises swirl nozzle mold 4a, Swirl nozzle die 4b, swirl nozzle die 4c, swirl nozzle die 4d, swirl nozzle d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com