Hot-blast recuperative furnace of biomass generating system

A biomass power generation and hot air heat exchange technology, which is used in household furnaces/stoves, solid heating fuels, lighting and heating equipment, etc., can solve problems such as insufficient flame stability, insufficient biomass combustion efficiency, and affecting heat exchange efficiency. , to achieve the effect of strengthening the thermal insulation effect, avoiding high temperature erosion, and stabilizing the central flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

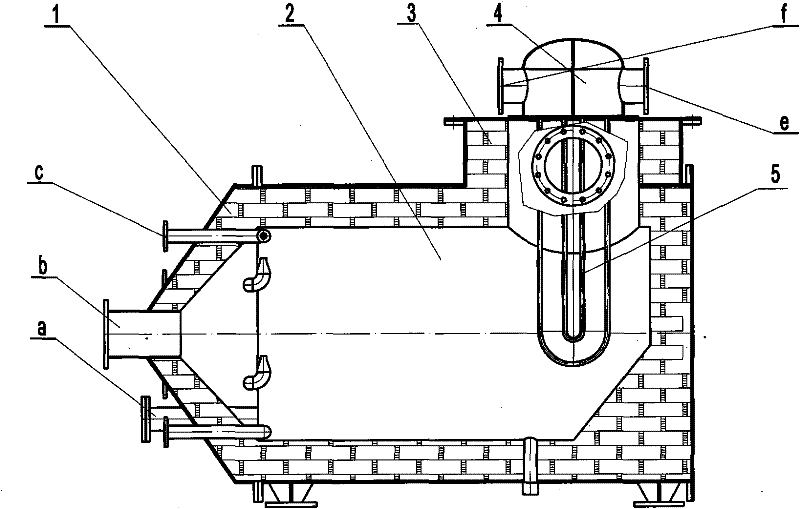

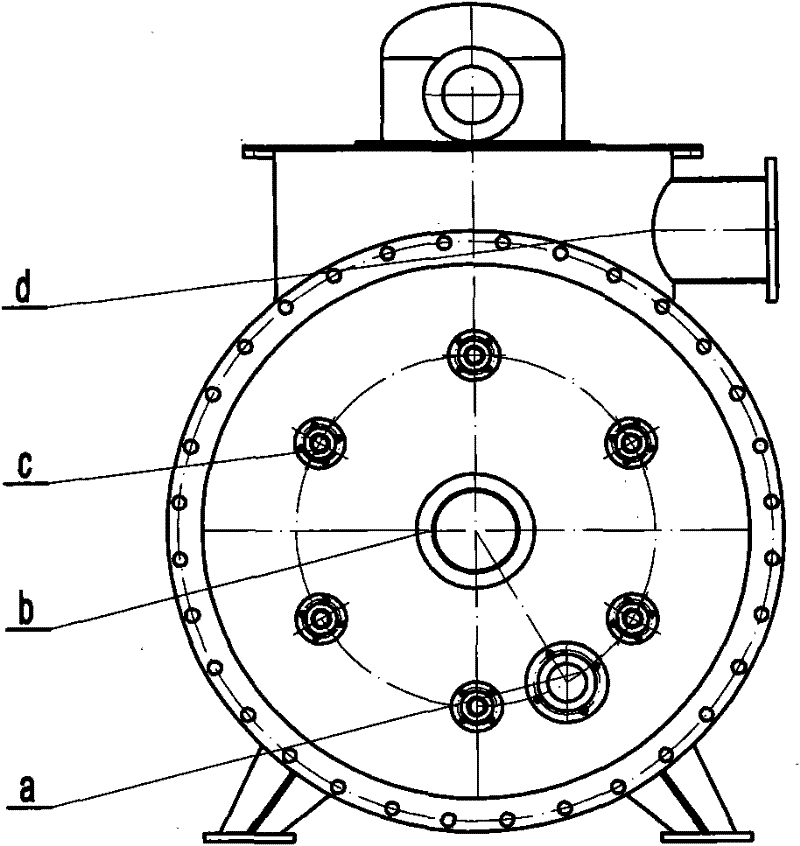

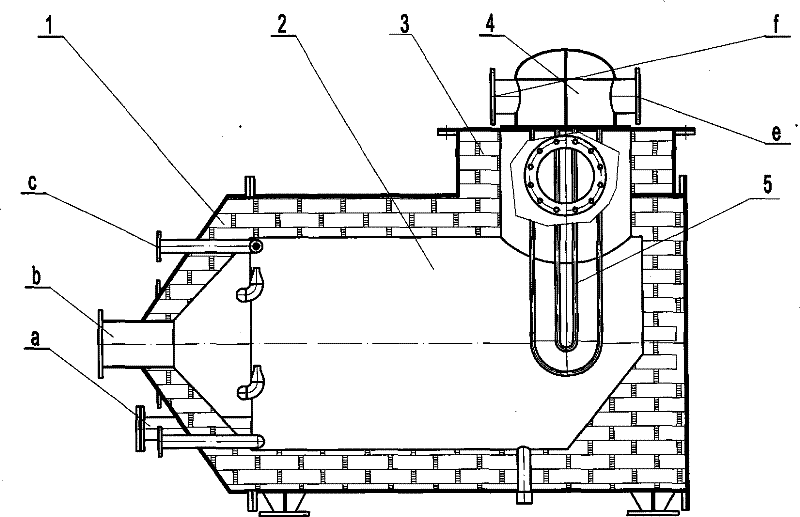

[0012] The hot air heat exchange furnace of the biomass power generation system in this embodiment is as follows: figure 1 As shown, a cylindrical kettle body 2 with an insulating wall 1 is placed horizontally, and the center of one end is provided with a combustion port b through a conical section gradually expanding inward, and a chimney section 3 with a horizontal hot air outlet d extends upward from the other end. The chimney section is inserted with a heat exchanger 4 extending into the cylindrical still body from top to bottom. The heat exchange section 5 of the heat exchanger 4 is composed of a U-shaped heat exchange tube group, and the two upper ports communicate with the heat exchange medium inlet e and the heat exchange medium outlet f exposed outside the chimney section 3 respectively. A group of six air distribution pipes c extending into the cylindrical kettle body are distributed around the combustion port b. The outlets at the inner ends of each air distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com