Biomass semi-gasification furnace and manufacturing method thereof

A semi-gasification and biomass technology, applied in the field of crop waste treatment equipment, can solve the problems of difficult control of gas supply, affecting gas production, blocking secondary air distribution channels, etc., so as to solve the problem of secondary pollution and prevent The production of tar and the effect of improving the quality of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

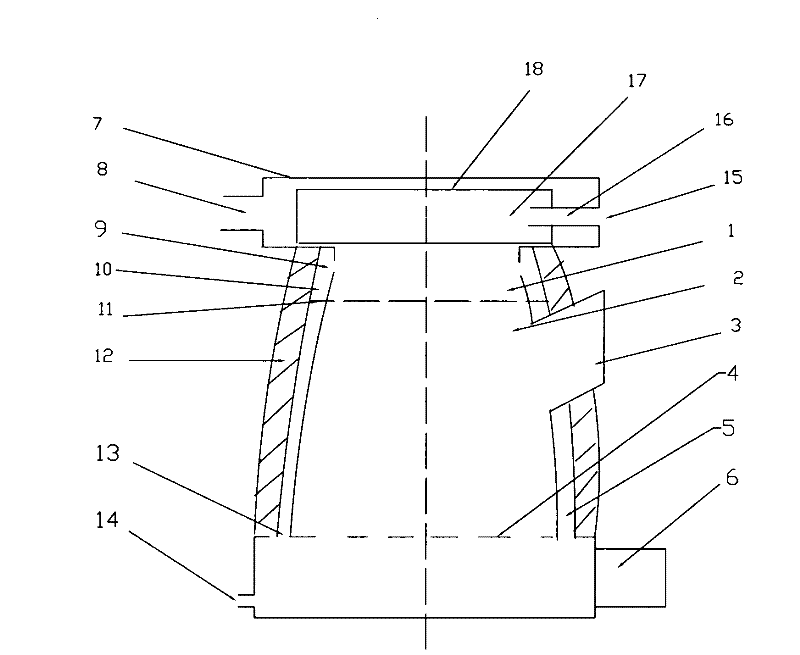

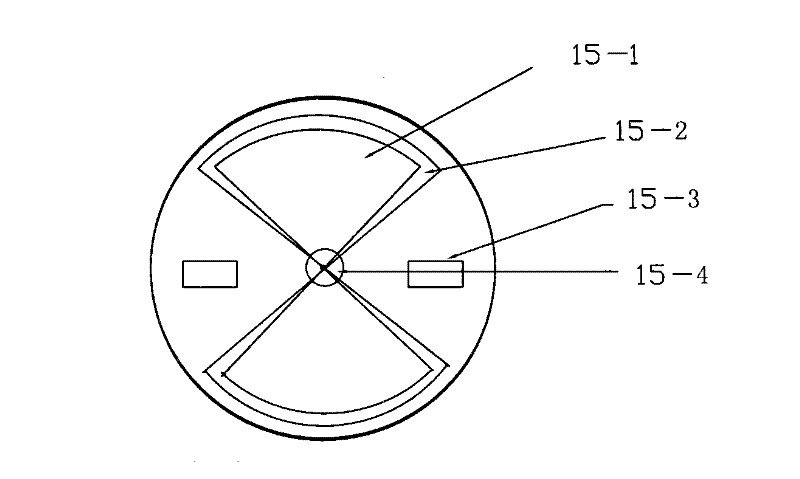

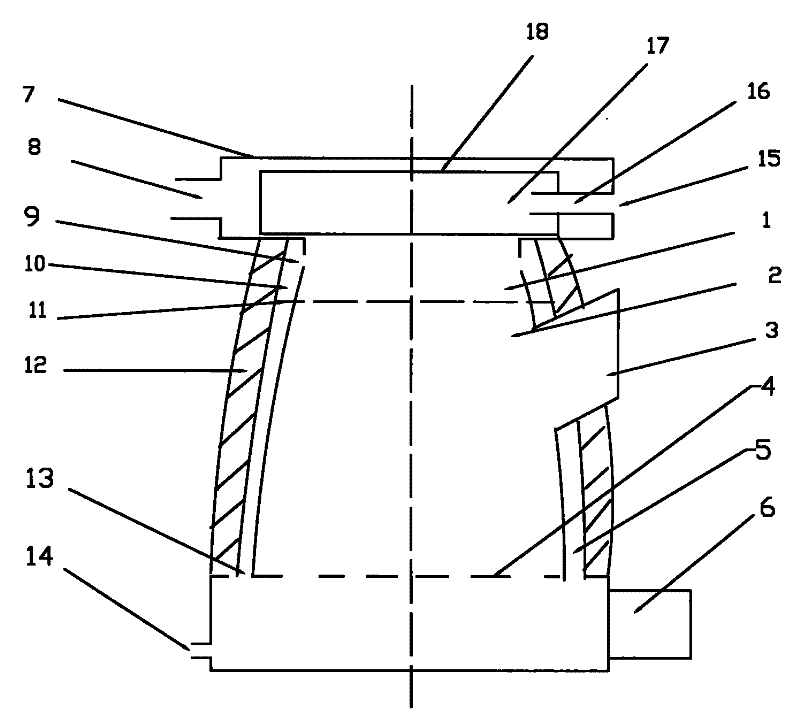

[0034] Such as figure 1 and figure 2 As shown, the biomass semi-gasification furnace of the present invention includes a burner 1, a gasification chamber 2, a feed port 3, a furnace bridge 4, a secondary air inlet channel 5, ash receiving and ventilation chamber 6, a panel surrounding fire cover 7, Flue 8, insulation layer 12 and blower port 14, biomass fuel is added to the inner chamber of the furnace through the feed port 3 to control the overfilling of the feed, avoiding the phenomenon of only smoking but not igniting, and the door can be opened to distribute air when necessary effect. The air required for combustion is supplied through the ash receiving and ventilating chamber 6 and the furnace bridge 4, and the air supply is controlled by adjusting the opening of the ash receiving and ventilating chamber 6, and the combustion of biomass in the furnace is adjusted to reach the state of gasification combustion. At the beginning, it is ignited from the top of the burner 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com