Natural gas hydrate drilled core light hydrocarbon gas content analysis test system and method

A technology for light hydrocarbon gas and hydrate, which is applied in control/regulating systems, measuring devices, analytical materials, etc., to achieve the effects of reduced loss, safe testing process, and high authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

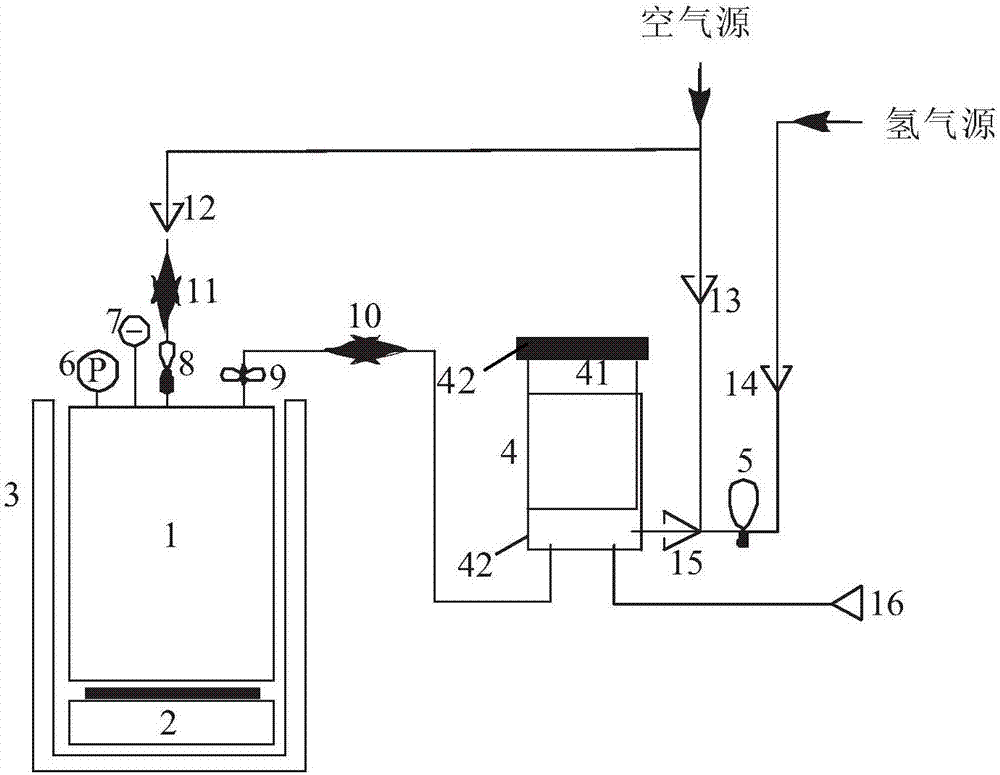

[0068] (1) Sample: synthetic natural gas hydrate sample.

[0069] (2) Working conditions of the instrument: the temperature of the temperature control chamber 3 is 3°C, the flow rate of the first air flow control valve 12 is 10mL / min, the flow rate of the decomposition gas flow control valve 15 is 20mL / min, and the flow rate of the second air flow control valve 13 is 360mL / min, the flow rate of the hydrogen flow control valve 14 is 38mL / min, and the working temperature of the hydrogen flame ionization detector 5 is 250°C.

[0070] (3) System calibration: take 5mL, 25mL, 45mL, 65mL, 85mL, 120mL of methane volume fraction respectively as 37.92% nitrogen-based methane standard gas, inject gas collection chamber 4 from gas inlet 16, and use hydrogen flame ionization detector 5. Perform detection, calculate the signal area per unit volume of methane through data processing, and complete the calibration of the system.

[0071] (4) Sample test:

[0072] 1) Connect the gas path of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com