Magnet-unilateral-distributed magnetic washing separation mechanism of analyzer

A separation mechanism and analyzer technology, applied in the field of medical devices, can solve the problems of poor magnetic bead washing effect, etc., and achieve the effect of saving substrate solution and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

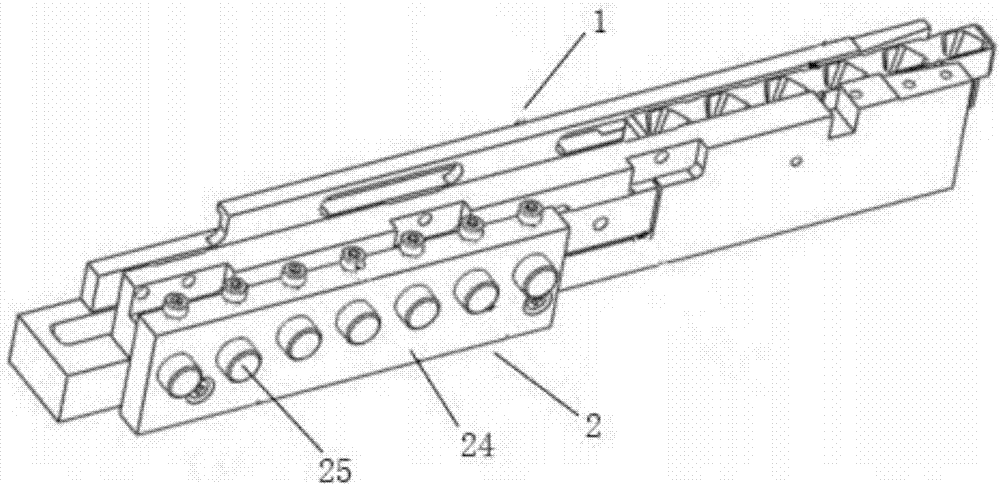

[0024] This embodiment provides a magnetic cleaning and separation mechanism for an analyzer with magnets arranged on one side, such as figure 1 As shown, it includes: a number of magnet groups, located on the same side of the conveyor belt of the cuvette conveying assembly 1 and arranged along the conveying direction of the cuvette conveying assembly 1;

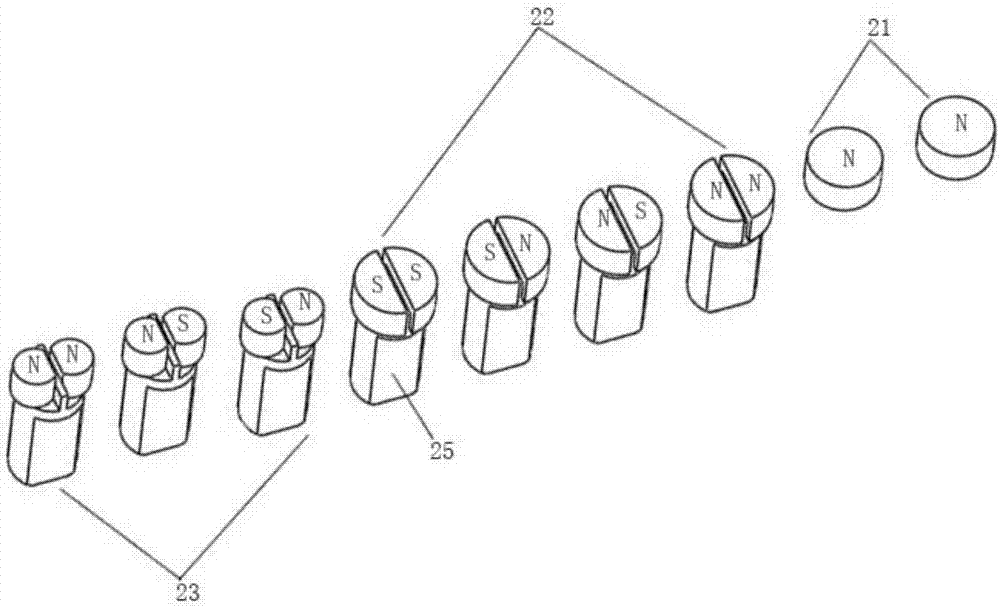

[0025] Such as figure 2 As shown, the magnet group includes a first magnet group 21, a second magnet group 22, and a third magnet group 23 arranged in sequence; the first magnet group 21 includes more than two magnets, and each magnet is close to the pole on the side of the reaction cup. The second magnet group 22 includes more than four magnetic components, each magnetic component includes two magnets arranged in parallel, the two magnets of the two magnet components at the front and rear ends have the same magnetic pole direction, and the remaining magnetic components have two magnets The magnetic pole directions are differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com