A Steam Generator Feedwater Temperature Control Simulation System

A technology of steam generator and control simulation, which is applied in the direction of using electric mode for temperature control, auxiliary controller with auxiliary heating device, etc., which can solve the problem of large changes in the feed water flow rate of the steam generator and the difficulty of controlling the feed water temperature of the steam generator Increase and other problems, to achieve the effect of improving energy utilization, rapid adjustment, and eliminating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

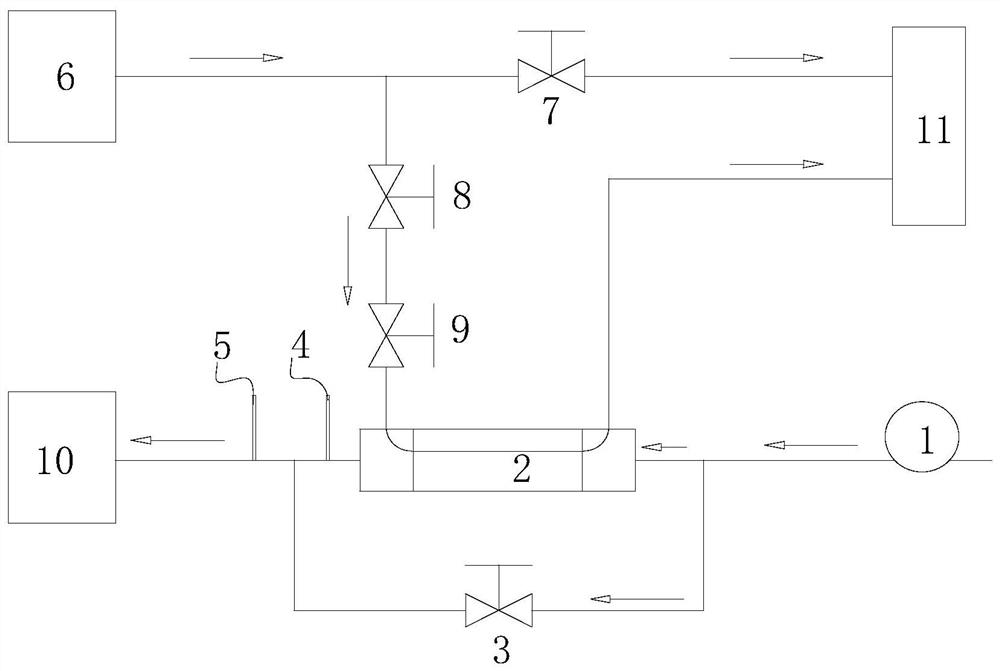

[0018] Such as figure 1 As shown, the present invention is a steam generator feed water temperature control simulation system, the main feed water pipe of the steam generator is connected with the main feed water pump 1 and the secondary side inlet 10 of the steam generator, and is divided into two parallel branches in the middle, one flow After passing through the regenerator 2, the fluid is heated by the steam on the other primary side of the regenerator 2, and then merges with the fluid of another branch, that is, the feedwater bypass, and flows to the secondary side inlet 10 of the steam generator; the feedwater bypass is installed on the feedwater bypass The flow regulating valve 3 is used to adjust the flow rate of the feed water bypass, and the heat exchange temperature measuring device 4 is installed on the outlet pipe of the regenerator 2 to measure the temperature of the feed water coming out of the regenerator 2. The inlet temperature measuring device 5 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com