A preparation method of yttrium iron garnet/bismuth heterogeneous thin film with giant magneto-optical effect

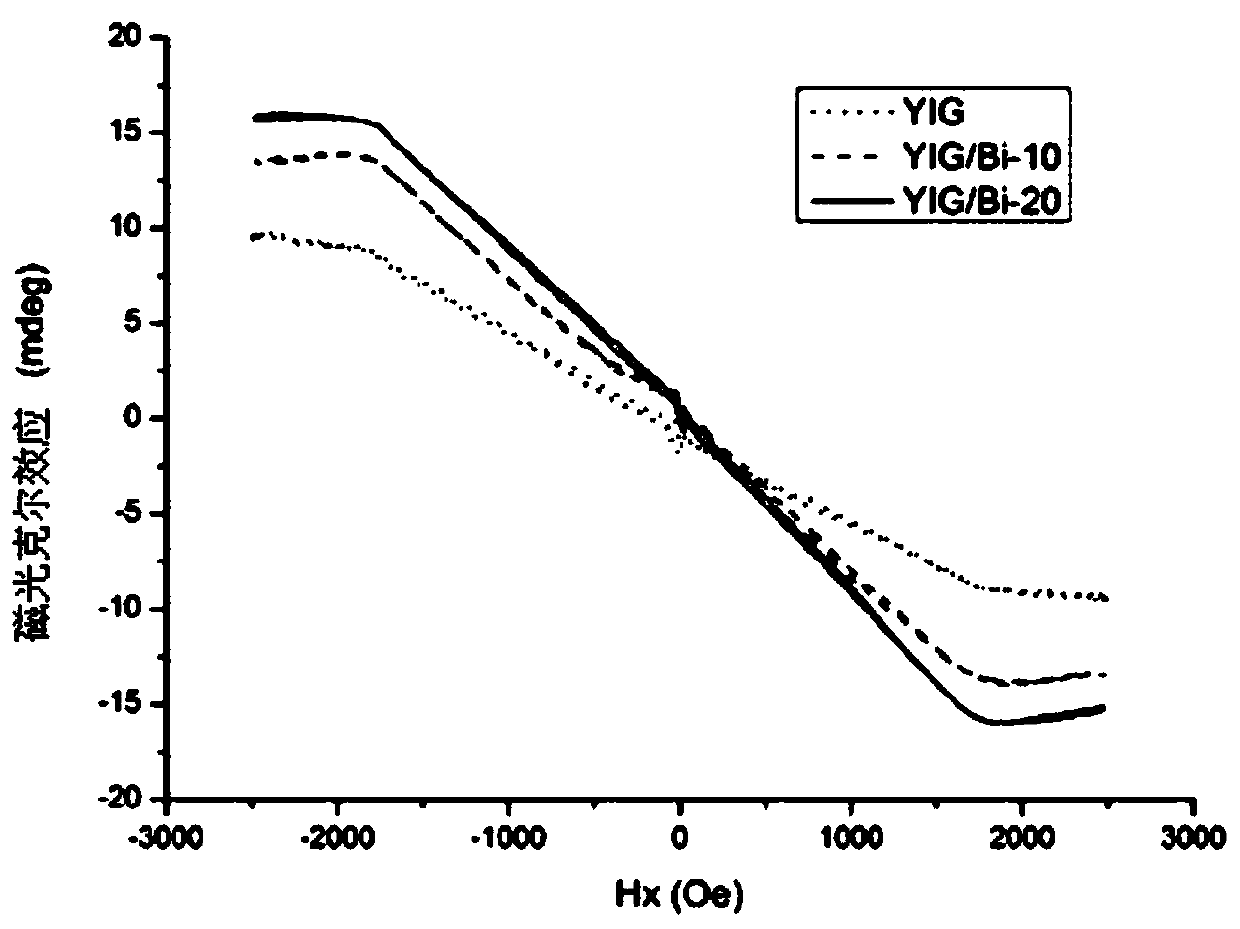

A technology of yttrium iron garnet and optical effect, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of weak magneto-optic effect, difficulty, lattice mismatch, etc., and achieve the increase of magneto-optic Kerr angle The effect of large size and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

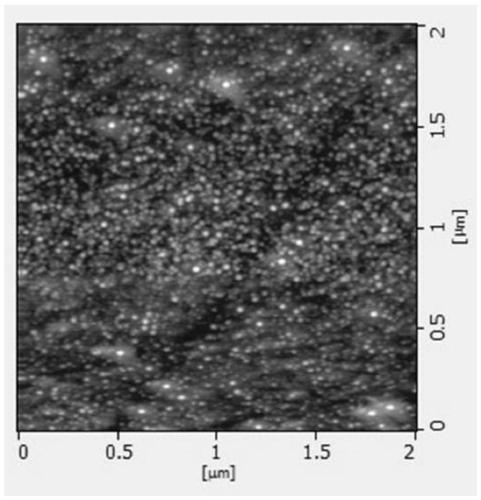

[0023] Yttrium-iron-garnet / bismuth heterogeneous thin films with giant magneto-optical effect, including high-quality single-crystal yttrium-iron-garnet (YIG) grown on [111]-oriented gadolinium-gallium garnet (GGG) by liquid-phase epitaxy As the substrate, a very thin layer of bismuth is grown on the YIG substrate by molecular beam epitaxy (MBE) technology to obtain the yttrium iron garnet / bismuth heterogeneous thin film.

[0024] The thickness of the yttrium iron garnet substrate is 490nm.

[0025] A giant magneto-optical effect yttrium iron garnet / bismuth heterogeneous thin film structure and a preparation method thereof, comprising the following steps:

[0026] Step 1: Select gadolinium gallium garnet (GGG) with [111] crystal orientation as the substrate, and use high-quality yttrium iron garnet (YIG) grown by liquid phase epitaxy, wash with acetone, alcohol and deionized water, and use nitrogen gas Blow dry to ensure that the YIG surface is dry and clean;

[0027] Step 2...

Embodiment 2

[0033] Yttrium-iron-garnet / bismuth heterogeneous thin films with giant magneto-optical effect, including high-quality single-crystal yttrium-iron-garnet (YIG) grown on [111]-oriented gadolinium-gallium garnet (GGG) by liquid-phase epitaxy As the substrate, a very thin layer of bismuth is grown on the YIG substrate by molecular beam epitaxy (MBE) technology to obtain the yttrium iron garnet / bismuth heterogeneous thin film.

[0034] The thickness of the yttrium iron garnet substrate is 500nm.

[0035] A giant magneto-optical effect yttrium iron garnet / bismuth heterogeneous thin film structure and a preparation method thereof, comprising the following steps:

[0036] Step 1: Select gadolinium gallium garnet (GGG) with [111] crystal orientation as the substrate, and use high-quality yttrium iron garnet (YIG) grown by liquid phase epitaxy, wash with acetone, alcohol and deionized water, and use nitrogen gas Blow dry to ensure that the YIG surface is dry and clean;

[0037] Step 2...

Embodiment 3

[0043] Yttrium-iron-garnet / bismuth heterogeneous thin films with giant magneto-optical effect, including high-quality single-crystal yttrium-iron-garnet (YIG) grown on [111]-oriented gadolinium-gallium garnet (GGG) by liquid-phase epitaxy As the substrate, a very thin layer of bismuth is grown on the YIG substrate by molecular beam epitaxy (MBE) technology to obtain the yttrium iron garnet / bismuth heterogeneous thin film.

[0044] The thickness of the yttrium iron garnet substrate is 470nm.

[0045] A giant magneto-optical effect yttrium iron garnet / bismuth heterogeneous thin film structure and a preparation method thereof, comprising the following steps:

[0046] Step 1: Select gadolinium gallium garnet (GGG) with [111] crystal orientation as the substrate, and use high-quality yttrium iron garnet (YIG) grown by liquid phase epitaxy, wash with acetone, alcohol and deionized water, and use nitrogen gas Blow dry to ensure that the YIG surface is dry and clean;

[0047] Step 2: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com