Installation structure and construction method of restraint-typed concrete beam column

A technology for installing structure and concrete, applied in the direction of building structure, construction, etc., can solve the problems of large construction node load, difficulty in pouring and vibrating concrete, enlarged section steel and steel bar, etc., so as to improve the longitudinal bearing capacity and expand the space. Utilization rate, the effect of reducing component size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

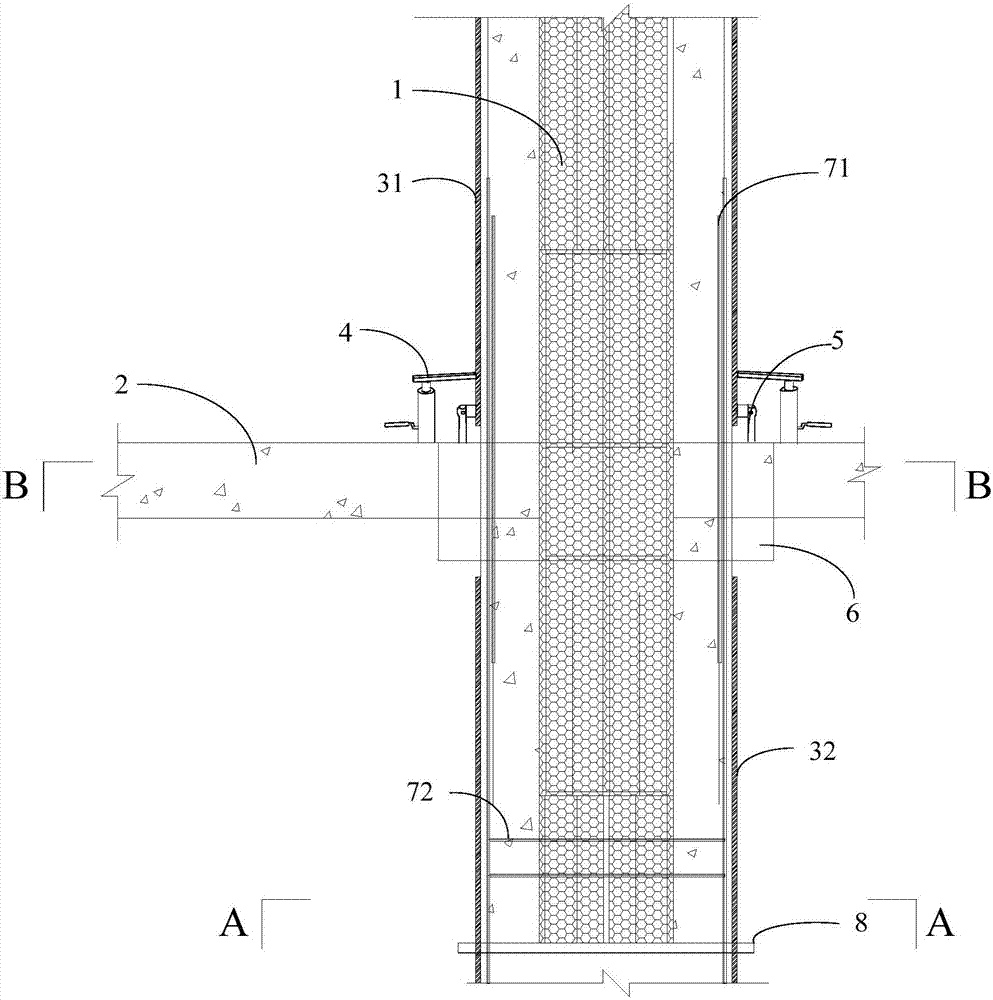

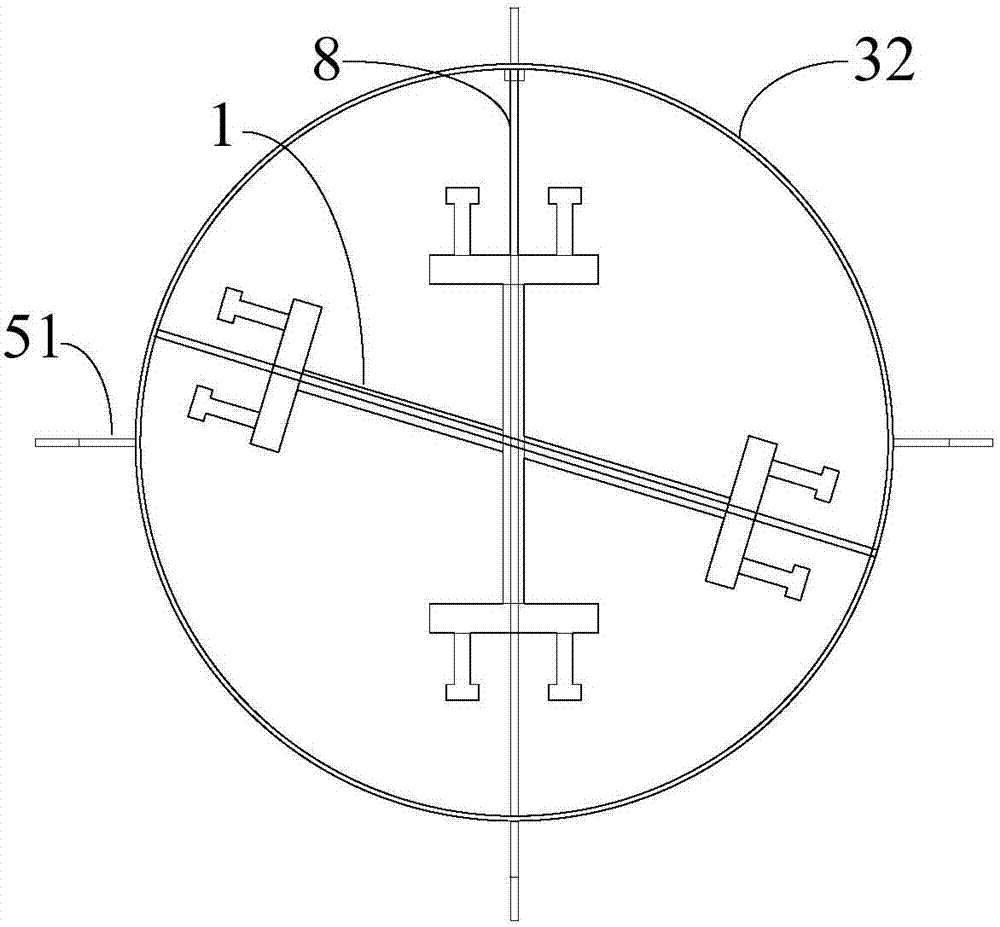

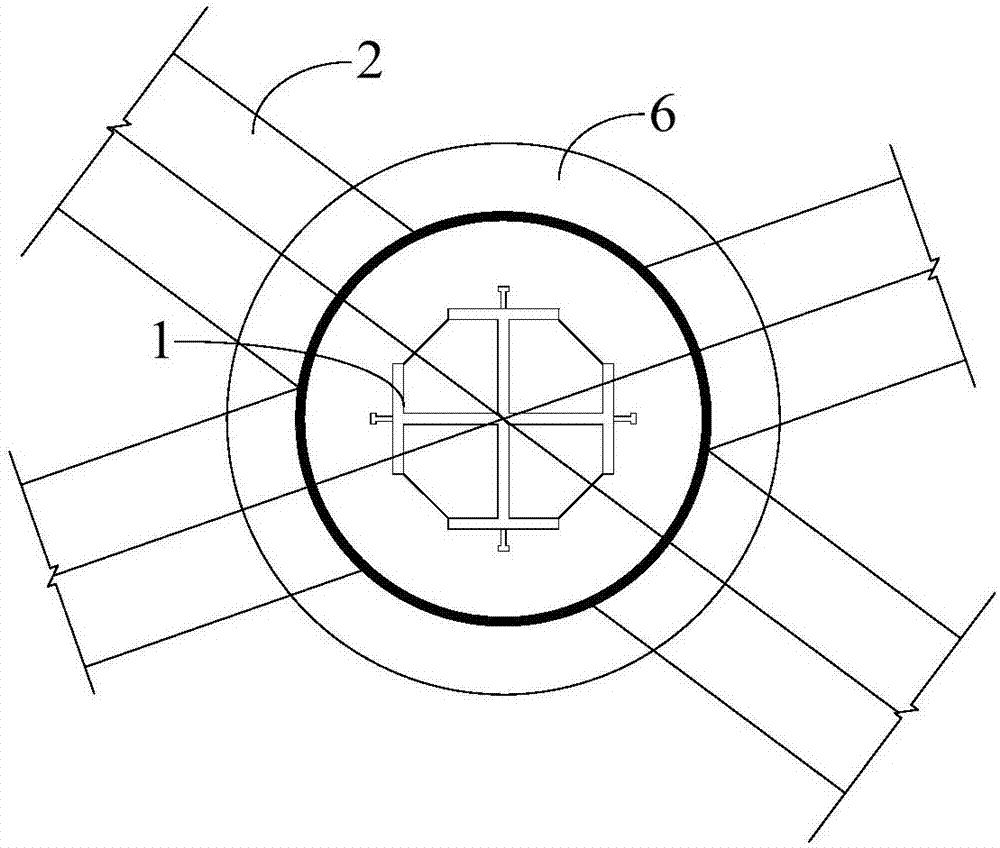

[0034] see figure 1 , figure 2 as well as image 3 The purpose of the present invention is to provide a concrete beam-column installation structure to increase the load and simplify the structure at the joints of the beam-column installation, thereby facilitating concrete pouring and vibration. In order to achieve the above object, the present invention provides a constrained concrete beam column installation structure, including: a prefabricated steel column erected on the foundation structure; a prefabricated steel beam 2 fixed to the prefabricated steel column 1; a constraint Sleeve, the constraint sleeve includes a first cylinder 31 sleeved on the prefabricated steel column 1 above the prefabricated steel beam 2 and a second sleeve sleeved on the prefabricated steel column 1 below the prefabricated steel beam 2 32; and an adjustment support mechanism, including an angle adjustment member 4 for adjusting the angle of the first cylinder body 31 and a reinforcement support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com