Preparation system and method of environment-friendly material for wall

An environmentally friendly material and preparation system technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem of not being able to improve the bearing capacity of the wall, and achieve the effect of simple installation, convenient processing, and increased longitudinal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

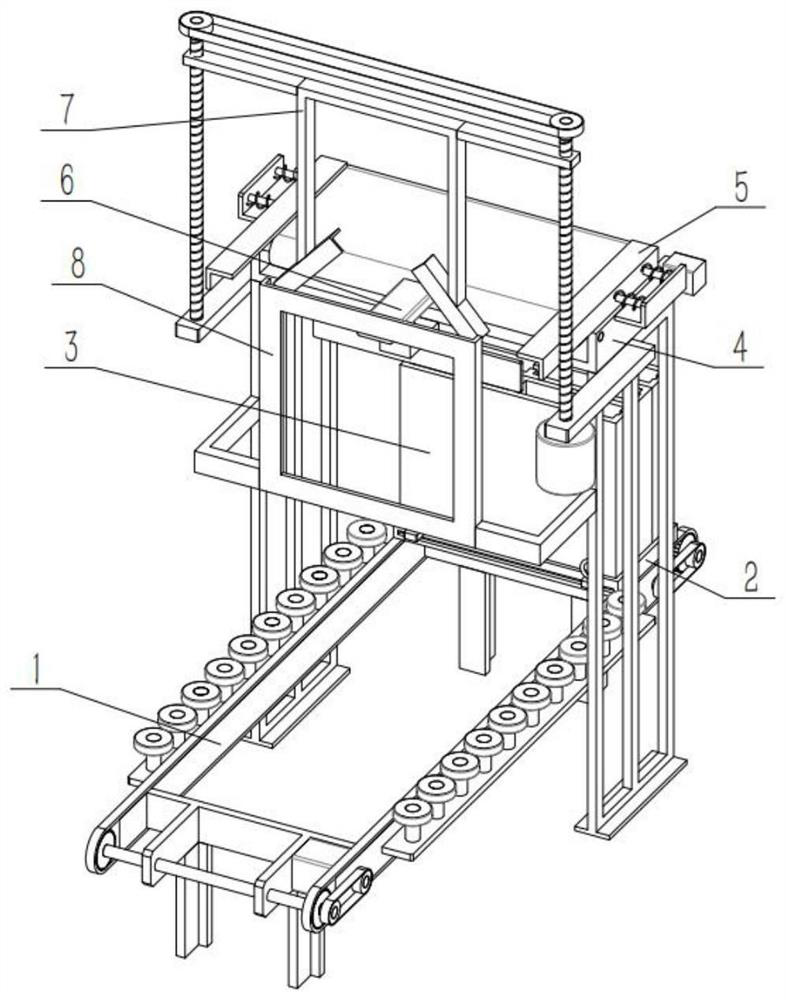

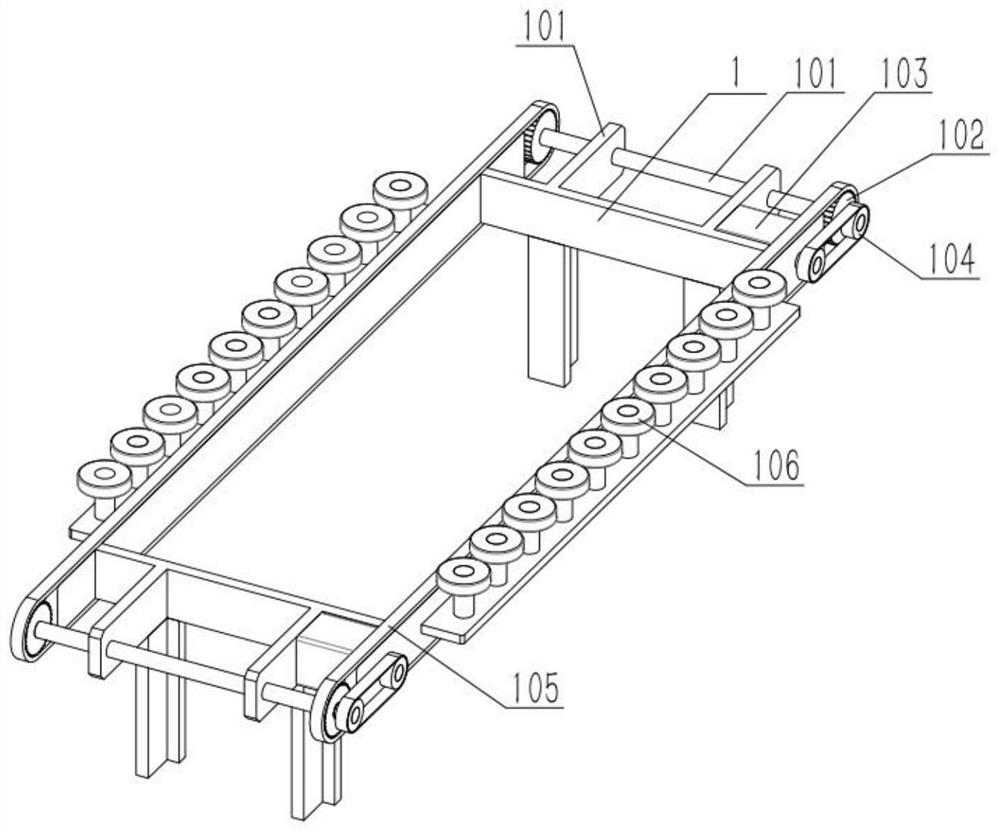

[0036] As shown in the figure, a system for preparing environmentally friendly materials for walls includes a frame I1, a main shaft 101, a sprocket 102, a motor I103, a pulley I104, a transmission chain 105 and a bag seat 2. The front and rear of the frame I1 are two Each end of the main shaft 101 is rotatably connected to a main shaft 101, and the left and right ends of the main shaft 101 are fixedly connected to a sprocket 102, and the two corresponding sprockets 102 are connected through a transmission chain 105, and the inner end surface of the transmission chain 105 can be connected to the upper surface of the frame I1. The end faces are slidingly fitted, and the bag seat 2 can be smoothly transported from front to back through two transmission chains 105;

[0037] The above-mentioned environment-friendly material preparation system for walls also includes an environment-friendly material for walls;

[0038] The environmental protection material for the wall includes a c...

specific Embodiment approach 2

[0040] As shown in the figure, the system for preparing environmentally friendly materials for the wall also includes guide wheels 106, the left and right ends of the upper end of the frame I1 are respectively connected to a row of guide wheels 106, and the left and right ends of the bag seat 2 can be respectively connected to the left and right sides. The guide wheel 106 on the side rolls and fits. The guide wheel 106 makes the bag seat 2 smooth when moving in a straight line.

specific Embodiment approach 3

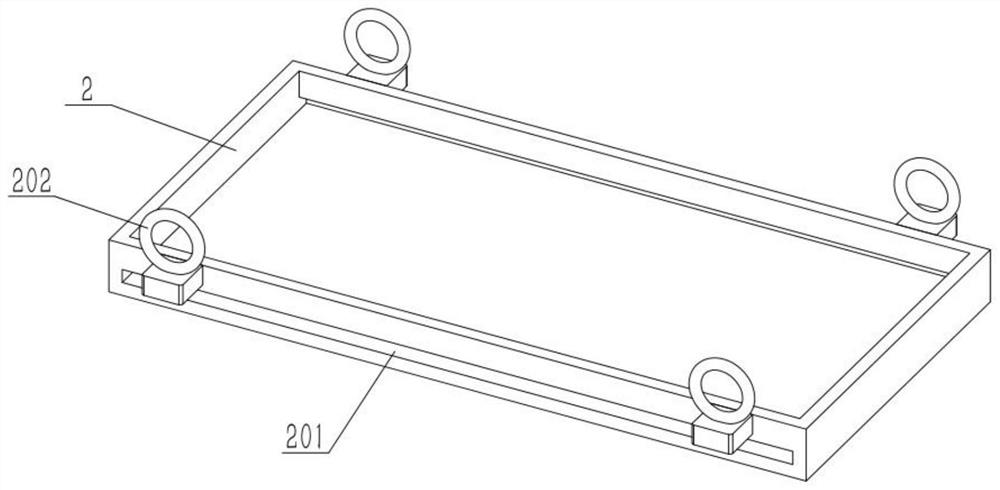

[0042] As shown in the figure, the front and rear ends of the bag seat 2 are respectively provided with a through slot 201 . When pouring material into the concrete wall body 3, the pouring material contacts with the bag seat 2 to easily produce a bonding layer, and through the slot 201, tools such as cutters can be used to pass through the slot 201 to hang up debris.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com