High-rise automatic fire prevention system

An automatic, high-rise technology, applied in fire prevention, fire rescue, war damage prevention, etc., can solve the problems of lagging foreign aid, threatening people's lives and property safety, and achieve the effect of reducing fear, property loss, and invasion probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

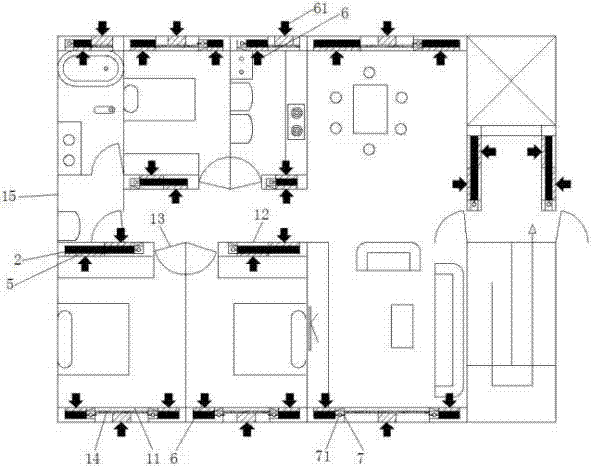

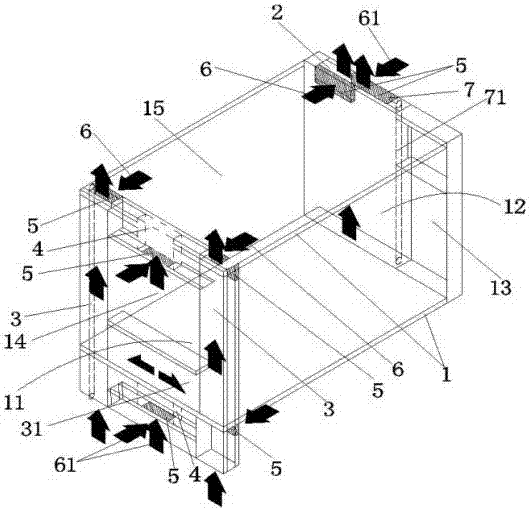

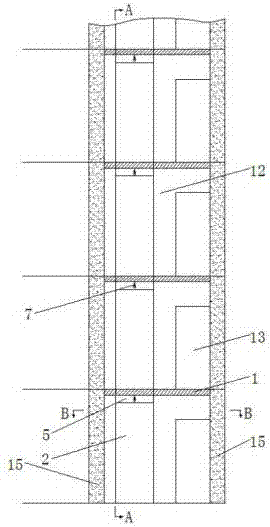

[0037] like Figure 1 to Figure 18 As shown, a kind of high-rise automatic fire prevention system comprises the multi-storey rooms separated by the floor 1 and adjacently distributed up and down, each room is separated by a partition wall 12 and a load-bearing wall 15 to form a plurality of rooms adjacent to each other, each Wherein the opposite side walls of the room are load-bearing walls 15, and the other opposite side walls are respectively a front wall 11 and a partition wall 12, the middle part of the front wall 11 is provided with a window 14, and one side of the partition wall 12 is provided with a window 14. The lower part is provided with a door 13, and the first wall cavity type flue 2 vertically extending up and down is provided on the side of the door 13 in the partition wall 12, and the first wall cavity type flue 2 of a plurality of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com