Scattering device arranged in dryer

A technology for dryers and broken shafts, which is applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problems of limited influence, limited drying strengthening effect, etc., and achieves increased speed, simple structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

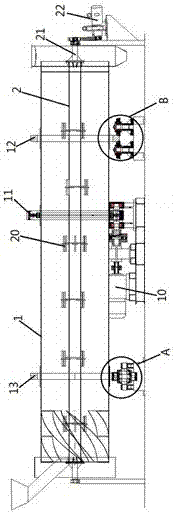

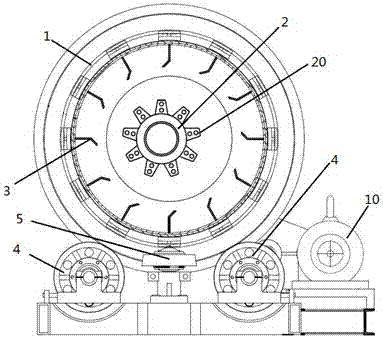

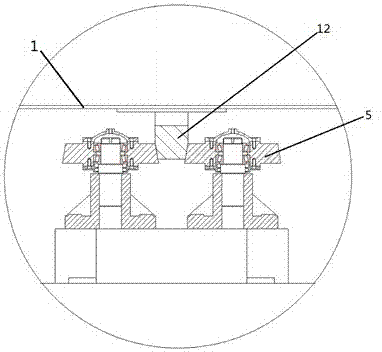

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of the present invention provides an internal breaking device of a dryer, which includes a drum body 1, a drum driving device, a supporting wheel set, a frame, and a breaking shaft 2, and the supporting wheel set is installed on On the frame, the drum body 1 is supported on the support wheel set, the inner wall of the drum body 1 is uniformly provided with lifting plates 3, and the outer wall of the drum body 1 is fixed A running belt and a ring gear 11 are provided. In this embodiment, the ring gear 11 is fixed on the middle part of the drum body 1 by welding, and there are two running belts, that is, the first running belt 12, The second running belt 13, the first running belt 12 is fixedly arranged on the circumferential outer wall of the drum body 1 on the right side of the ring gear 11, and the second running belt 13 is fixedly arranged on the drum body on the left side of the ring gear 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com