Deviation rectification centring automatic control system based on digitized processing

An automatic control system and processor technology, applied in the general control system, control/adjustment system, control using feedback, etc., can solve the problems of low reliability, lack of human-computer interaction, poor automation, etc., to improve reliability and advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

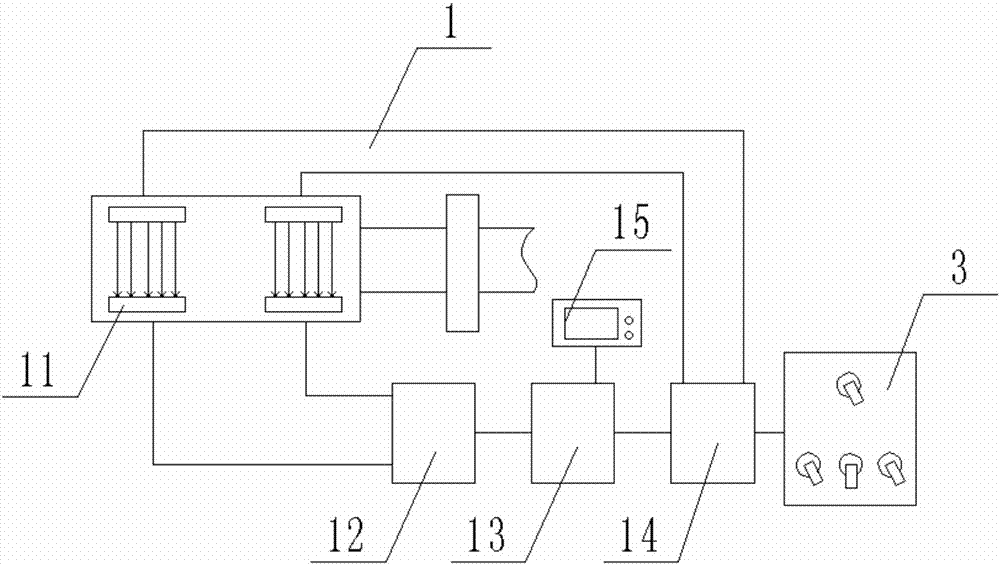

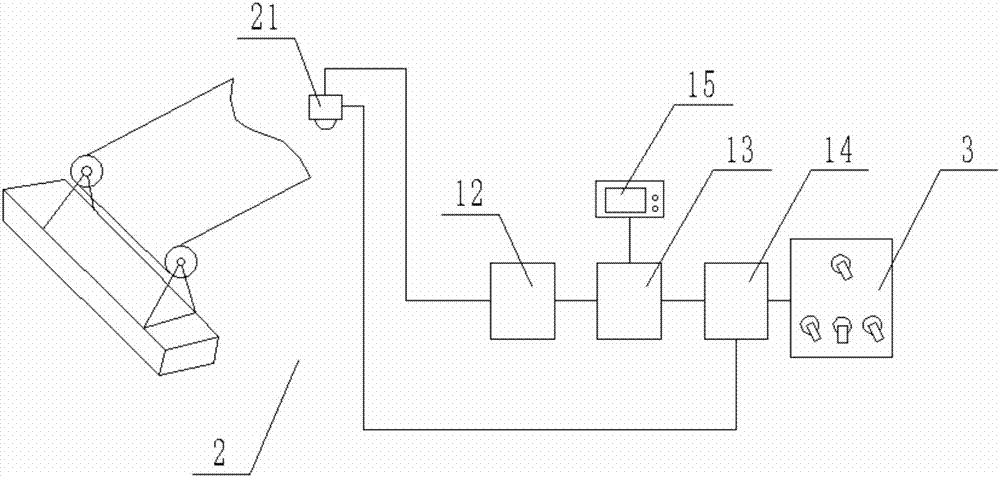

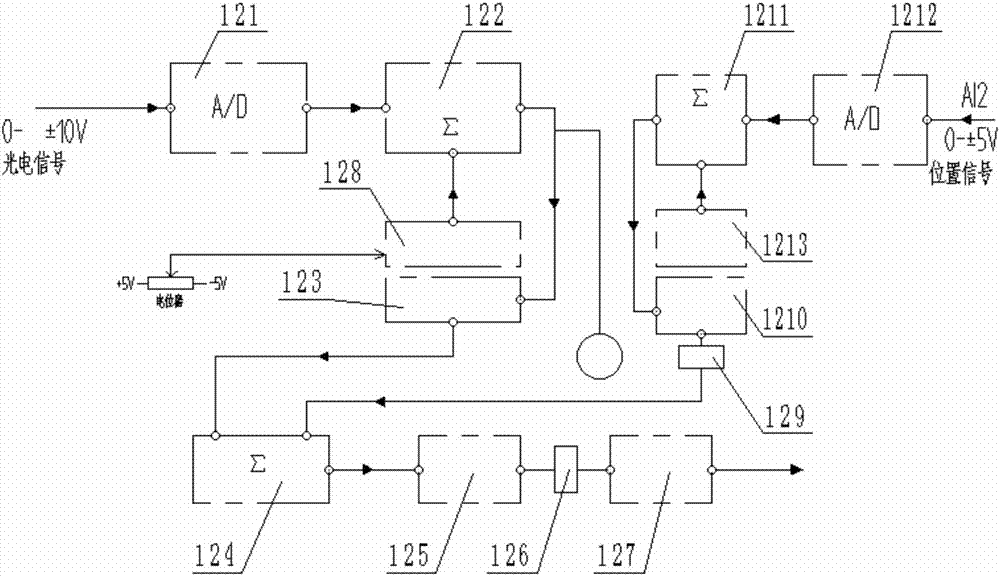

[0017] see Figure 1-2 As shown, an automatic centering control system based on digital processing includes a belt conveyor frame and a CPC centering control system 1. The CPC centering control system 1 includes an infrared photoelectric detection sensor 11 and a digital amplifier 12. , processor 13, executive mechanism 14 and touch screen 15, described infrared photoelectric detection sensor 11 is installed on the front end of belt conveying frame, described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com