Digital location minimally invasive spine surgery 3D printing guide plate and manufacturing method

A 3D printing, minimally invasive surgery technology, applied in the field of medical devices and 3D printing guide plates, can solve the problems of poor accuracy, unavoidable dependence, and cumbersome guide plate positioning process, so as to improve medical safety, reduce impact, and improve matching degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation method of 3D printing guide plate for digital positioning spinal minimally invasive surgery

[0044] A method for preparing a 3D printing guide plate for digitally positioned spinal minimally invasive surgery provided by the present invention comprises the following steps:

[0045] (1) Positioning: The subject is placed prone on the 3D printed spinal surgery prone position frame. The CT scanning position is consistent with the position during the operation. Place the positioning block (7) on the skin near the centerline of the patient's spine near the operation area. and mark it.

[0046] (2) CT scanning: use a multi-row CT machine to scan the torso of the tested object, and store the relevant data information of the tested object.

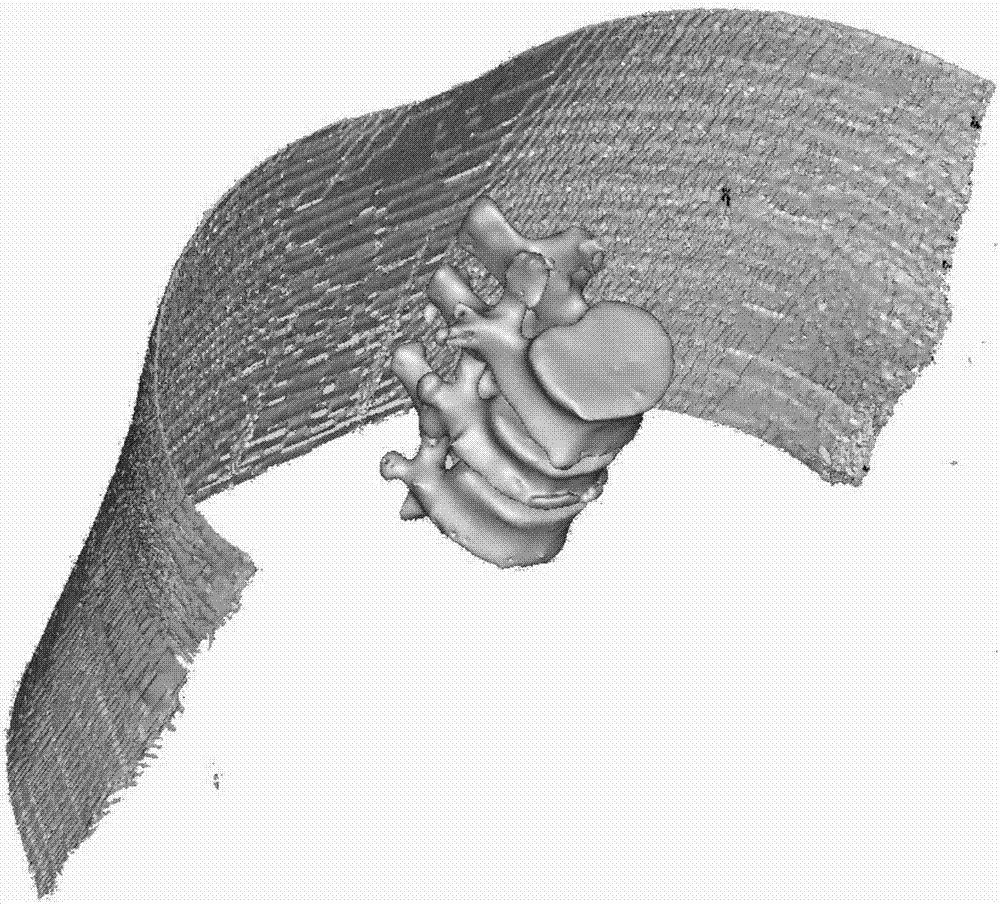

[0047] (2) Data segmentation in medical imaging software: Import CT scan data into medical imaging software for processing, use threshold segmentation method and Boolean operation summation, display vertebral body an...

Embodiment 2

[0054] Embodiment 2: Acquisition and labeling of CT data

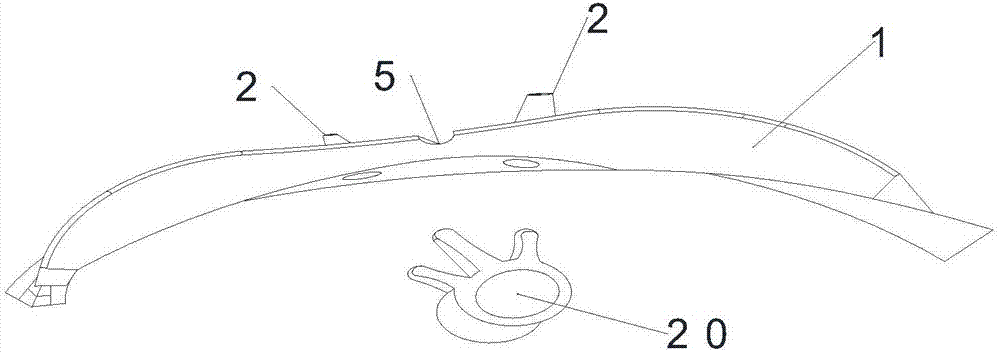

[0055] In the present invention, the body position of the tested subject's CT is consistent with the final position of the guide plate (1), and the tested subject is placed in a prone position on the body position frame to ensure that the tested subject's vertebral body (20) and skin form are relatively constant. Prevent serious errors caused by soft tissue deformation caused by body position changes on the surface of the fitting guide plate, and its relative position is consistent with the height when the guide plate (1) is finally used. Standard point, place a positioning block (7) on the spine centerline of the tested object, and mark the contact edge between the positioning block (7) and the skin on the skin with a waterproof marking pen.

[0056] A multi-row CT machine is used to scan the torso of the tested object and store relevant information of the tested object.

Embodiment 3

[0057] Embodiment three: computer-aided design

[0058] In the present invention, the skin-fitting surface data of the main part of the guide plate (1) is obtained by holding up the tester on the body position frame, which can ensure that the guide plate (1) prepared according to the tester’s skin data is accurate and reliable; For CT, the skin on the back must be flat, and the fitting surface of the produced guide plate is flat. During the operation, the prone position is performed, and the curved surface of the skin behind the arch is deformed; the rest of the guide plate (1) is stretched by the periphery of the skin. Order and pruning order can ensure that the guide plate (1) fits the skin as closely as possible, and ensure that the stretched height is parallel to the upper and lower edges of the vertebral body (20) inserted into the lesion, and the positioning block cavity (3) is reserved in the design ; The design of the guide hole (2) is based on the upper and lower edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com