Wall-breaking jet milling equipment for ganoderma lucidum spore powder

A Ganoderma lucidum spore powder and jet crushing technology, which is applied in grain processing, coating, etc., can solve the problems of reducing the thickness of the hysteresis layer on the surface of the target plate, affecting the effect of powder crushing, easy wear and heat, etc., and achieves low production cost and design Reasonable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

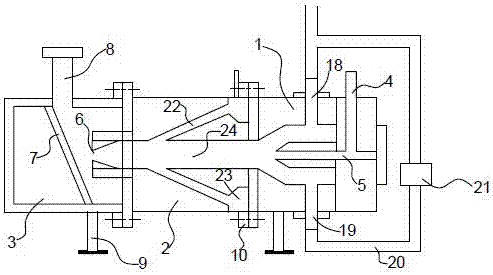

[0020] Such as figure 1 , 2 As shown, a wall-breaking air jet pulverization equipment for Ganoderma lucidum spore powder includes a feeding chamber 1, a mixing chamber 2, and a wall-breaking chamber 3. One side of the feeding chamber 1 is connected to a high-pressure inlet pipe 4, and the high-pressure inlet pipe 4 is connected In the gas injection pipe 5, the gas injection pipe 5 is connected to the gas-material mixing chamber 24 in the mixing chamber 2. One end of the gas-material mixing chamber 24 is provided with a gas nozzle 6 which is connected to the broken wall 3 The wall chamber 3 is provided with a baffle 7 which is arranged obliquely, and the upper end of the wall chamber 3 is provided with a gas outlet 8.

[0021] The lower end of the equipment is equipped with a rack 9 supporting the device, and the lower end of the rack 9 is equipped with anti-skid pads. The rack 9 is used to stabilize the vibration or shaking of the entire device during operation. The anti-skid pad ...

Embodiment 2

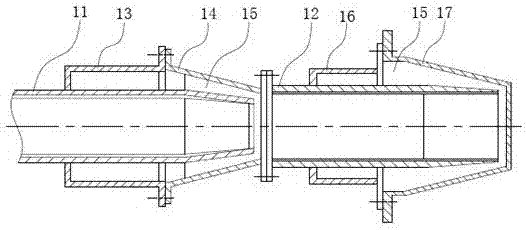

[0029] Such as figure 1 , 2 As shown, a wall-breaking airflow crushing device for Ganoderma lucidum spore powder. In actual work, the operator opens the entire device, connects the high-pressure airflow to the device through the high-pressure air inlet pipe 4, and feeds the Ganoderma spore powder from negative pressure The pipe 18 is put in, and the high-pressure airflow is transmitted to the jet pipe 5 through the high-pressure air inlet pipe 4. The jet pipe 5 is combined with the first jet pipe 11 and the second jet pipe 12, and the first jet pipe 11 enhances the flow rate of the high-pressure airflow. The second air injection pipe 12, the first air injection pipe 11 and the second air injection pipe 12 are respectively sheathed with an inner air ring branch 13 and an outer air ring branch 16 to reduce the spread of air flow, and one end of the first air injection tube 11 is designed into a conical shape. It can enhance the flow rate of the high-pressure airflow in the first j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com