Microbial straw decomposition additive as well as preparation method and application thereof

A straw decomposing agent and microbial technology, applied in the field of straw decomposing agent, can solve the problems of slow temperature rise and difficulty in rapid decomposing, and achieve the effects of accelerating straw decomposing, improving decomposing effect, saving decomposing process and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

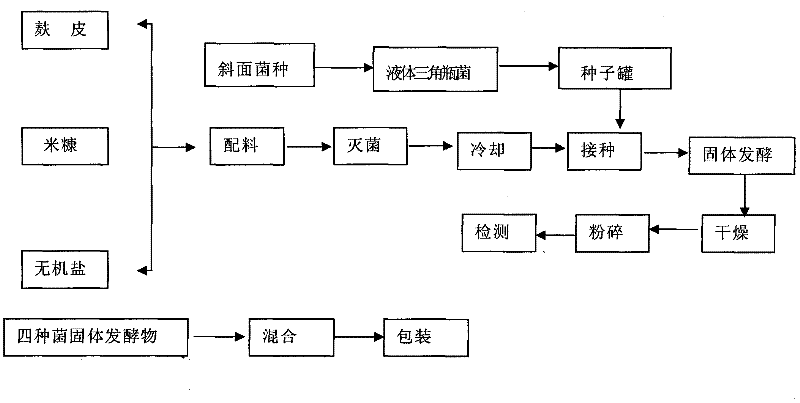

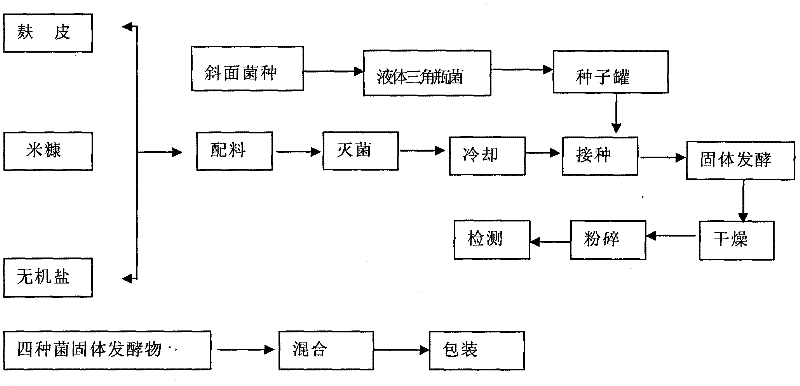

Image

Examples

preparation example Construction

[0034] Preparation of Preliminary Example 2 Aspergillus Niger Solid Inoculum

[0035] 1. Inoculate the Aspergillus niger species in the culture medium (the medium is prepared according to the formula provided by the supplier), store the culture medium slant seed strain in a refrigerator at 4°C, take it out and activate it twice before use, and transfer the activated strain to 250 ml eggplant bottle nutrient agar culture, culture temperature is 28 ℃, 48 hours when the growth is good, wash it with sterilized water, and use it as the inoculum of the seed tank;

[0036] 2. Add culture medium to a 1 ton fermenter, the composition of which is: 50% bran, 49% rice bran, 0.5% each of ammonium sulfate and potassium dihydrogen phosphate; the initial pH is 7.5; the ratio of feed to water before inoculation is 1 : 0.6. Inoculate the production tank from the seed tank to start fermentation. Fermentation conditions: culture temperature is 28°C, ventilation rate is 1:1.1, tank pressure is 0...

Embodiment 1

[0043] Embodiment 1 Preparation of microbial straw decomposing agent of the present invention

[0044] 1. Weigh each inoculum according to the following weight: Bacillus subtilis inoculum 3kg, Aspergillus niger inoculum 2kg, Trichoderma reesei inoculum 3kg, Saccharomyces cerevisiae inoculum 1kg;

[0045] 2. Dry and pulverize the four kinds of bacterial agents, and mix them evenly to obtain the product.

Embodiment 2

[0046] Example 2 Preparation of microbial straw decomposing agent of the present invention

[0047] 1. Weigh each inoculum according to the following weight: Bacillus subtilis inoculum 2kg, Aspergillus niger inoculum 1kg, Trichoderma reesei inoculum 2kg, Saccharomyces cerevisiae inoculum 0.5kg;

[0048] 2. Dry and pulverize the four kinds of bacterial agents, and mix them evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com