Lithium battery rolling mill thickness gauge

A technology of thickness gauge and lithium battery, which is applied in the field of thickness gauge, can solve the problems of large pollution of inspectors, incomplete processing function, inaccurate measurement, etc., and achieve the effects of saving manpower, no environmental pollution, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

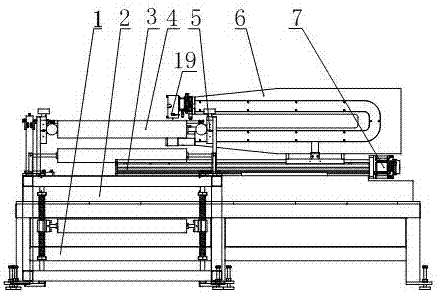

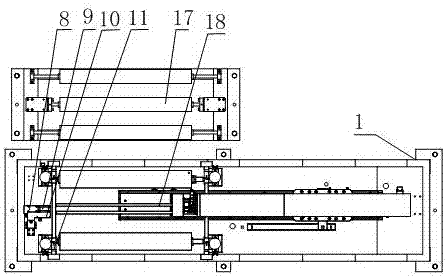

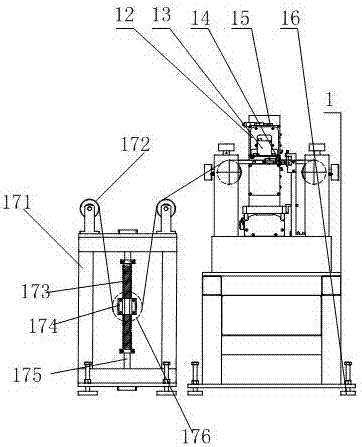

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0013] Such as Figure 1 to Figure 3 As shown, the lithium battery rolling mill thickness gauge of the present invention includes a carbon steel chassis 1, a marble installation platform 2, a linear module 3, a guide roller 4, a guide roller longitudinal adjustment seat 5, a marble C-shaped scanning frame 6, a servo motor 7, Calibration sheet blowing plate 8, calibration sheet 9, calibration sheet mounting plate 10, guide roller lateral adjustment seat 11, laser probe installation box 12, laser sensor 13, lower probe blowing plate 14, XYZ axis slide table 15, adjustment foot 16 , buffer mechanism 17, roller 18, photoelectric sensor 19, a marble installation platform 2 is installed on the carbon steel chassis 1, the marble installation platform 2 is connected with the linear module 3, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com