Height-adjustable automatic feeding machining machine

An automatic feeding and processing machine technology, applied in metal processing and other directions, can solve the problems of the feeding mechanism stuck and leaking, and achieve the effect of reducing the failure rate, stable and reliable performance, and improving feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

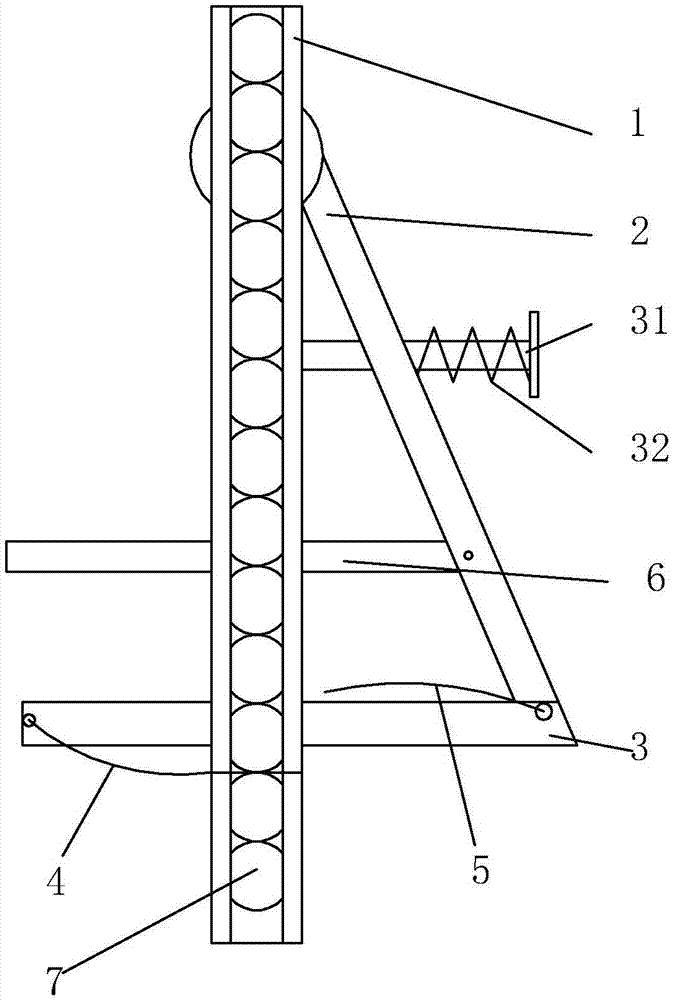

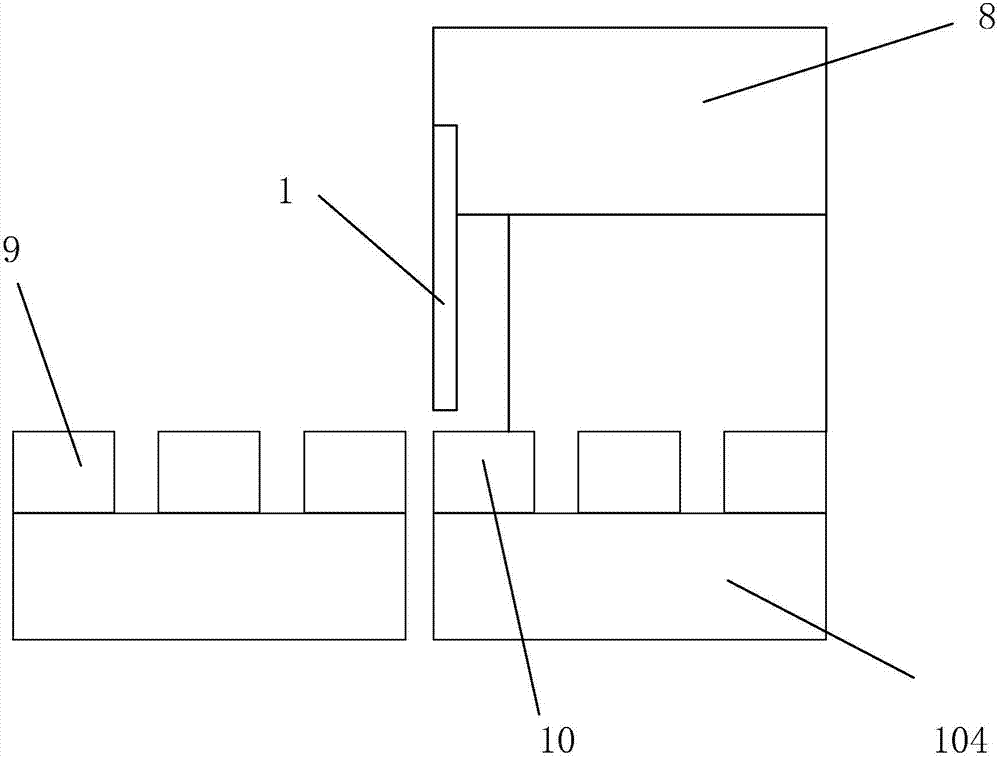

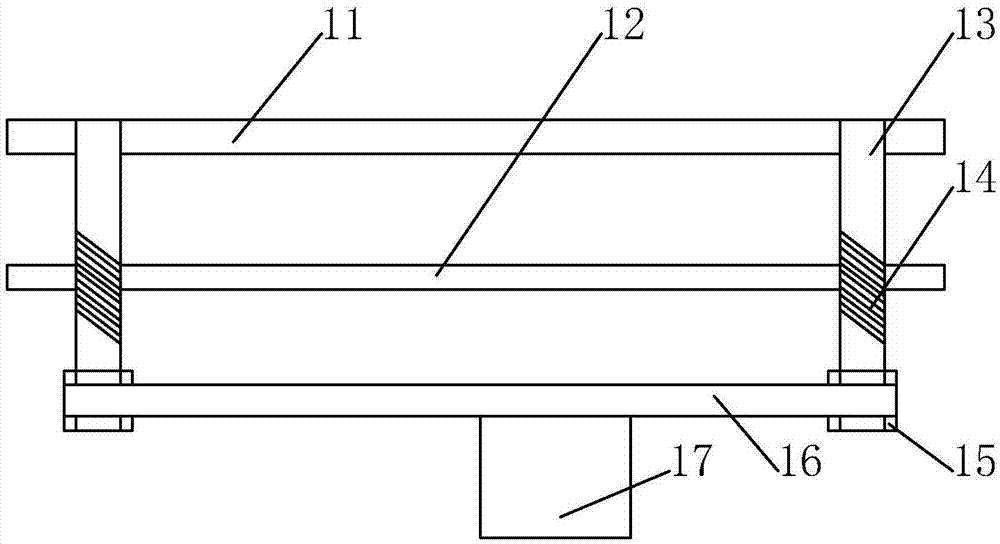

[0024] The invention provides a height-adjustable automatic feeding processing machine. The invention provides a height-adjustable automatic feeding processing machine, which includes a vibrating plate 8, a guide rail 1, a reciprocating feeding mechanism 10, and four stations Rotary deburring machine 9; the bottom of the above-mentioned guide rail 1 is connected with a swing rod 2 on an inclined axis, the end of the above-mentioned swing rod 2 is provided with a cross bar 3 placed at the bottom of the above-mentioned guide rail 1, and the two ends of the above-mentioned cross rod are respectively provided with The left limiting piece 4 and the right limiting piece 5, the waist of the above-mentioned fork 3 is connected with an eccentric mechanism. The left and right limiters are arc-shaped so as to match the swing arc of the fork.

[0025] The present invention is further provided that a guide rod 31 and a return spring 32 are further provided between the above-mentioned swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com