Clamping device used for assembling of aluminum alloy hull and manufacturing method thereof

A technology of hull assembly and aluminum alloy, applied in the direction of assembly machine, auxiliary device, ship construction, etc., can solve the problems of difficult control, large thermal expansion coefficient, large deformation, etc., and achieve the effect of convenient force application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

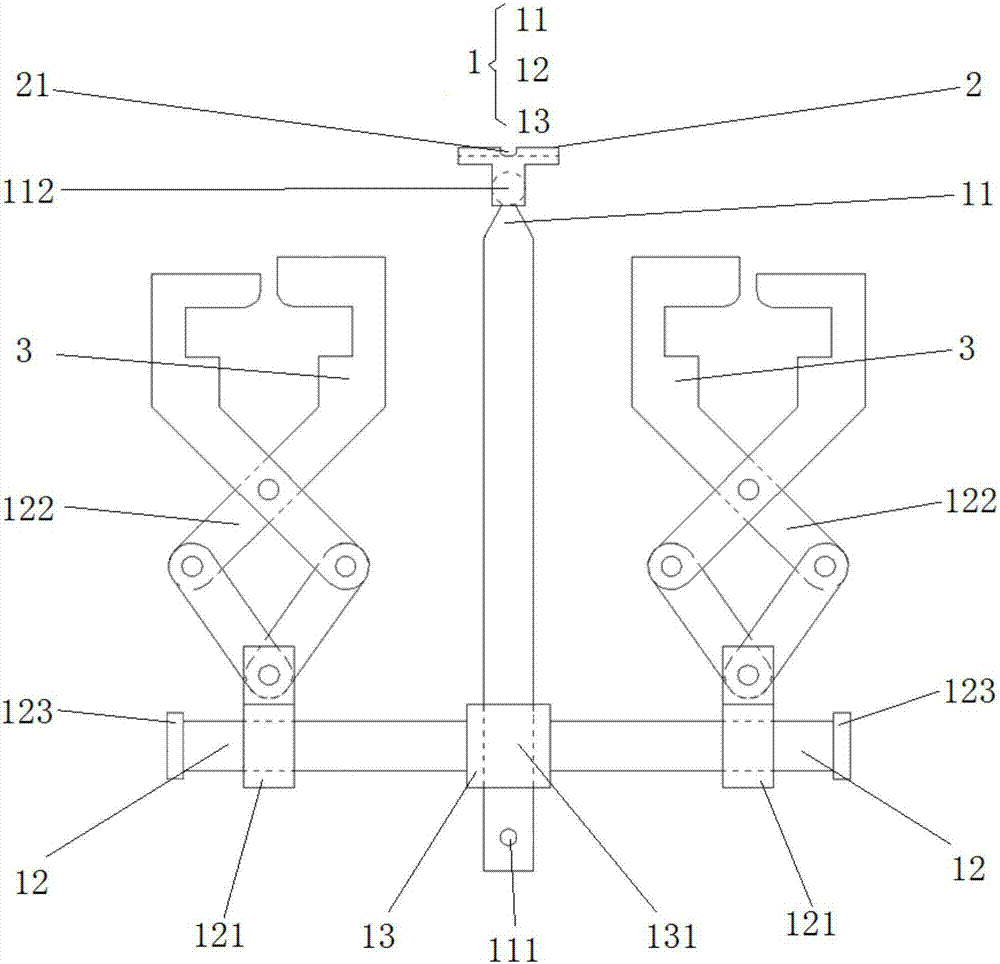

[0036] (S1) welding the first ends of the second support members 12 to the opposite sides of the positioning support 13;

[0037] (S2) Assemble the first support 11 and the internal threaded hole 131 on the positioning support 13 by manual rotation. After the assembly is completed, install the handle to the mounting hole at the first end of the first support 11 111 in;

[0038] (S3) After the sleeve 121 is sleeved on the second support member 12, the limiting plate 123 is welded to the second end of the second support member 12;

[0039] (S4) After first connecting the clamp 3 with the chain plate 122, then install the chain plate 122 on the sleeve 121 through a nut (or first install the chain plate 122 on the sleeve 121 through a nut, and then install the clamp 3 be connected with chain plate 122);

[0040] ( S5 ) Embedding the anchor 2 into the connecting ball 112 at the second end of the first support 11 .

Embodiment 2

[0042] (S1) The second support 12 adopts surface polishing treatment of a cuboid steel casting with a length of 170 mm, a thickness of 30 mm, and a width of 30 mm;

[0043] (S2) The positioning support 13 adopts a square steel casting with a side length of 50 mm, an inner diameter of 15 mm, and an internal thread of M30×3.5;

[0044] (S3) The second support 12 and the positioning support 13 are directly connected by welding, the size of the welding foot is 5mm, and the axis of the second support 12 and the transverse axis of the positioning support 13 need to be in the same plane;

[0045] (S4) What the first support 11 adopts is that length is 400mm, the cylindrical steel casting of radius R=15mm, and the first end of the first support 11 is provided with outer diameter thread and is M30 * 3.5 profile thread;

[0046] (S5) After the first end of the first support 11 is matched with the internal threaded hole on the positioning support 13 for installation, manually insert the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com