Automatic cutting and separating device for cauliflower

An automatic cutting and separating device technology, applied in the direction of metal processing, etc., can solve the problems of low economic income, low cutting efficiency, time-consuming and other problems of cauliflower, and achieve the effects of promoting popularization, reducing labor dependence, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

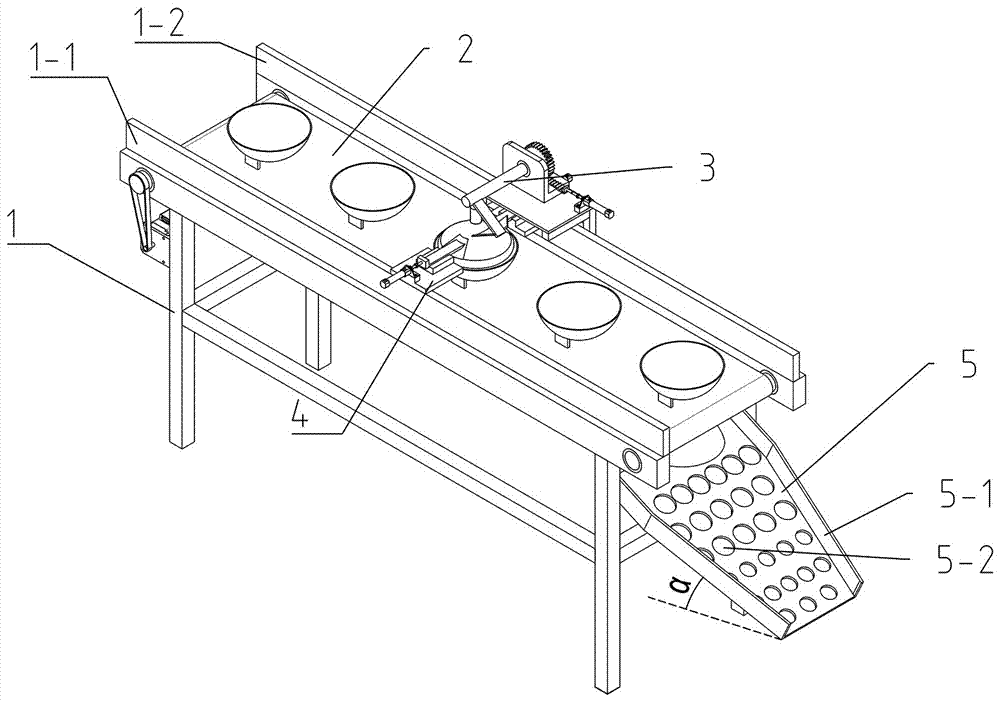

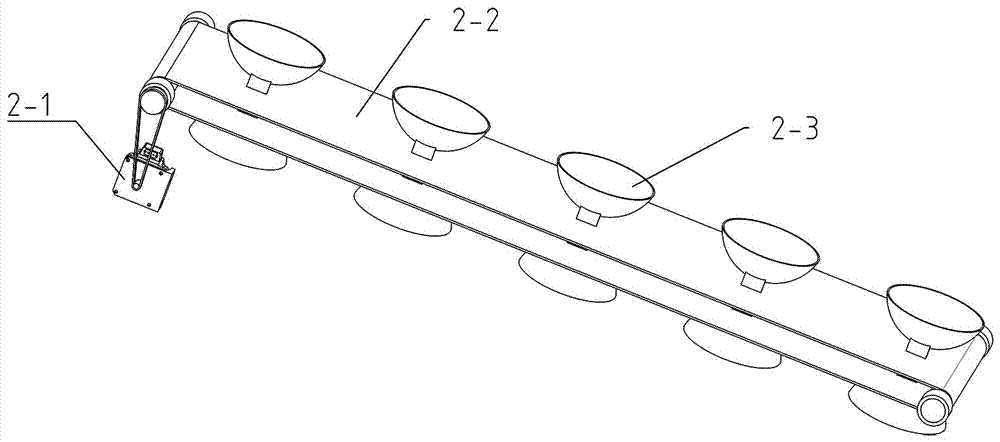

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a cauliflower automatic cutting and separating device includes a transmission mechanism 2, a cutting mechanism 3, a pressing mechanism 4 and a separation mechanism 5, and is characterized in that: the transmission mechanism 2 includes a transmission belt 2-2 and a discharge trough 2- 3. The transmission mechanism 2 is set between the left baffle 1-1 and the right baffle 1-2, and the discharge troughs 2-3 are arranged at intervals so that the cut flower stems fall into the interval under the action of inertia. Inside, send out along with described conveyer belt 2-2;

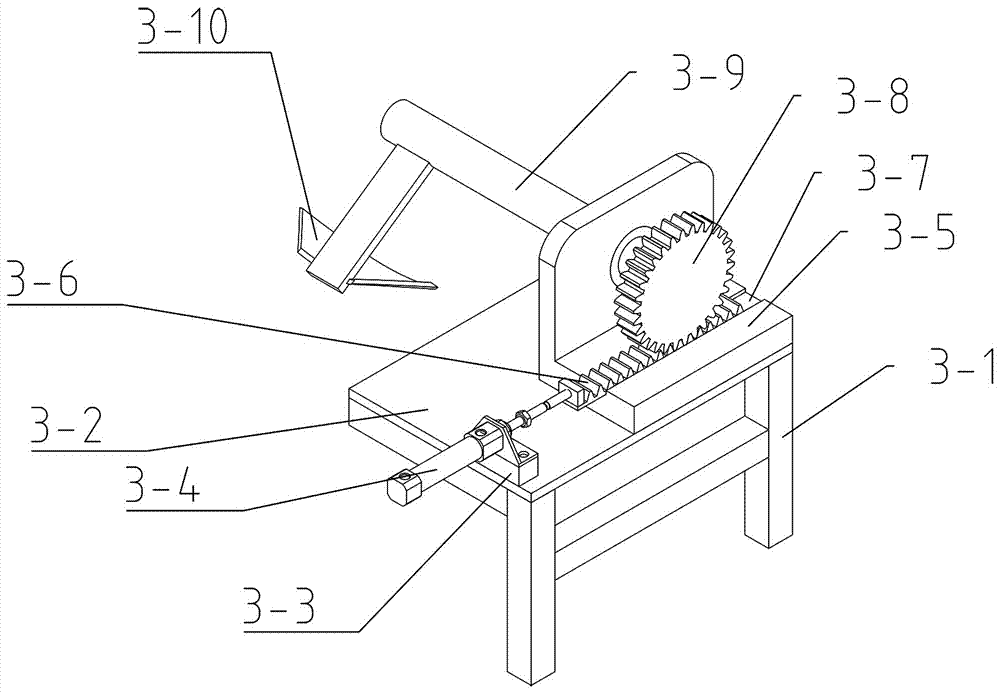

[0025] The cutting mechanism 3 is provided with an arc-shaped cutting hoe 3-10 with an arc-shaped cutting movement. Located above one of the pressing mechanisms and fixedly connected to the side baffle, the cutting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com