Edge removing and screening machine for O-shaped rings

A technology of O-rings and screening machines, which is applied in applications, household components, household appliances, etc., can solve the problems of difficult edge screening operation, poor effect, complex equipment structure, etc. Thorough, automated high-length effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

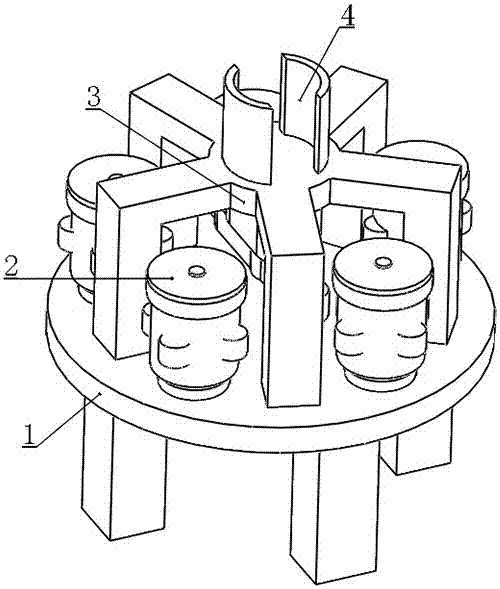

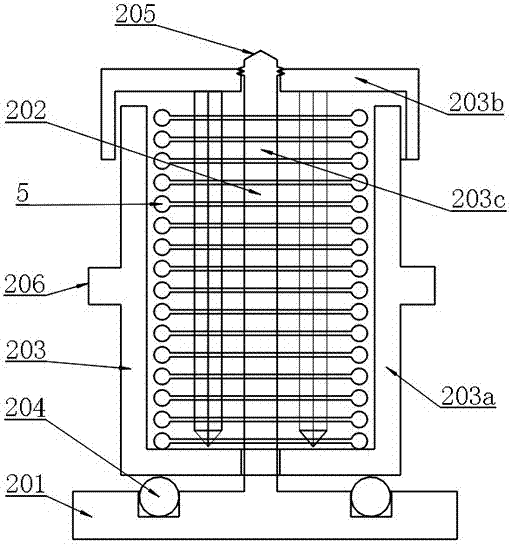

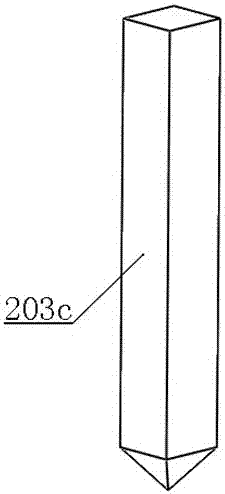

[0027] Example: as attached figure 1 , 2 , 3, 4, 5, 6 and attached Figure 7 As shown, a side removal and screening machine for O-rings includes a frame 1, which is arranged on the frame 1 and is used to remove the O-ring wool 5 through relative rotation and cutting and side removal. The edge-removing cylindrical body part 2 that is screened, and the method that is arranged on the frame 1 and rotates by driving the edge-removing cylindrical part 2 is used for cutting and dismantling by the edge-removing cylindrical part 2 The driving part 3 of the side, and several cylindrical parts 2 for removing the side are arranged on the frame 1 in a circular arrangement.

[0028] In this embodiment, the O-ring wool 5 includes an O-ring itself 501 and a circular O-ring burr 502 adhered inside the O-ring itself 501 .

[0029] On the other hand, the cylinder part 2 for edge removal is used to place the stacked O-ring wool 5, so that when the cylinder part 2 for edge removal is rotated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com