Asphalt roll and preparation method thereof

A technology of asphalt and coiled materials, which is applied to chemical instruments and methods, building insulation materials, and other household appliances. It can solve the problems of troublesome construction and difficult peeling, and reduce the construction time, ensure the function and safety factor, and reduce the heat. The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

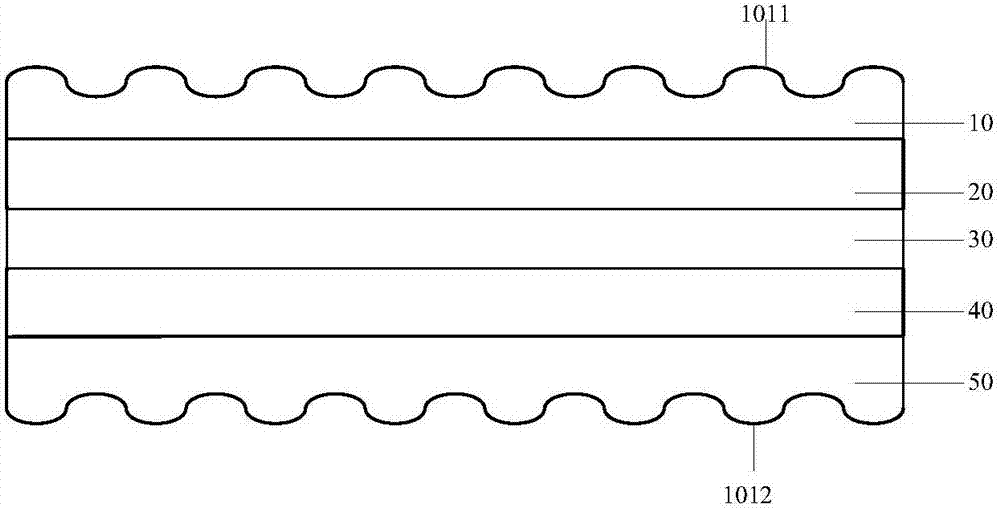

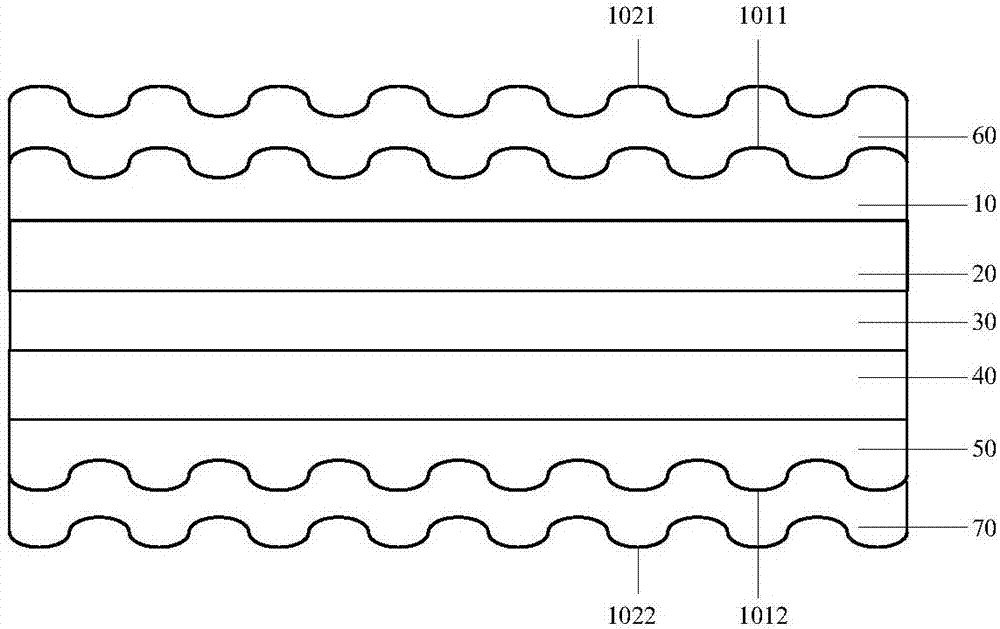

[0025] see figure 1 , the present embodiment provides an asphalt coil, including a first isolation layer 10, a first asphalt layer 20, a base tire layer 30, a second asphalt layer 40 and a second isolation layer 50 stacked sequentially from top to bottom. A surface of the isolation layer 10 away from the first asphalt layer 20 is provided with uneven first upper patterns 1011, and a surface of the second isolation layer 50 away from the second asphalt layer 40 is also provided with uneven first lower patterns 1012, And both the first isolation layer 10 and the second isolation layer 50 are polycarbonate layers.

[0026] In this embodiment, the isolation layer on both sides of the asphalt coil is provided with uneven first patterns (the first pattern includes the first upper pattern 1011 and the first lower pattern 1012), the first pattern makes the surface of the isolation layer With the increase of friction, it is easier for construction workers to tear off the uneven isolat...

Embodiment 2

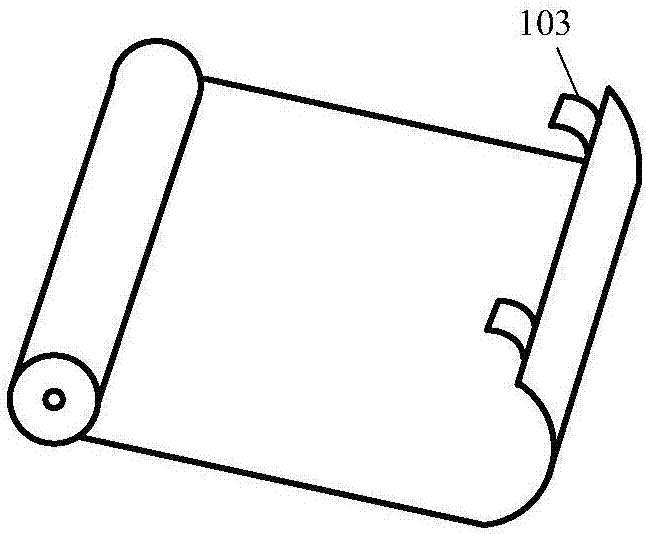

[0044] see Figure 4 , the present embodiment provides a kind of preparation method of asphalt coil, comprising:

[0045] Step S1: unfolding the base tire layer;

[0046] Step S2: Make the sprayed base tire layer pass through the oil immersion tank for asphalt pre-impregnation;

[0047] Step S3: passing the pre-impregnated base tire layer through the oiling tank, performing a second asphalt impregnation, forming a first asphalt layer on the upper surface of the base tire layer, and forming a second asphalt layer on the lower surface of the base tire layer;

[0048] Step S4: using polycarbonate to form a first isolation layer on the side of the first asphalt layer away from the base layer, and using polycarbonate to form a second isolation layer on the side of the second asphalt layer away from the base layer;

[0049] Step S5: forming a rough first upper pattern on the surface of the first isolation layer away from the first asphalt layer, and forming a first uneven lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com