Robot intelligent up-and-down printed circuit board system and circuit board transfer method

A printed circuit board, robot intelligence technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that affect the detection efficiency, prolong the time of board loading and unloading, and increase the complexity of the operation time of the mechanical arm, so as to improve the detection efficiency , shorten the exercise time, shorten the effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

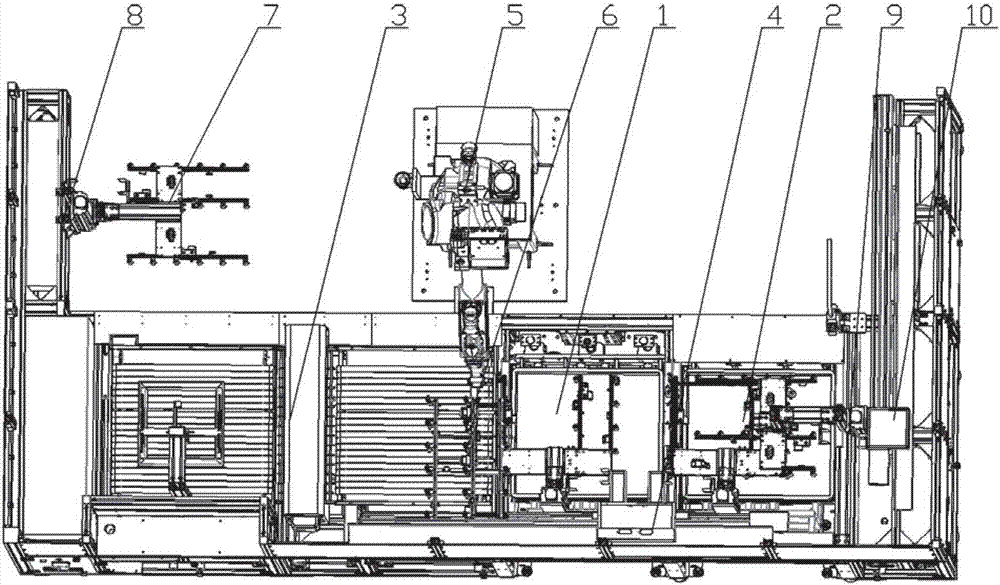

[0027] Such as figure 1 As shown, a robot intelligent upper and lower printed circuit board system provided by the present invention includes a feeding device 1, a discharging device 2, a dust sticking machine 3, a double transfer device 4, an image sensor (not shown in the figure), a robot 5 , the manipulator gripper 6, the first auxiliary gripper 7, the first vertical movement mechanism 8, the plate taking device 9 and the first longitudinal movement mechanism 10, the discharge device 2, the feeding device 1 and the dust sticking machine 3 from right to Arranged side by side on the left side, the double transfer device 4 is arranged above the discharging device 2, the feeding device 1 and the dust sticking machine 3, the robot 5 is opposite to the feeding device 1 and the dust sticking machine 3, and the manipulator clamp 6 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com