Mineral coagulant aid for treating water and preparation method thereof

A coagulant aid and water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as safety hazards, residues, and biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

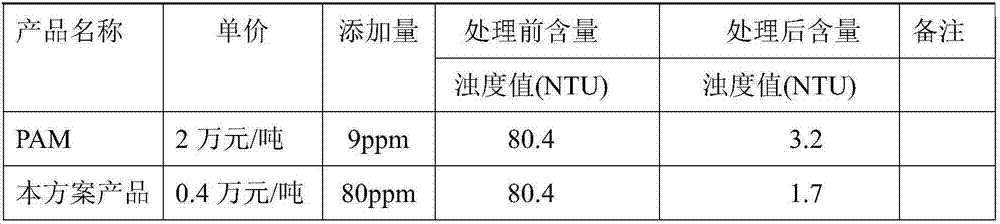

Embodiment 1

[0022] In this embodiment, the mineral coagulant used for water treatment includes silicate and chitosan, and the mass ratio of silicate and chitosan is 20:1.

[0023] The silicate is sepiolite, porphyllite, vermiculite or attapulgite.

[0024] The mineral coagulation aid is prepared by the following method, specifically comprising the following steps:

[0025] Add silicate to water at a solid-to-liquid ratio of 1:5 to form a silicate solution; add dispersant with a mass percentage of 0.1% to the silicate solution, and stir the silicate solution at a speed of 600 rpm 7 minutes; the silicate solution was carried out sedimentation and separation, and the upper suspended matter was carried out; the upper suspended matter was subjected to solid-liquid separation, and the solid was taken as an intermediate solid product; chitosan was added to glacial acetic acid, and the ratio of chitosan to glacial acetic acid was 1 gram: 1 liter, the first mixed solution was formed after stirrin...

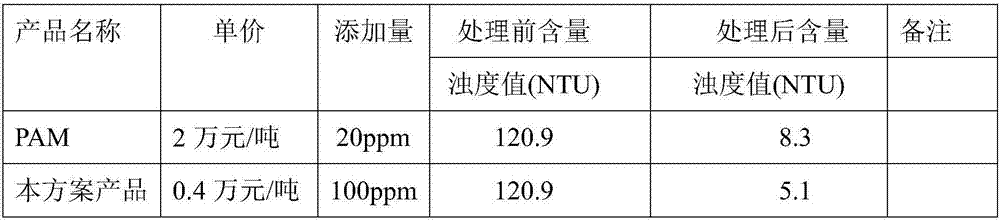

Embodiment 2

[0031] In this embodiment, the mineral coagulant used for water treatment includes silicate and chitosan, and the mass ratio of silicate and chitosan is 30:1.

[0032] The silicate is sepiolite, porphyllite, vermiculite or attapulgite.

[0033] The mineral coagulation aid is prepared by the following method, specifically comprising the following steps:

[0034] Add silicate to water at a solid-to-liquid ratio of 1:6 to form a silicate solution; add 0.2% dispersant to the silicate solution, and stir the silicate solution at a speed of 700 rpm 8 minutes; the silicate solution is carried out sedimentation and separation, and the upper suspension is taken; the upper suspension is separated into solid and liquid, and the solid is taken as an intermediate solid product; chitosan is added to glacial acetic acid, and the ratio of chitosan to glacial acetic acid is 2 grams: 1 liter, after stirring for 3.5 hours, the first mixed solution was formed; the intermediate solid product was a...

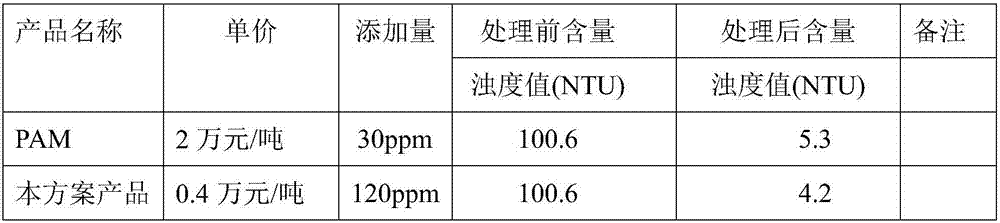

Embodiment 3

[0040] In this embodiment, the mineral coagulant used for water treatment includes silicate and chitosan, and the mass ratio of silicate and chitosan is 39:1.

[0041] The silicate is sepiolite, porphyllite, vermiculite or attapulgite.

[0042] The mineral coagulation aid is prepared by the following method, specifically comprising the following steps:

[0043] Add silicate to water at a solid-to-liquid ratio of 1:7 to form a silicate solution; add 0.3% dispersant to the silicate solution, and stir the silicate solution at a speed of 800 rpm 9 minutes; the silicate solution is carried out sedimentation and separation, and the upper suspension is taken; the upper suspension is separated into solid and liquid, and the solid is taken as an intermediate solid product; chitosan is added to glacial acetic acid, and the ratio of chitosan to glacial acetic acid is 3 grams: 1 liter, the first mixed solution was formed after stirring for 4 hours; the intermediate solid product was adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com