A kind of nano aluminum nitride powder and its preparation method and application

A nano-aluminum nitride and powder technology, applied in the field of ceramic materials, can solve the problems of easy agglomeration, large AlN particles and low purity, and achieve the effects of good crystallinity, complete decomposition and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

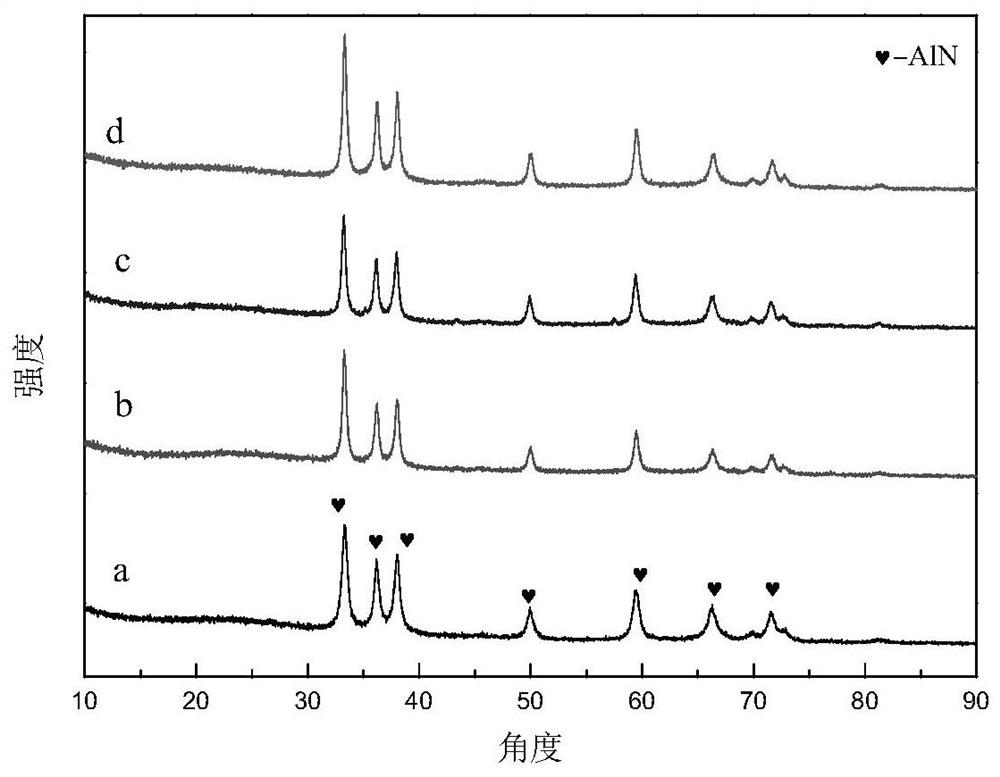

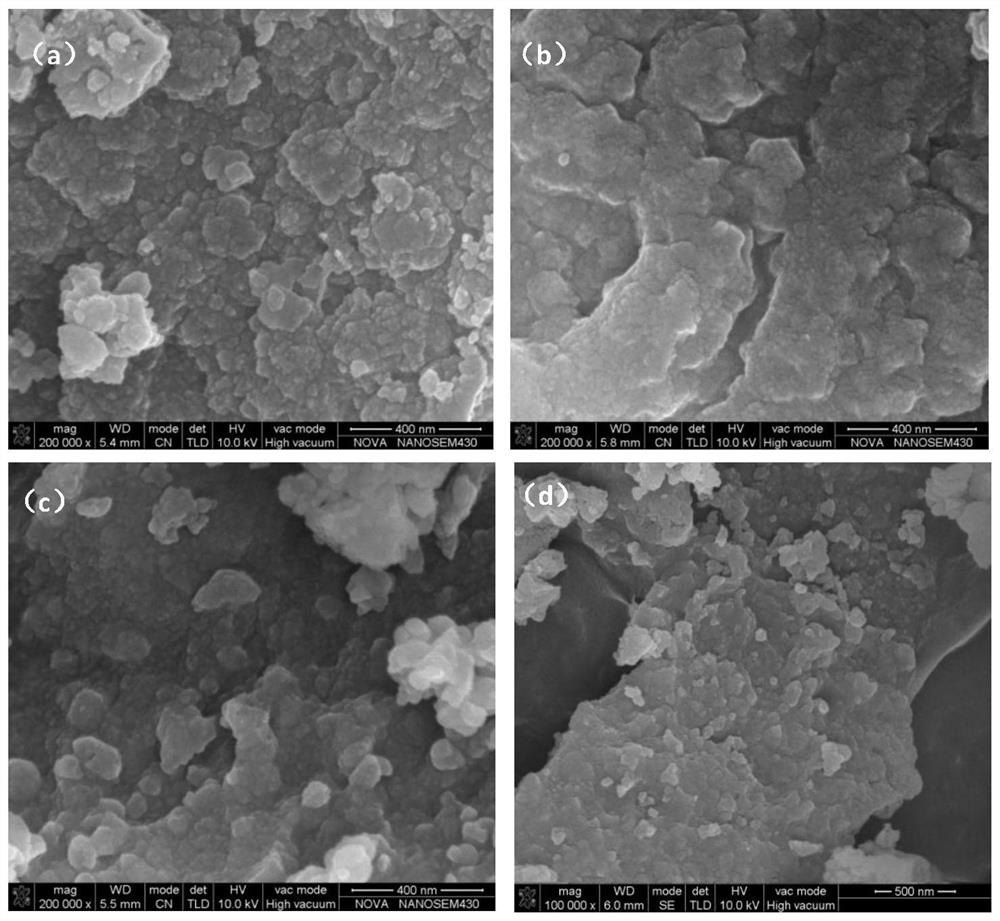

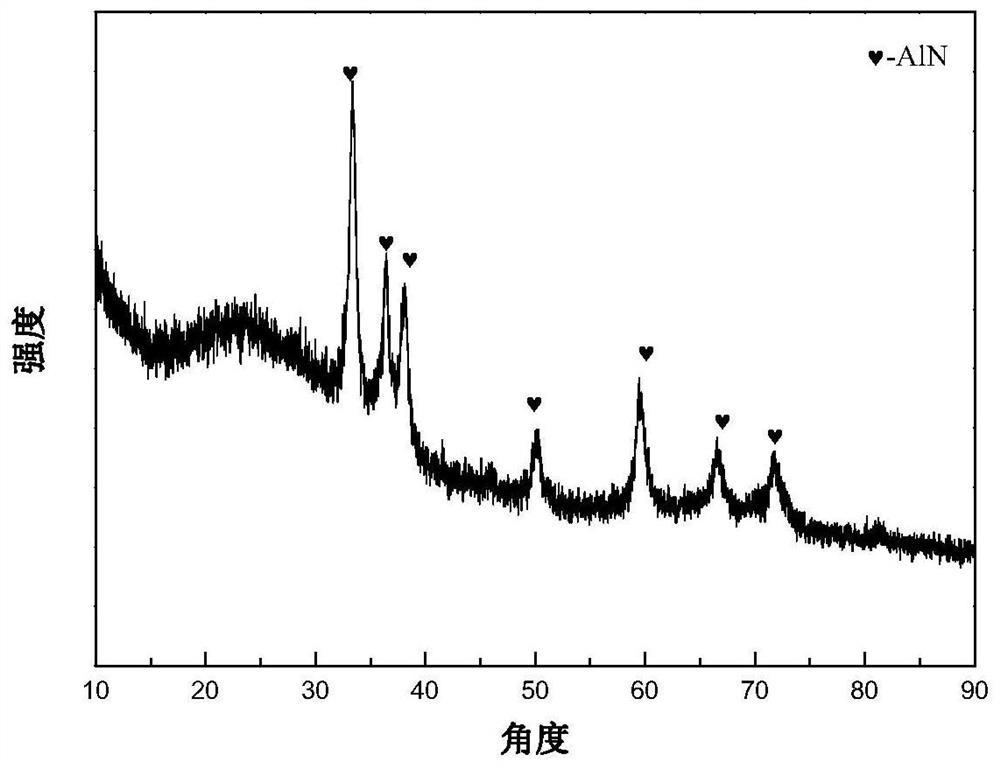

Embodiment 1

[0034] 1. Using aluminum chloride hydrate and dicyandiamide as raw materials, set the molar ratio of dicyandiamide / aluminum chloride to 3:1, weigh 1g of aluminum chloride hydrate and 1.04g of dicyandiamide, and add an appropriate amount of aluminum chloride ( AlCl 3 ·6H 2 O, 99.99%) and dicyandiamide (C 2 h 4 N 4 , 99%) were dissolved in methanol at 30°C, and after being completely dissolved, the dicyandiamide solution was slowly added to the aluminum chloride solution while stirring to obtain a clear and stable precursor salt solution, and the solution was put into an oven drying to obtain precursor salt powder;

[0035] 2. Put the precursor salt powder into an alumina crucible, and calcine it at 1000°C under the protection of a nitrogen atmosphere. The holding time is 5 hours, the heating rate is 3°C / min, and the nitrogen flow rate is 0.4L / min to obtain nano-nitridation Aluminum powder.

Embodiment 2

[0037] 1. Using aluminum chloride hydrate and dicyandiamide as raw materials, set the molar ratio of dicyandiamide / aluminum chloride to 4:1, weigh 1g of aluminum chloride hydrate and 1.39g of dicyandiamide, and add an appropriate amount of aluminum chloride ( AlCl 3 ·6H 2 O, 99.99%) and dicyandiamide (C 2 h 4 N 4 , 99%) were dissolved in methanol at 30°C, and after being completely dissolved, the dicyandiamide solution was slowly added to the aluminum chloride solution while stirring to obtain a clear and stable precursor salt solution, and the solution was put into an oven drying to obtain precursor salt powder;

[0038] 2. According to the preparation process in Example 1, under the protection of nitrogen atmosphere, calcination was carried out at 1000°C, the holding time was 5h, the heating rate was 3°C / min, and the nitrogen flow rate was 0.4L / min, to obtain nano-aluminum nitride powder .

Embodiment 3

[0040] 1. Using aluminum chloride hydrate and dicyandiamide as raw materials, set the molar ratio of dicyandiamide / aluminum chloride to 5:1, weigh 1g of aluminum chloride hydrate and 1.74g of dicyandiamide, and add an appropriate amount of aluminum chloride ( AlCl 3 ·6H 2 O, 99.99%) and dicyandiamide (C 2 h 4 N 4 , 99%) were dissolved in methanol at 30°C, and after being completely dissolved, the dicyandiamide solution was slowly added to the aluminum chloride solution while stirring to obtain a clear and stable precursor salt solution, and the solution was put into an oven drying to obtain precursor salt powder;

[0041] 2. According to the preparation process in Example 1, under the protection of nitrogen atmosphere, calcination was carried out at 1000°C, the holding time was 5h, the heating rate was 3°C / min, and the nitrogen flow rate was 0.4L / min, to obtain nano-aluminum nitride powder .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com