Mining method for outdoor quarry

A quarry and open-pit technology, applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as increasing infrastructure costs, increasing production costs, and prolonging production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

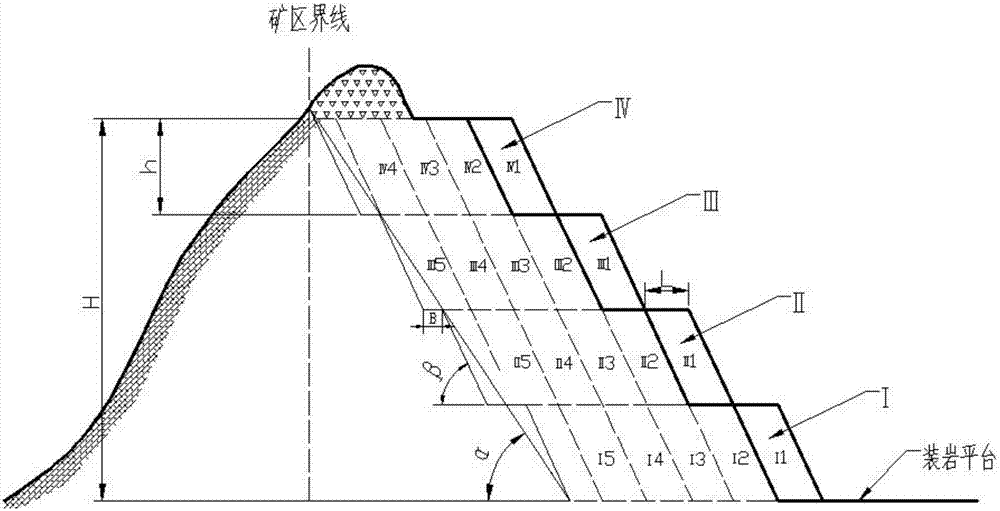

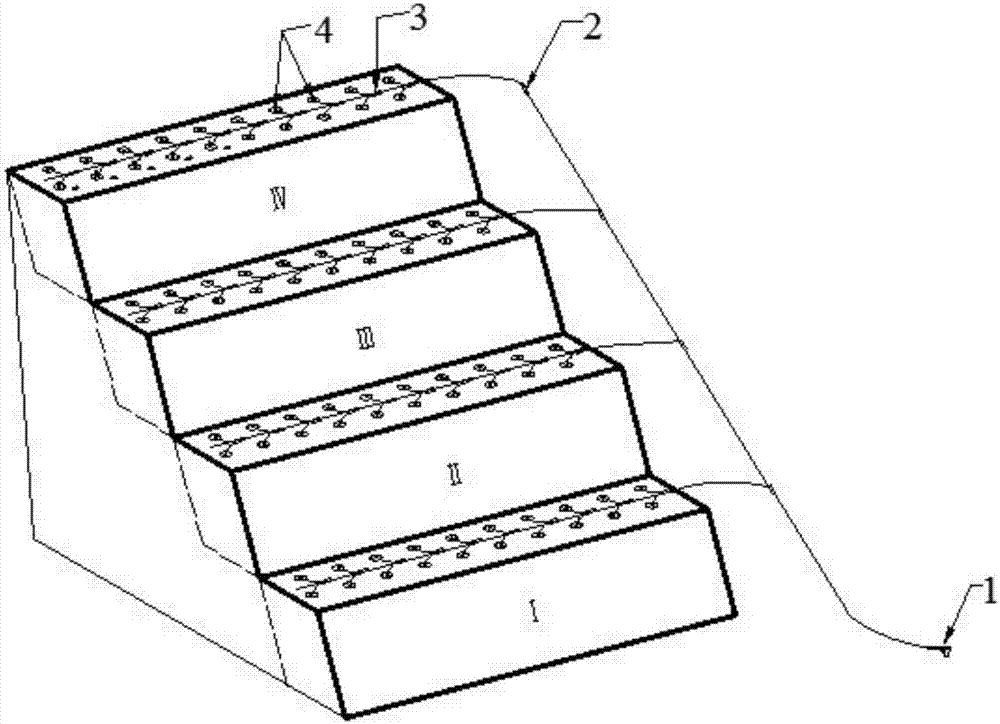

[0045] A limestone mining area is a low-mountain landform. The highest elevation of the mountain is +303.0m, the lowest elevation is +127.0m, and the relative elevation difference is 176.0m. The slope of the mountain slope is generally 60-80°, and the terrain is steep. It is located in mining area No. 8 to B The terrain at the turning point is relatively slow, and the mine has built an excavator uphill road to reach the +265m elevation of the mountain, with good transportation conditions.

[0046] The ore body between the +265~+220m elevation of the mine is mined by multi-layered millisecond blasting with a layered height of 15m and a total of 3 layers. Each layered rock drilling platform is divided into several ore blocks with a width of 6m and a length of 21m according to the order of mining. From the outside to the inside, they are 1, 2, 3, 4, 5...; each layered ore directly falls to the +220m shovel loading platform , It is shoveled by excavator and transported by car to the ...

Embodiment 2

[0092] Limestone ore body in a mining area is a medium-thick layered limestone of the Lower Permian Maokou Stage (P1q), distributed in the entire mining area, directly exposed on the surface, with an average length of 205m, a width of about 140m, and an elevation of +312.3~+ 205.0m. The natural slope of the surface is generally about 35-55°, and locally greater than 55°. The ore is of medium-hard grade. The limestone deposits are distributed on the steep slopes of the mining area, directly exposed on the surface, suitable for open-pit mining.

[0093] 1. Development

[0094] Build the excavator uphill path to the top of the mountain +312.3m, cut the top to form the initial platform for rock drilling with an elevation of +310m, and develop layered rock drilling platforms at the elevations of +295m, +280m, +250m, +235m, and +220m. Excavate the shovel loading platform at +265m and +205m.

[0095] The ore body between +265~+310m elevation is mined by multi-layered millisecond blasting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com