Error compensation system of grating ruler and method thereof

An error compensation and grating ruler technology, which is applied in the field of grating rulers, can solve problems such as poor accuracy of grating rulers, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

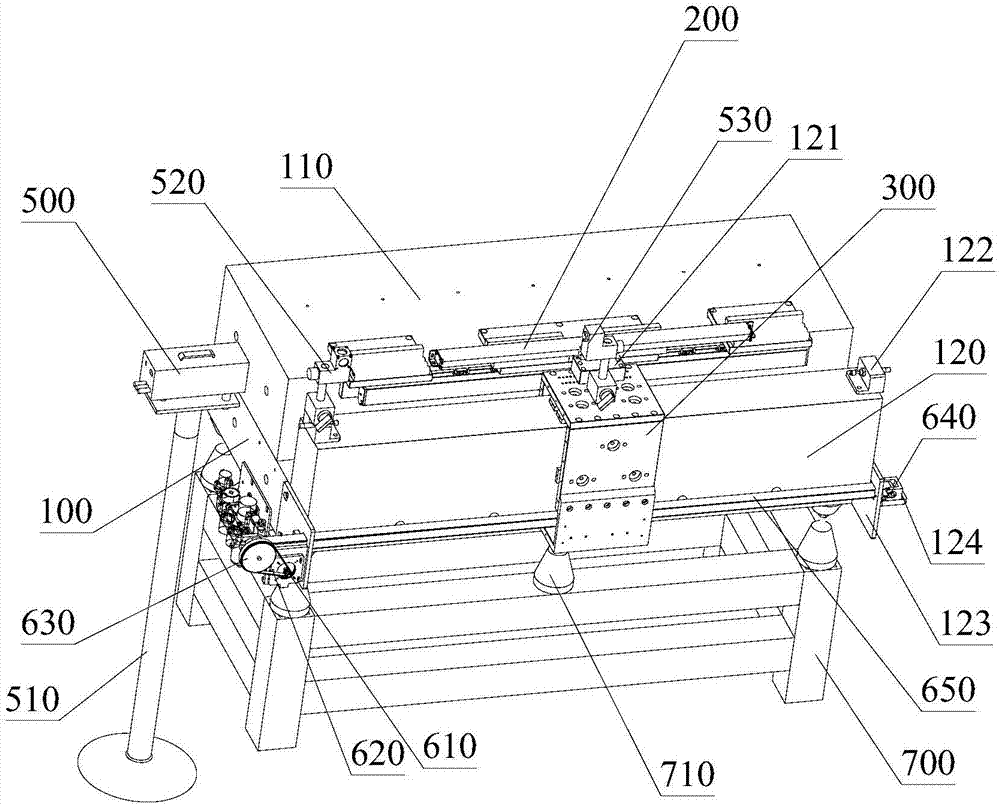

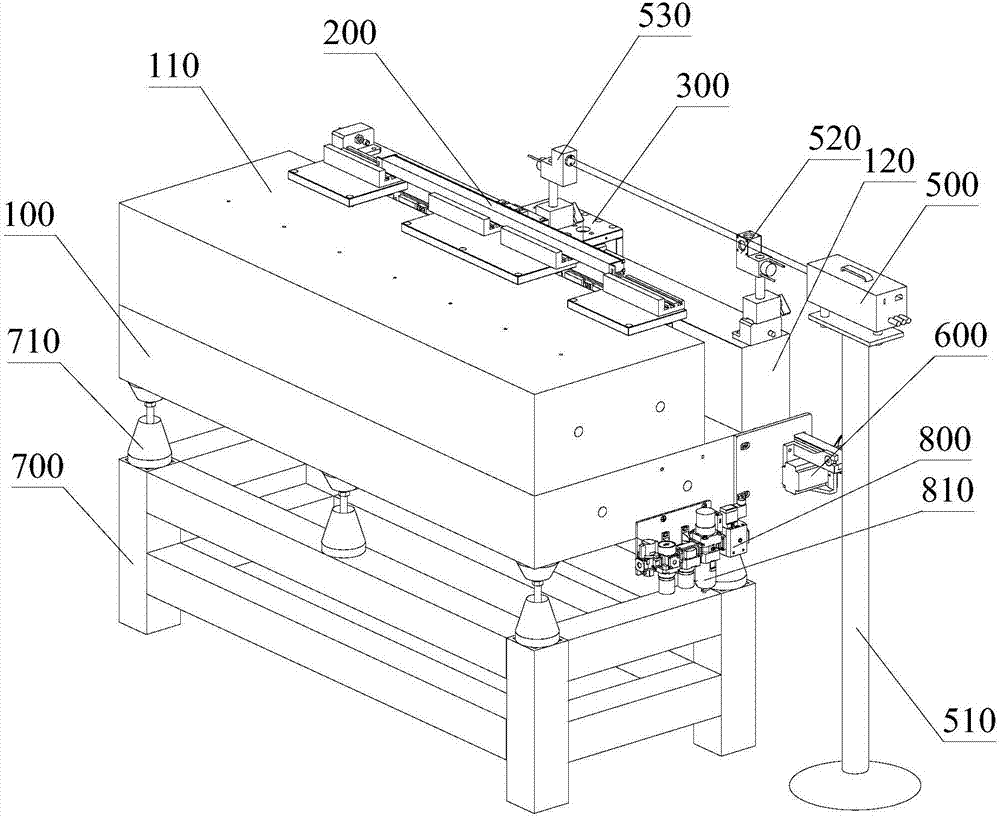

[0031] Such as figure 1 As shown, the present invention provides an error compensation system for a grating ruler, which includes a base, an air bearing sliding device and a laser interferometer.

[0032] The base includes a first platform 100 , a second platform 110 and a third platform 120 parallel to the top surface of the first platform 100 , and the top surface of the second platform 110 is provided with a grating scale 200 along its length direction.

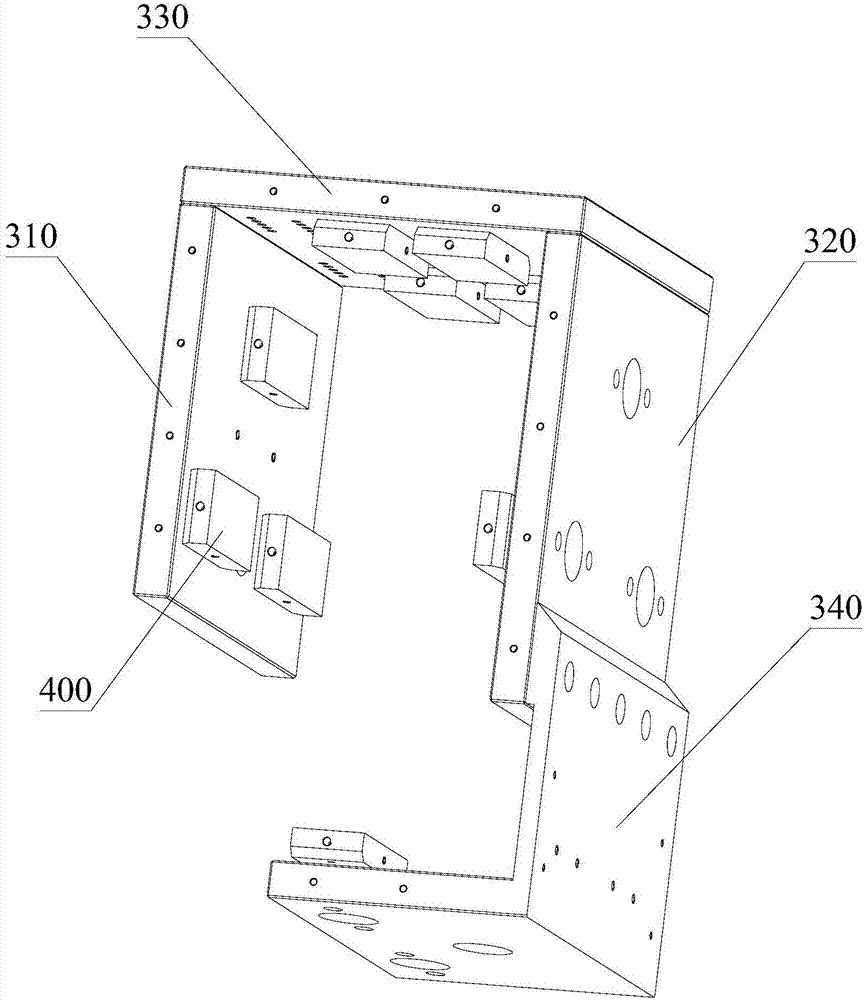

[0033] The air bearing sliding device includes a half-enclosed slider 300 arranged on the outer peripheral surface of the third platform 120 and each air bearing block 400 arranged on the inner wall of the half-enclosed slider 300, and the half-enclosed slider 300 is under the action of the driving device, Drive each air-floating block 400 to do linear motion on the outer peripheral surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com