Stirring, mixing and reduction device

A technology of stirring, mixing and dividing device, applied in measuring devices, analyzing materials, sampling, etc., can solve the problems of inconvenient feeding, dust leakage, environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

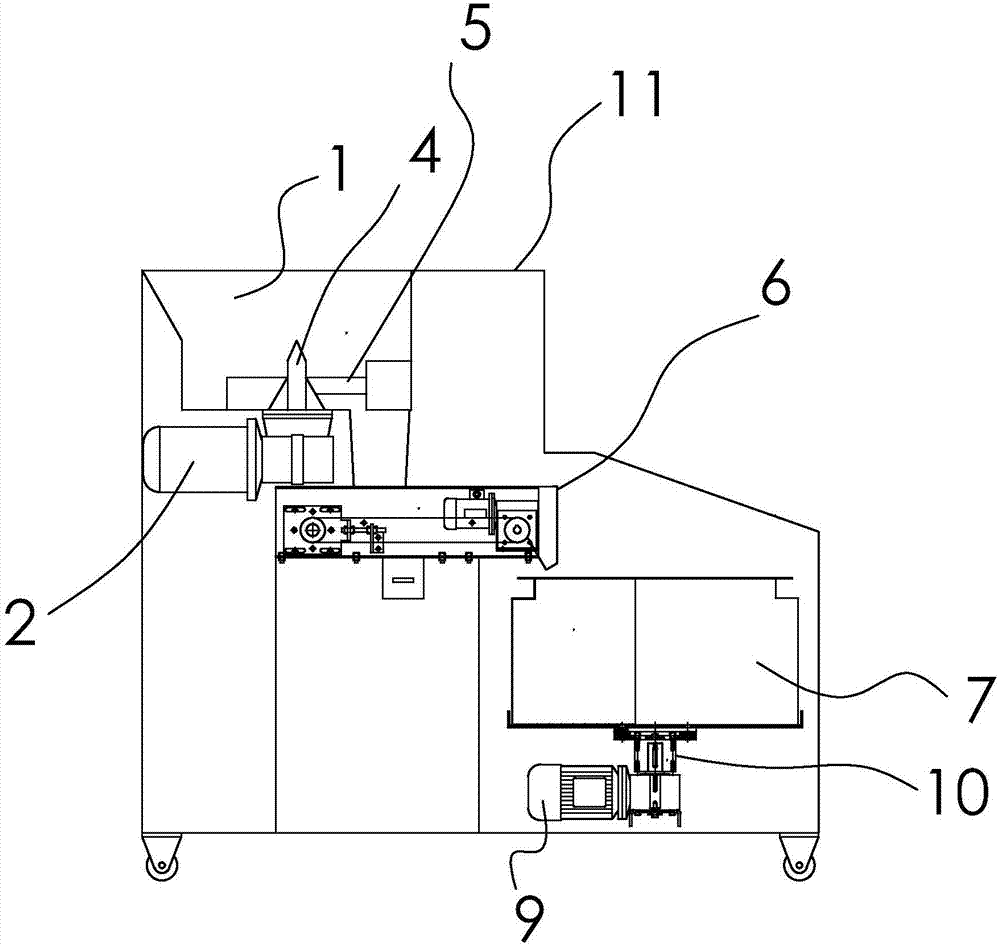

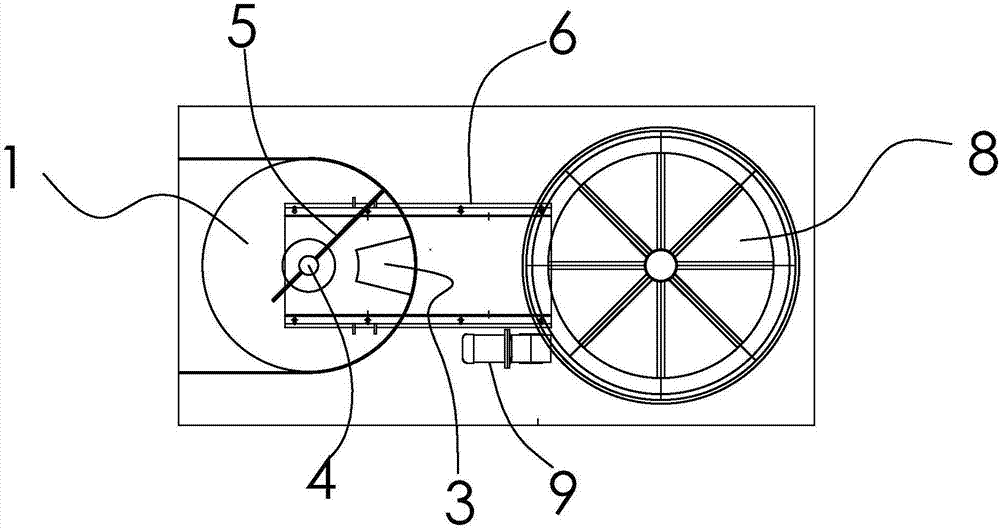

[0024] figure 1 and 2 Shown, a kind of stirring and mixing shrinkage device comprises:

[0025] A stirring mixer, the mixer is made up of a stirring and mixing straight barrel 1 and a first motor 2 located below the straight barrel 1; the bottom surface of the straight barrel 1 is provided with a discharge port 3, and the discharge port 3. It is arranged at one side of the center of the bottom surface of the straight barrel 1; the stirring and mixing straight barrel 1 is provided with an agitator, and the agitator is composed of a stirring shaft that passes through the center of the straight barrel 1 and is connected to the first motor 2. 4 and a stirring blade 5 arranged inside the straight barrel 1 and vertically connected to the stirring shaft 4.

[0026] Compared with the cone barrel, the straight barrel 1 can increase the volume; the first motor 2 is arranged under the straight barrel 1, and the overall installation and operation are more stable.

[0027] A small belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com