System and method for testing fractal seepage in single fracture by 3D printing under multiple testing condition coupling effect

A 3D printing, single-fissure technology, applied in the field of geotechnical engineering, can solve the problems of not being able to simply and quickly adjust the fractal dimension of rough fissures, the pressure and water head of fissure width, and achieve a simple structure, easy to analyze experimental data, and good experimental results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

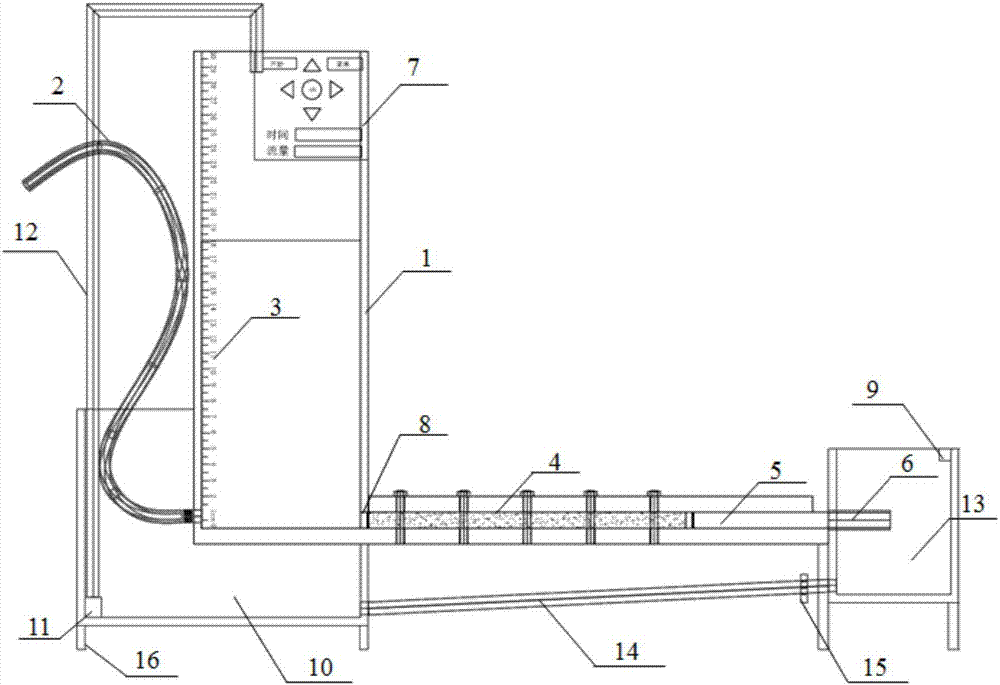

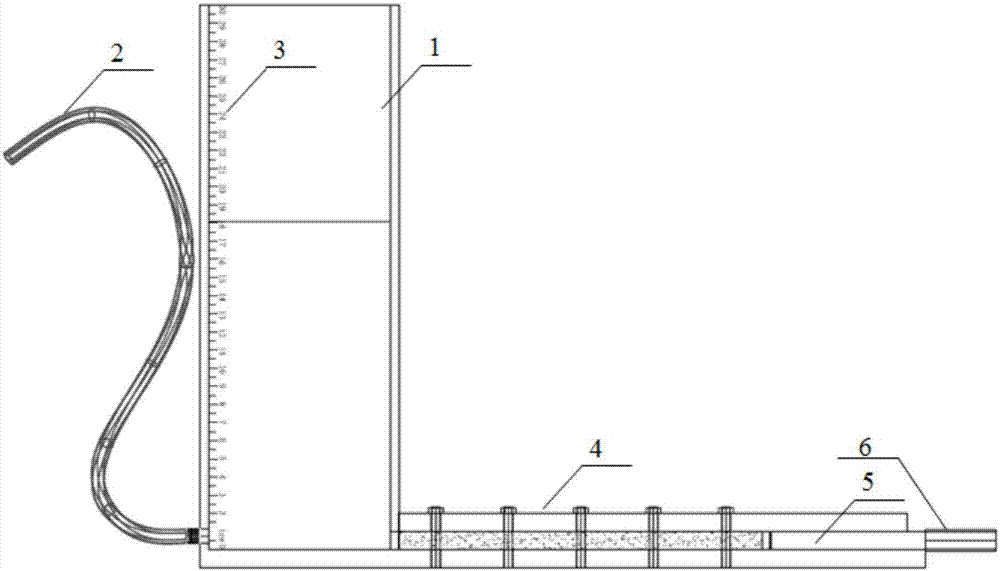

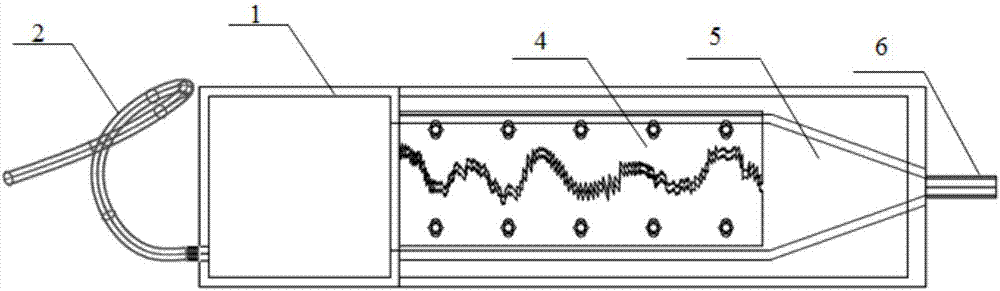

[0028] Such as Figure 1-3 As shown, the experimental system of the present invention includes a water head device, an experimental main device, an electronic monitoring device and a circulation device. The water head device includes a water storage tank 1, the side wall of the water storage tank 1 is vertically provided with a scale 3 for observing and recording the water level, and one end of the water level regulator 2 is connected to the bottom of the side wall of the water storage tank 1, and the water level inside the water tank is adjusted based on the principle of a connector . The water level regulator 2 can adopt a common transparent plastic circular tube, and its diameter can be selected flexibly. Considering that it is convenient for laboratory operation, it is preferably 10mm. The bottom or bottom of the side wall of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com