Test device and test method of critical current of superconductive wires under mixed stress

A technology of superconducting wire and critical current, which is applied in superconducting performance measurement, magnetic performance measurement, etc., can solve the problems that the critical performance of superconducting wire cannot be tested, and the design and maintenance of superconducting equipment cannot provide accurate and reliable experimental data. To achieve the effect of designing and manufacturing accurate and reliable experimental basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

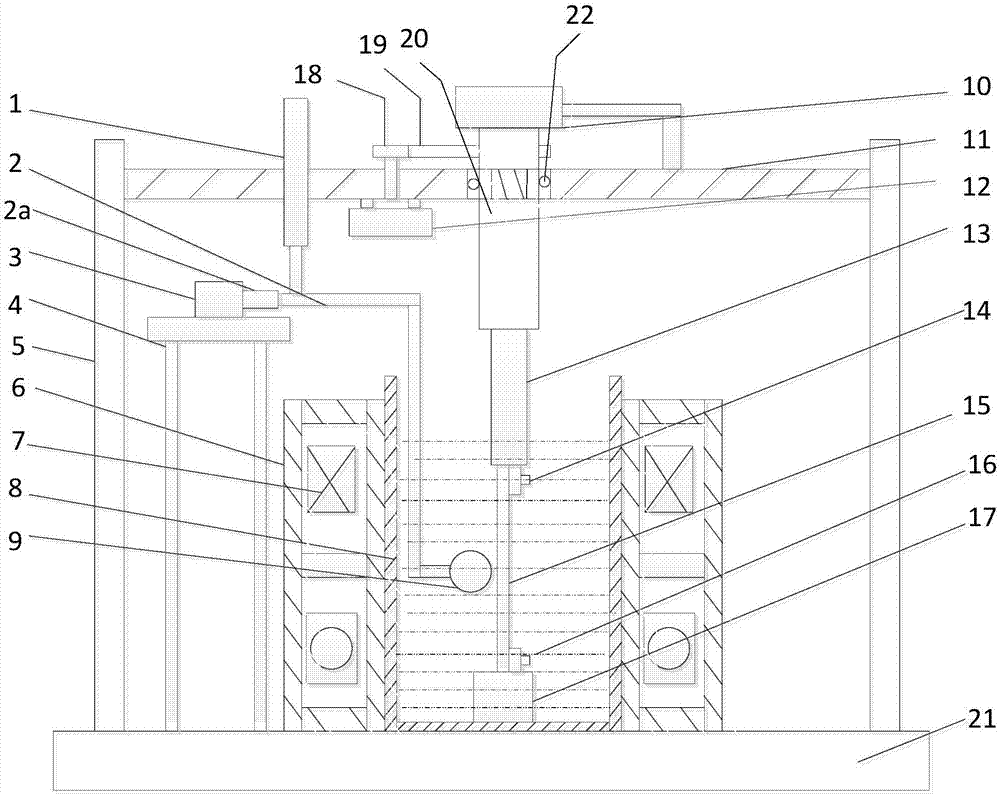

[0025] figure 1 It is shown that a specific embodiment of the present invention is a superconducting wire critical current testing device under mixed stress, which consists of:

[0026] A square Dewar 8 is placed on the bottom plate 21, and the left and right sides of the Dewar 8 are fixed with electromagnet shells 6, and the excitation coil 7 is installed in the inner cavity of the electromagnet shell 6;

[0027] Four columns 5 are fixed on the base plate 21, and the top plate 11 is fixed on the top of the four columns 5; the output shaft housing 20 is installed on the top plate 11 through the bearing 22 and passes through the top plate 11; the main shaft of the motor 12 is connected with the main gear 18, The main gear 18 meshes with the fixed gear ring 19 on the peripheral surface of the output shaft housing 20;

[0028] The top of the output shaft housing 20 fixes the vertical servo motor 10, and the output shaft 13 of the vertical servo motor 10 passes through the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com