Method for calculating working performance of static-pressure sliding seats on basis of fluid-solid coupling effect

A technology of working performance and calculation method, which is applied in the direction of calculation, design optimization/simulation, special data processing application, etc., and can solve problems such as sliding seat deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

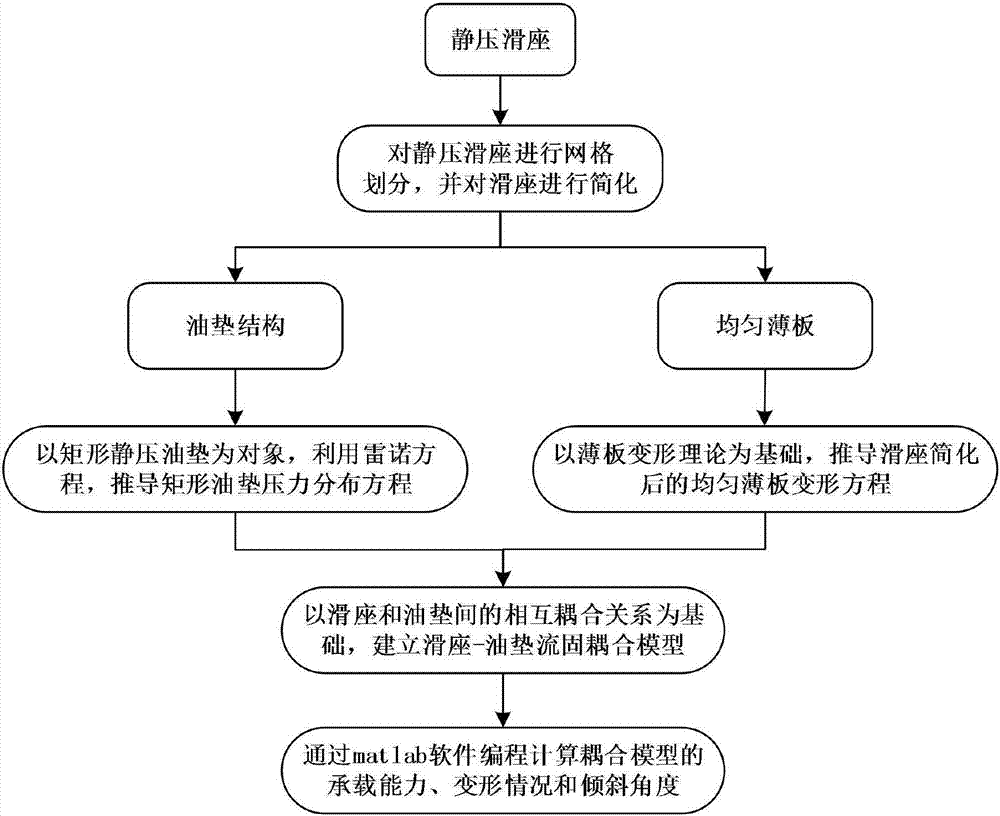

[0023] Such as figure 1 As shown, a calculation method based on fluid-solid coupling analysis for the hydrostatic slide seat of a heavy-duty gantry machine tool includes the following steps:

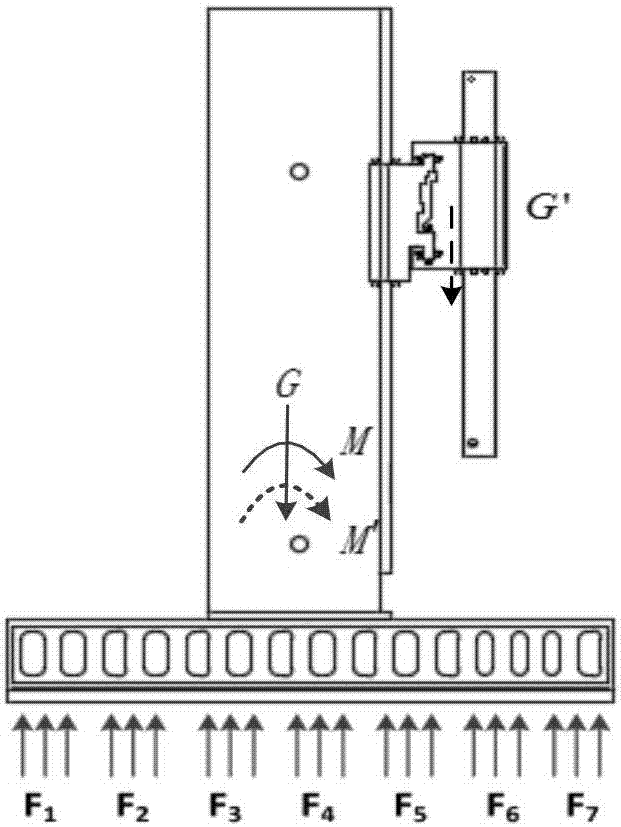

[0024] 1. According to the actual force situation of the static pressure slide seat, the force analysis of the static pressure slide seat is carried out, and the force analysis diagram of the static pressure slide seat is obtained (such as figure 2 ).

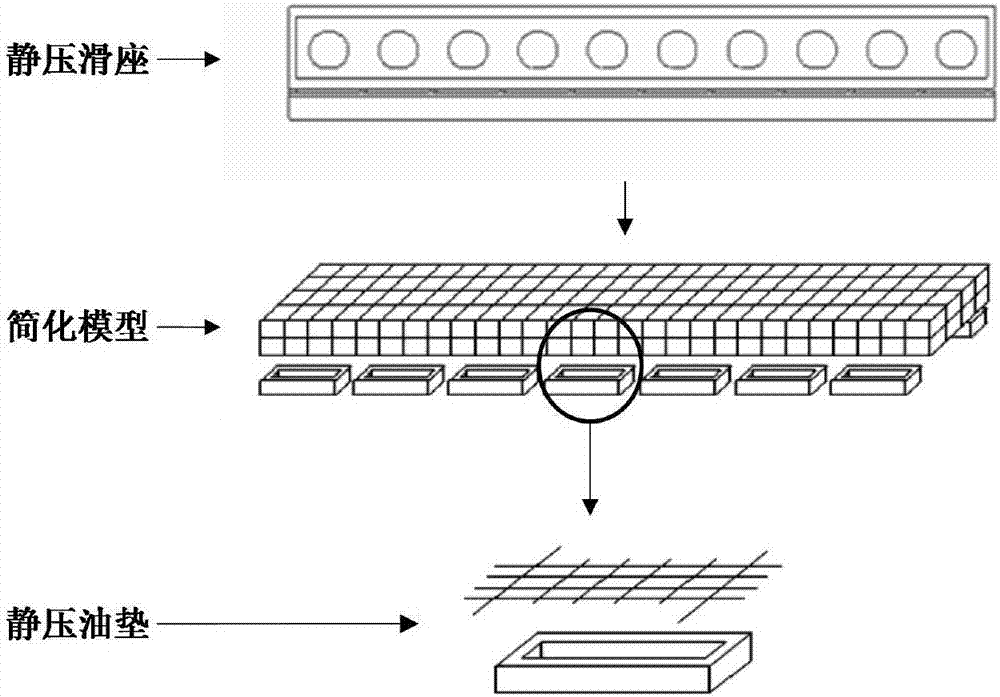

[0025] 2. According to the grid division method of finite element analysis, the sliding seat is meshed. The length of the upper side of the sliding seat in the X direction is a, the length of the upper side in the Y direction is b, and the corresponding coordinates are x and y respectively. According to the actual position of the oil pad on the sliding seat, the grid nodes of the sliding seat are determined. Simplify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com