Fluorescent glass-ceramic for high-power lighting and display, preparation method and application thereof

A fluorescent glass and high-power technology, which is applied in the field of high-power lighting and fluorescent glass ceramics for display and its preparation, can solve the problems of limiting the application of all-inorganic light conversion materials, not suitable for large-scale production, and complicated preparation processes, and achieve mechanical And the effects of stable physical and chemical properties, no permeation loss, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

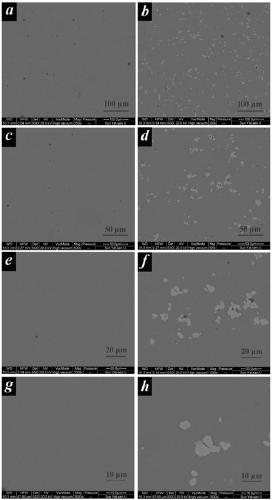

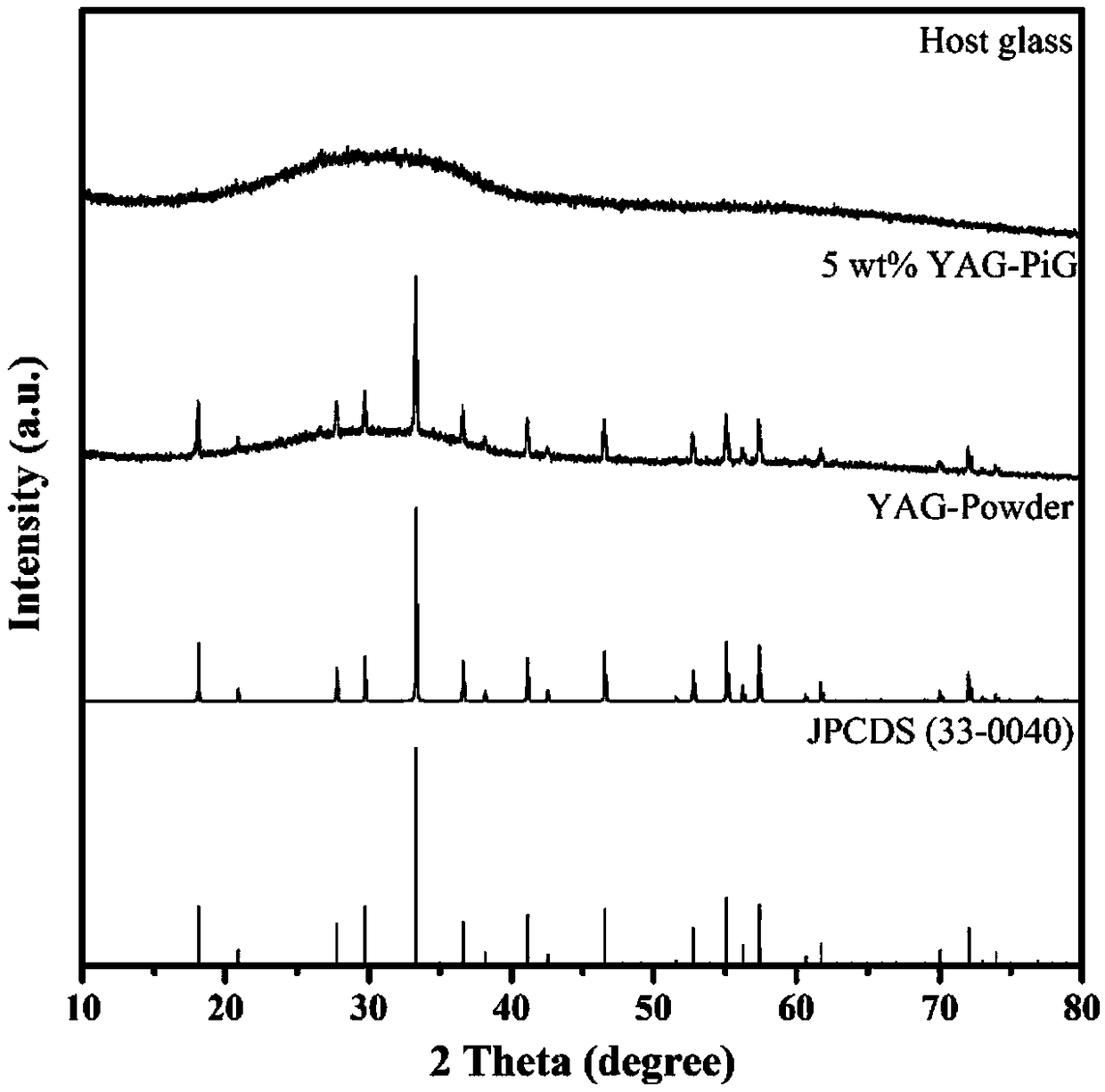

[0034] Glass matrix 55SiO 2 -10A 2 O-20ZnO-15MO Synthesis Technology and YAG:Ce 3+ - Preparation of PiG fluorescent glass ceramics

[0035] Table 1: The raw material composition of embodiment 1 glass matrix

[0036] raw material

[0037] Accurately weigh and analyze pure silicon dioxide (SiO2) according to Table 1 2 ), sodium carbonate (Na 2 CO 3 ), zinc oxide (ZnO), calcium carbonate (CaCO 3 ). The accurately weighed raw materials are ground by a ball mill for 6-8 hours, then poured into an alumina crucible, and then melted in a box furnace at 1350 °C for 1 hour, pour the molten glass liquid into distilled water to cool, dry and grind into pink. According to phosphor YAG:Ce 3+ (commercially available, its composition is Y 3 al 5 o 12 : Ce 3+ ) and glass powder with a mass fraction of 5:95, accurately weighed, ground in an agate mortar for 0.5 h, selected rubber molds of different sizes, and pressed the mixed powder into tablets by a cold isostatic table...

Embodiment 2

[0038] Example 2: Glass matrix 55SiO 2 -8A 2 O-20ZnO-22MO Synthesis Technology and YAG:Ce3+ - Preparation of PiG fluorescent glass ceramics

[0039] The raw material composition of table 2 embodiment 2 glass matrix

[0040] raw material

[0041] Accurately weigh and analyze pure silicon dioxide (SiO2) according to Table 2 2 ), sodium carbonate (Na 2 CO 3 ), zinc oxide (ZnO), calcium oxide (CaO). The accurately weighed raw materials are ground by a ball mill for 10-12 hours, poured into an alumina crucible, and then melted in a box furnace at 1400°C for 1.5 hours, poured molten glass into distilled water to cool, dried and ground into pink. According to the mass fraction of fluorescent powder and glass powder is 7:93, after accurate weighing, grind in an agate mortar for 0.5 h, choose rubber molds of different sizes, and compress the mixed powder through a cold isostatic tablet press (The pressing condition is 10 MPa for 30 minutes), and keep it in a box furnac...

Embodiment 3

[0042] Example 3: Glass matrix 55SiO 2 -10A 2 O-23ZnO-12MO Synthesis Technology and YAG:Ce 3+ - Preparation of PiG fluorescent glass ceramics

[0043] Table 3 The raw material composition of embodiment 3 glass matrix

[0044] raw material

[0045] Accurately weigh and analyze pure silicon dioxide (SiO2) according to Table 3 2 ), lithium carbonate (Li 2 CO 3 ), zinc oxide (ZnO), calcium carbonate (CaCO 3 ). The accurately weighed raw materials are ground by a ball mill for 6-8 hours, poured into an alumina crucible, and then melted in a box furnace at 1350°C for 1.5 hours, poured molten glass into distilled water to cool, dried and ground into pink. According to the mass fraction of phosphor powder and glass powder is 6:94, after accurate weighing, grind in an agate mortar for 0.5 h, choose rubber molds of different sizes, and compress the mixed powder through a cold isostatic tablet press (The pressing condition is 30 MPa for 10 minutes), and keep it in a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com