Environmentally friendly stiffening resin and preparation method thereof

A stiff resin, environmental protection technology, applied in the field of environmentally friendly stiff resin and its preparation, can solve the problems of formaldehyde, affect the physical and mental health of producers and users, and pollute the ecological environment, so as to prevent the growth of mold, improve heat resistance, and reduce the price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

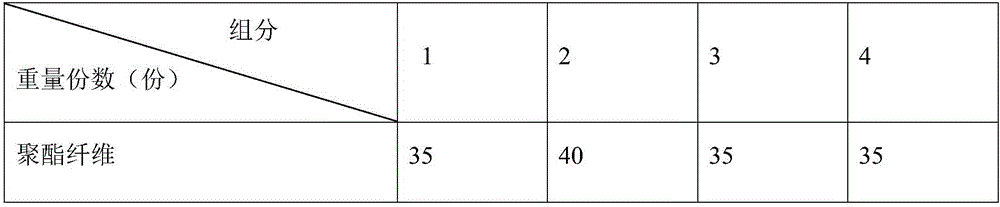

[0035] Embodiment 1-4: a kind of environmental protection rigid resin, comprises the component of each parts by weight shown in table 1, all the rest is alkaline water; A kind of method adopting above-mentioned components to prepare environmental protection rigid resin, and through the following steps be made of:

[0036] Step a, first add the formula amount of alkaline water into the reaction kettle, start stirring, the stirring speed is 80r / min and the temperature is raised to 80°C to obtain liquid a;

[0037] Step b, adding a formulated amount of polyester fiber to the liquid a obtained in step a, and continuing to heat up to 90°C to obtain liquid b;

[0038] Step c, adding a formula amount of ethanol to the liquid b obtained in step b, raising the temperature to 120°C to completely dissolve the product to obtain liquid c;

[0039] In step d, the liquid c obtained in step c is incubated for 2 hours, and a formula amount of defoamer and bactericide is added respectively to ...

Embodiment 5-6

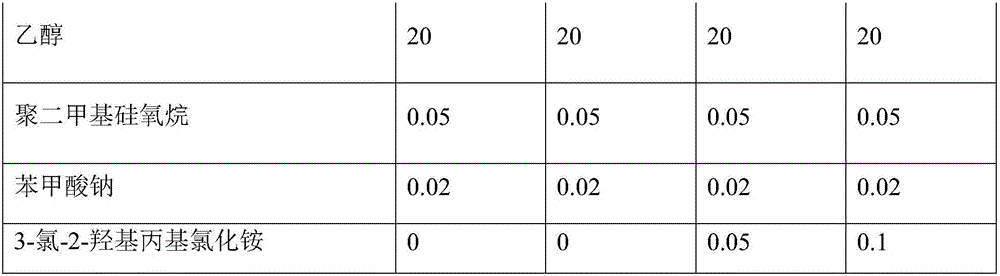

[0045] Embodiment 5-6: An environment-friendly stiff resin, the difference from Embodiment 4 is that the selected defoaming agent has different parts by weight, and the specific differences are shown in Table 2.

[0046] Table 2 each component of a kind of environment-friendly stiff resin and parts by weight thereof

[0047]

Embodiment 7-8

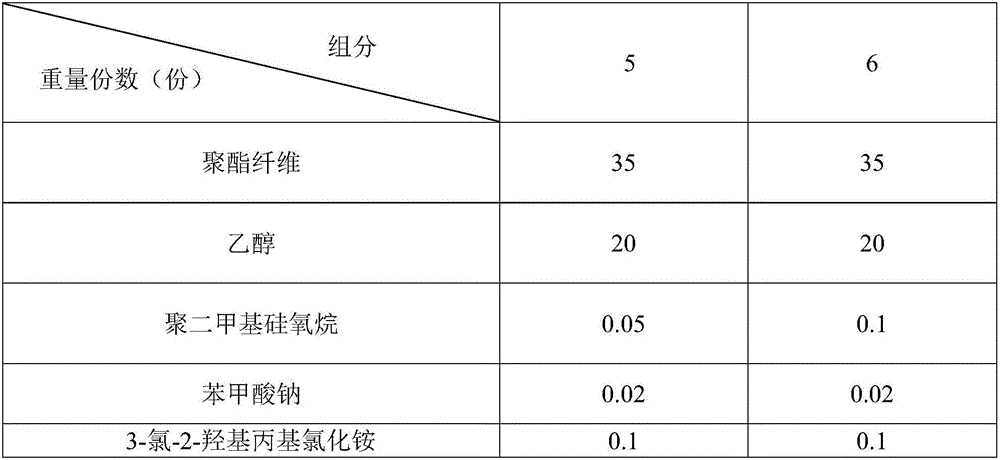

[0048] Embodiment 7-8: An environment-friendly stiff resin. The difference from Embodiment 4 is that the parts by weight of the selected fungicides are different, and the specific differences are shown in Table 3.

[0049] Table 3 A kind of environmental protection stiff resin component and parts by weight thereof

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com