Self-heating antibacterial artificial quartzite

An artificial quartz stone and self-heating technology, which is applied in the field of artificial stone production, can solve the problems of difficulty in satisfying diversification and uneven quality of artificial quartz stone, and achieve the effects of preventing mold growth, good bactericidal ability, and removing formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

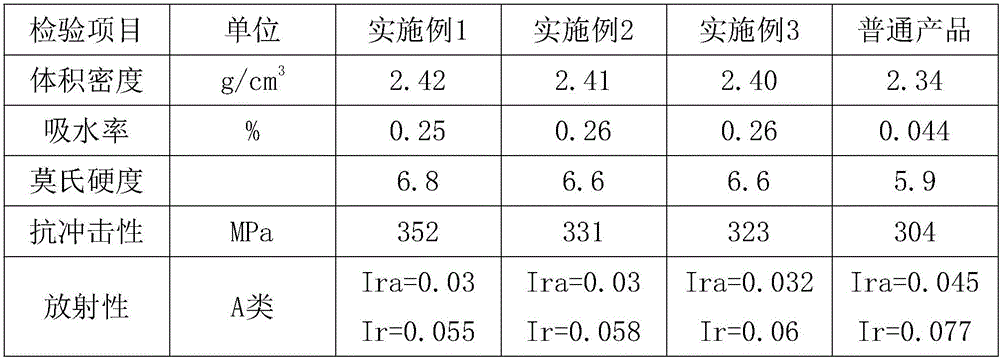

Examples

Embodiment 1

[0016] A self-heating antibacterial artificial quartz stone, made of the following components by weight (kg): 55 parts of 20-50 mesh quartz sand, 10 parts of 20-50 mesh carbon fiber powder, 10 parts of 20-50 mesh magnetic therapy fiber powder , 6 parts of 20-50 mesh tourmaline powder, 15 parts of nano-graphene, 15 parts of composite resin, 9 parts of accelerator, 16 parts of modified anti-aging agent, and 7 parts of colorant.

[0017] The composite resin is prepared by mixing phenolic resin, styrene modified alkyd resin, benzoin, phthalic acid polyester resin and tea polyphenol in equal parts.

[0018] The accelerator is at least one of vanadium phosphate, p-chlorobenzoic acid, N,N-dimethyl-p-methylaniline and triethylenediamine.

[0019] The modified anti-aging agent is prepared by mixing 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline and N-phenyl-β-naphthylamine in a ratio of 1:1.

[0020] A preparation process of self-heating antibacterial artificial quartz stone, comprisin...

Embodiment 2

[0025] A self-heating antibacterial artificial quartz stone, made of the following components by weight (kg): 52 parts of 20-50 mesh quartz sand, 8 parts of 20-50 mesh carbon fiber powder, 8 parts of 20-50 mesh magnetic therapy fiber powder , 4 parts of 20-50 mesh tourmaline powder, 12 parts of nano-graphene, 12 parts of composite resin, 8 parts of accelerator, 14 parts of modified anti-aging agent, and 6 parts of colorant.

[0026] The composite resin is prepared by mixing phenolic resin, styrene modified alkyd resin, benzoin, phthalic acid polyester resin and tea polyphenol in equal parts.

[0027] The accelerator is at least one of vanadium phosphate, p-chlorobenzoic acid, N,N-dimethyl-p-methylaniline and triethylenediamine.

[0028] The modified anti-aging agent is prepared by mixing 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline and N-phenyl-β-naphthylamine in a ratio of 1:1.

[0029] A preparation process of self-heating antibacterial artificial quartz stone, comprising ...

Embodiment 3

[0034] A self-heating antibacterial artificial quartz stone, made of the following components by weight (kg): 58 parts of 20-50 mesh quartz sand, 12 parts of 20-50 mesh carbon fiber powder, 12 parts of 20-50 mesh magnetic therapy fiber powder , 8 parts of 20-50 mesh tourmaline powder, 18 parts of nano-graphene, 18 parts of composite resin, 10 parts of accelerator, 18 parts of modified anti-aging agent, and 8 parts of colorant.

[0035] The composite resin is prepared by mixing phenolic resin, styrene modified alkyd resin, benzoin, phthalic acid polyester resin and tea polyphenol in equal parts.

[0036] The accelerator is at least one of vanadium phosphate, p-chlorobenzoic acid, N,N-dimethyl-p-methylaniline and triethylenediamine.

[0037] The modified anti-aging agent is prepared by mixing 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline and N-phenyl-β-naphthylamine in a ratio of 1:1.

[0038] A preparation process of self-heating antibacterial artificial quartz stone, comprisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com