Manufacturing method of active manganese wall cloth

A manufacturing method and active technology, applied in chemical instruments and methods, household walls, textiles and papermaking, etc., can solve secondary pollution and other problems, and achieve the effects of preventing mold growth, corrosion resistance and light resistance, and improving bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of manufacture method of active manganese wall cloth, comprises the steps:

[0041] (1) Jacquard layer weaving: Immerse the warp threads of the jacquard layer into the first active manganese mixture, take out and air-dry when the warp threads of the jacquard layer are soaked; immerse the weft threads of the jacquard layer into the photocatalyst mixture, take out after the weft threads of the jacquard layer are soaked Air-drying; interweaving the air-dried jacquard layer warp and air-dried jacquard layer weft warp and weft to form a jacquard layer.

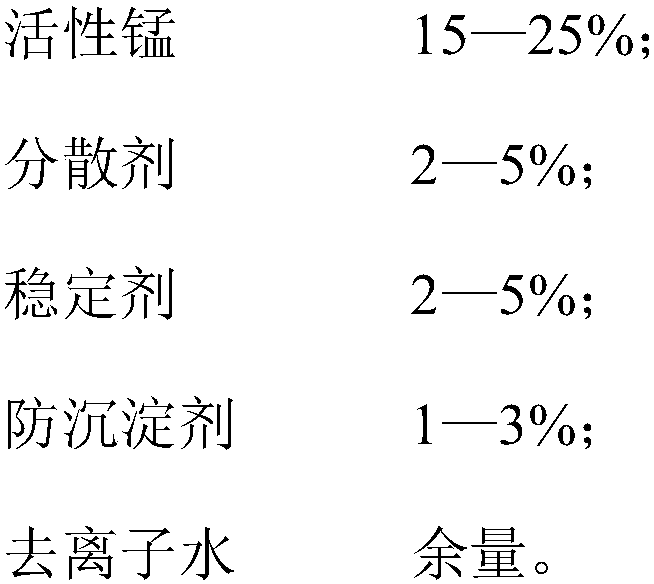

[0042] The first active manganese mixed solution is composed of the following components in mass percentage:

[0043]

[0044]

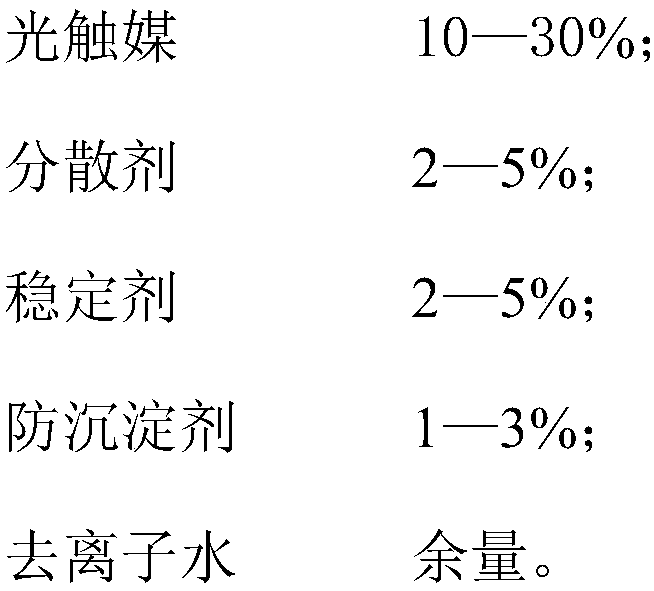

[0045] Photocatalyst mixed solution is made up of each component of following mass percentage:

[0046]

[0047] The warp thread of the jacquard layer is made by blending hemp fiber and silver fiber, and the weft thread of the jacquard layer is made by blending the special-shaped fib...

Embodiment 2

[0059] According to the manufacture method of embodiment 1 wall covering, the difference from embodiment 1 is that the first active manganese mixed solution is made of the following components in mass percentage:

[0060]

[0061]

[0062] Photocatalyst mixed solution is made up of each component of following mass percentage:

[0063]

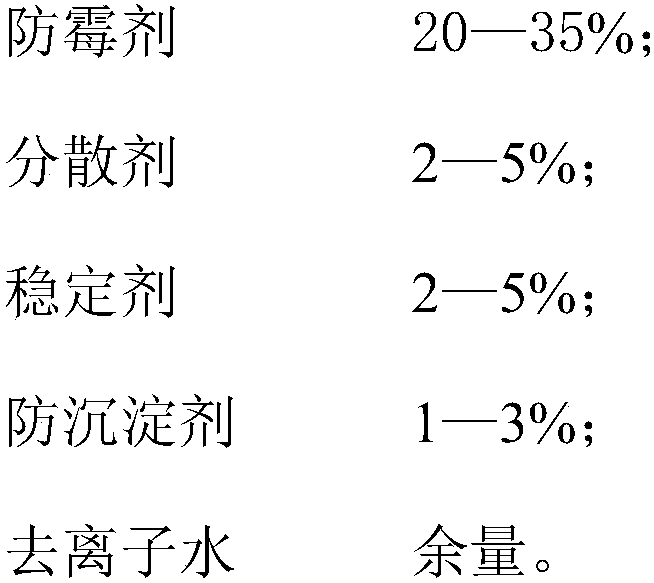

[0064] The antifungal agent mixture is composed of the following components in mass percentage:

[0065]

[0066] The second active manganese mixed solution is made of the following components in mass percentage:

[0067]

[0068] The composite glue is composed of the following components in mass percentage:

[0069]

[0070]

Embodiment 3

[0072] According to the manufacture method of embodiment 1 wall covering, the difference from embodiment 1 is that the first active manganese mixed solution is made of the following components in mass percentage:

[0073]

[0074] Photocatalyst mixed solution is made up of each component of following mass percentage:

[0075]

[0076] The antifungal agent mixture is composed of the following components in mass percentage:

[0077]

[0078]

[0079] The second active manganese mixed solution is made of the following components in mass percentage:

[0080]

[0081] The composite glue is composed of the following components in mass percentage:

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com