Pre-stress post-grouting variable-cross-section hollow pipe pile and construction method thereof

A construction method and variable-section technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as unoptimistic durability of reinforced concrete piles, inability to fully exert the frictional resistance of the pile body, and difficulty in exerting the bearing capacity of the pile tip. , to achieve the effect of eliminating adverse effects, reducing settlement and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with the accompanying drawings, the structure of the present invention will be further described.

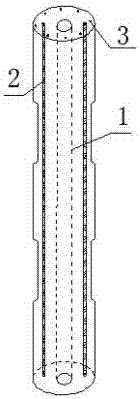

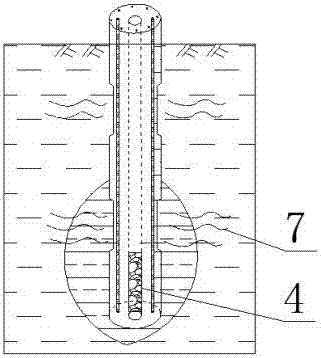

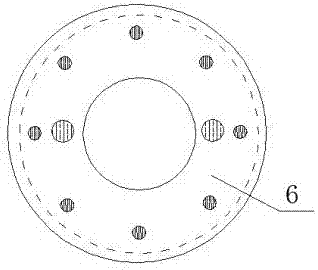

[0017] A hollow pipe pile with variable cross-section after grouting after prestressing is characterized in that: the pipe pile is a variable-section reinforced concrete pipe pile with a vertical through hole 1 in the center: the reinforcement cage of the reinforced concrete pipe pile is composed of eight One steel bar 3 and a plurality of stirrup bars 5 are formed, eight steel bars 3 are vertically fixed in multiple stirrup bars 5 aligned up and down, and the eight steel bars 3 are evenly distributed around the stirrup bars 5, and the steel bars and stirrup bars are fastened together In the concrete 6; two grouting pipes 2 deep to the bottom of the pile are evenly distributed in the concrete around the vertical through hole 1.

[0018] The prestressed grouting variable cross-section hollow pipe pile is a variable cross-section pipe pile with a height of 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com