Aluminum sectional bar Chinese-style frame assembling house

An aluminum profile, assembling room technology, applied in the direction of roof, roof, building components, etc., to achieve the effect of wide technical adaptability, convenient on-site construction, and fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

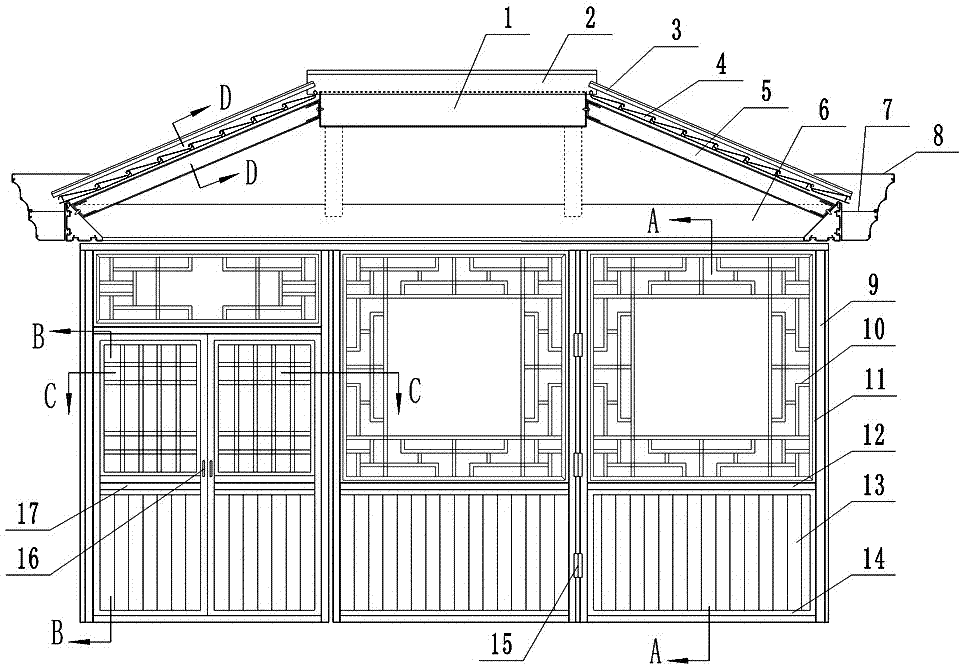

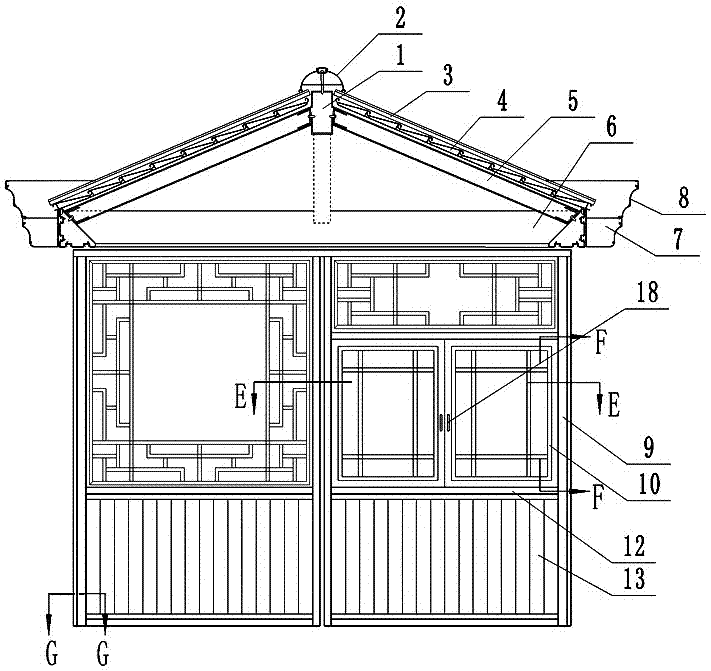

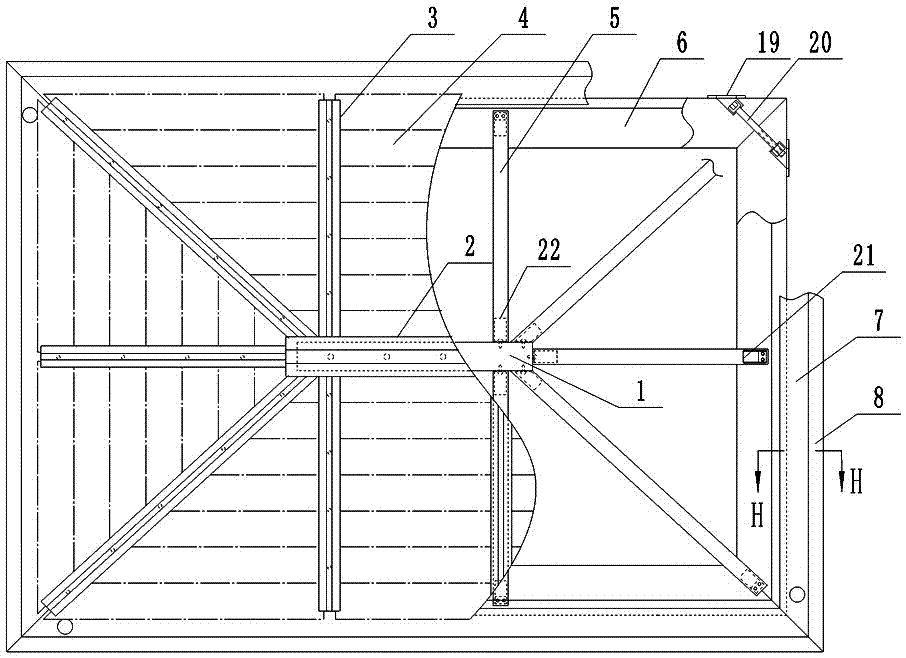

[0027] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, a Chinese-style frame assembled house with aluminum profiles is composed of a roof and side walls, rafters 5 are installed between the upper beam 1 and the lower beam 6 of the roof, roof tiles 4 are installed between the rafters 5, and the frame 9 of the side wall The inner lower part is installed with a gusset plate 13, the upper part is installed with a Chinese-style lattice railing 10, one side of the side wall is installed with a side-by-side door 16, and the other side is equipped with a side-by-side window 18, which constitutes the upper beam 1, rafters 5, and the frame of the side wall of the house. 9 and the Chinese-style grid column 10 are made of aluminum alloy square tube profiles, the lower beam 6 is a triangular aluminum alloy square tube profile, the roof tile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com