Evaporating pipe and spraying device

A spray device and evaporation tube technology, applied in the field of evaporation tubes, can solve the problems of poor uniformity of the oil mist field in the combustion chamber, and achieve the effects of avoiding adverse effects, uniform distribution of oil mist, and strengthening the degree of oil-gas premixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

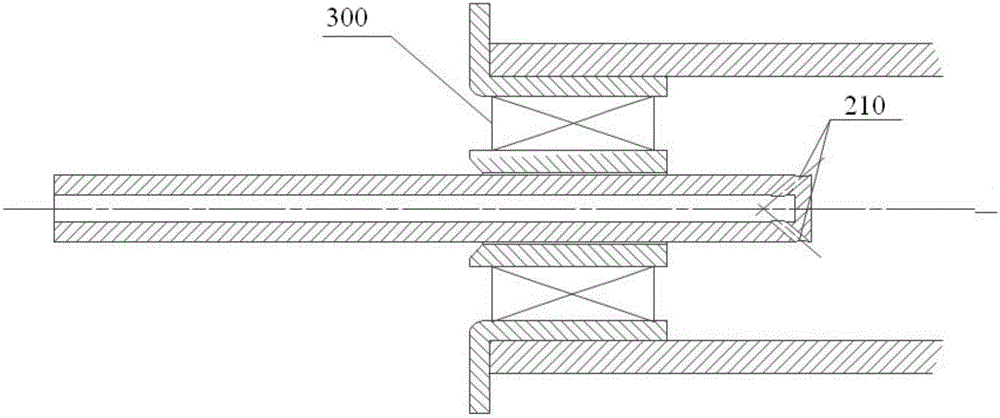

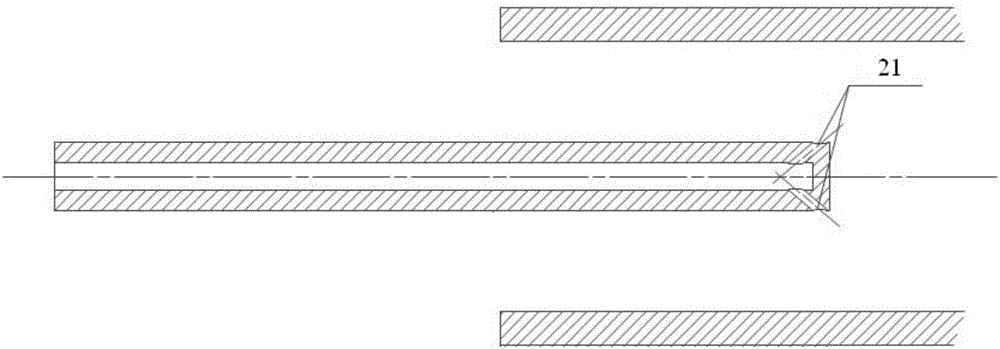

[0026] refer to image 3 and 4 , the preferred embodiment of the present invention provides an evaporator tube 100, the fuel nozzle 200 extends from the inlet end of the evaporator tube 100, and the feature is that the inlet end of the evaporator tube 100 is provided with a The air of the swirler 300 is converted into a swirling airflow swirler 300, the swirler 300 is set between the evaporation tube 100 and the fuel nozzle 200, and the swirler 300 is located in the behind the nozzle 210 of the fuel nozzle 200, so that the fuel sprayed from the nozzle and the swirling airflow form an atomized fuel-air mixture.

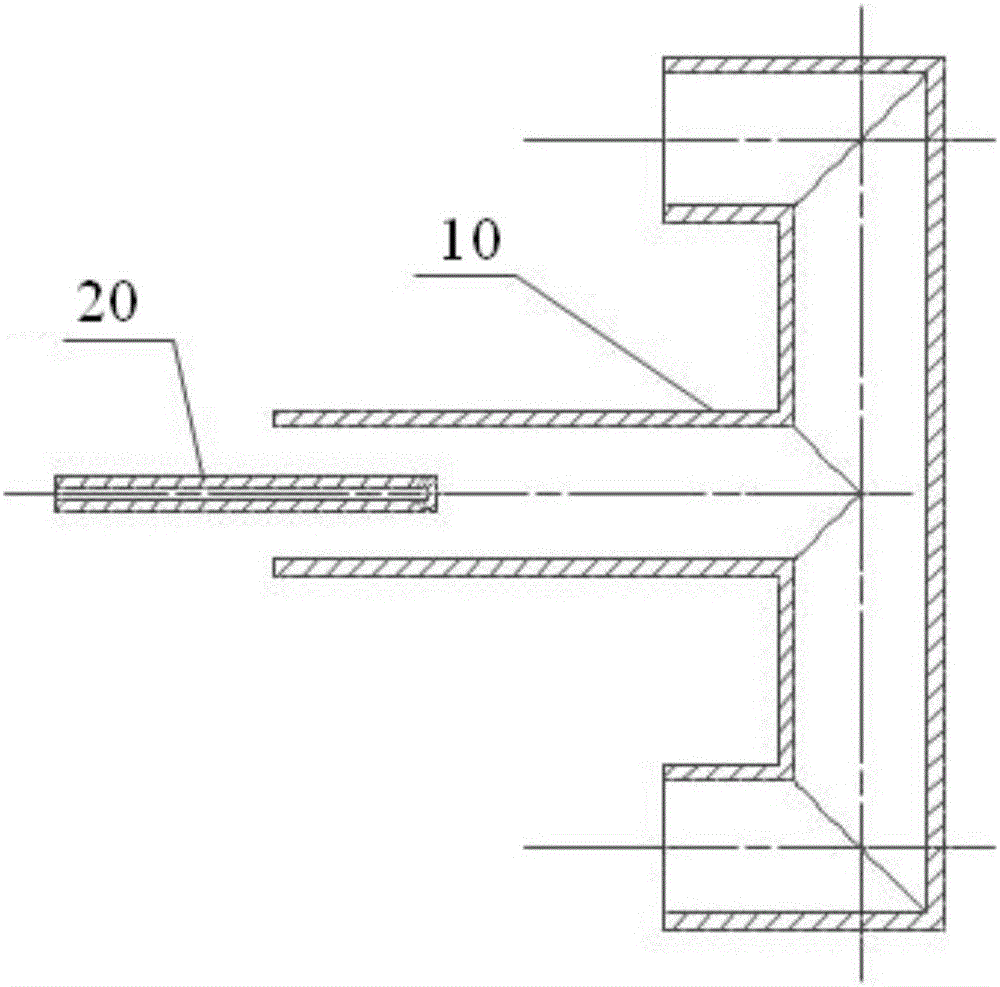

[0027] The inventors found that, with reference to figure 1 , 2 and 6, in the design of the conventional evaporator tube 10, the advers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com