Preparation method of super-hydrophobic surface with multi-scale structure

A super-hydrophobic, multi-scale technology, applied in the photolithographic process of the patterned surface, the process for producing decorative surface effects, microstructure technology, etc., can solve the problems of easy damage, loss of surface super-hydrophobicity, etc. Achieve the effect of prolonging service life, reducing processing cost and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

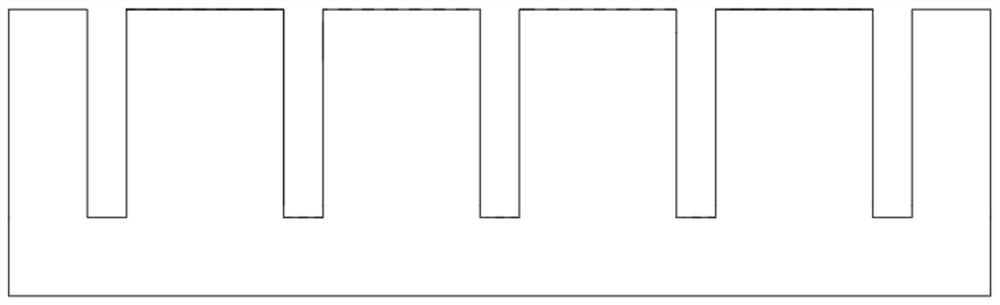

[0031] see Figure 1 to Figure 5 , a method for preparing a multi-scale structure super-hydrophobic performance surface, comprising the following steps:

[0032] Step 1, spin-coating a layer of positive photoresist on the silicon substrate, and exposing with a mask plate with a light-transmitting grid array;

[0033] Step 2, putting the structure obtained after exposure in step 1 into a developing solution for development to obtain a silicon wafer substrate with a grid-shaped raised photoresist array;

[0034] Step 3, processing the silicon wafer substrate obtained in step 2 in an oxygen plasma dry degumming machine to obtain a degummed and clean silicon wafer substrate;

[0035] Step 4, processing the silicon substrate obtained in step 3 by wet etching to obtain a silicon substrate with a grid-type protrusion array;

[0036] Step 5, treating the silicon wafer substrate obtained in step 4 with acetone, removing the surface photoresist layer, and using a PECVD system to depos...

Embodiment

[0048] Concrete implementation steps of the present invention are as follows:

[0049] 1) Spin-coat a layer of HDMS on the silicon wafer substrate first, the solution dosage is 1ml, then spin-coat a layer of AZP4620 photoresist with a thickness of 8 μm, and then use a mask plate with a grid light-transmitting array for exposure. Among them, the width of the light-transmitting area of the mask with a grid light-transmitting array is 10 μm, and the distance between two adjacent grids is 40 μm. The shape and pattern distribution of the mask are as follows: figure 1 As shown, the details of the graphics area are as follows figure 2 As shown, the shaded part is the light-transmitting region.

[0050] 2) Put the structure obtained after exposure in step 1) into a developing solution for development. After development, the area not exposed to light due to the mask plate remains, and the exposed part is washed away. Finally, a photoresist is obtained. A silicon wafer substrate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com