Grain selection system having function of distributing materials uniformly and pre-selecting

A material and grain technology, applied in the field of grain cleaning system, can solve the problems of large cleaning loss, inability to adapt to the cleaning of a large number of exudates, poor effect of uniform distribution of exudates in the cleaning system, etc., and achieve the effect of reducing the cleaning load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation process of a grain cleaning system with uniform distribution of materials and pre-cleaning functions of a specific model of the present invention will be further described below in conjunction with the accompanying drawings.

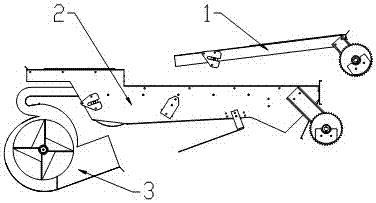

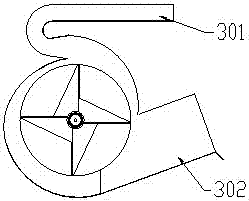

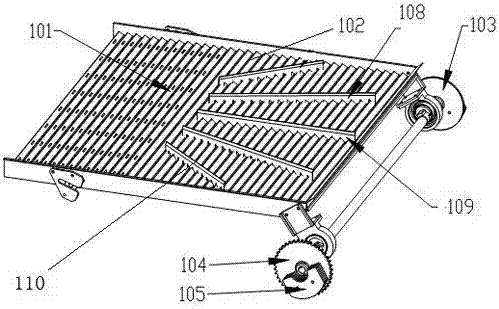

[0030] Such as figure 1 As shown, the grain cleaning system with uniform material distribution and pre-cleaning function of the present embodiment includes a material shaking plate 1, a cleaning screen 2 and a blower fan 3, such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the material shaking plate 1 is sequentially composed of a first shaking plate surface 101 and a second shaking plate surface 102, the first shaking plate surface 101 is stepped, and is formed by sequentially connecting inclined surfaces and planes, Wherein have elongated hole 106 on the inclined surface, have circular hole 107 on the plane, elongated hole 106 width is less than grain diameter, and the diameter of circular hole 107 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com