GMP workshop animal feeding room sewerage system process design

A technology of animal feeding and sewage system, which is applied in animal houses, poultry industry, poultry cages or houses, etc., can solve the problems of high viscosity, air leakage in sewage pipe room, and difficult discharge, so as to avoid Blocking, ensuring tightness, and ensuring the effect of liquid seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

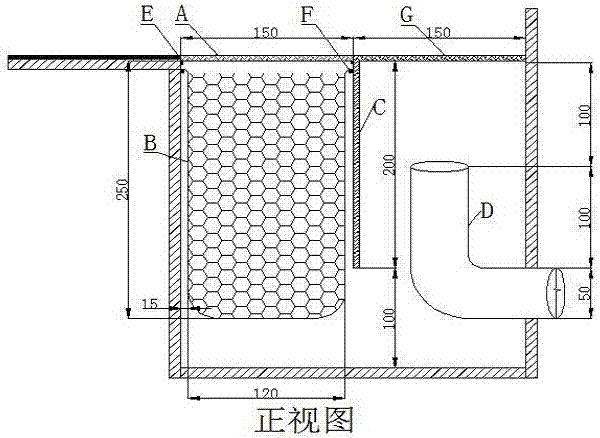

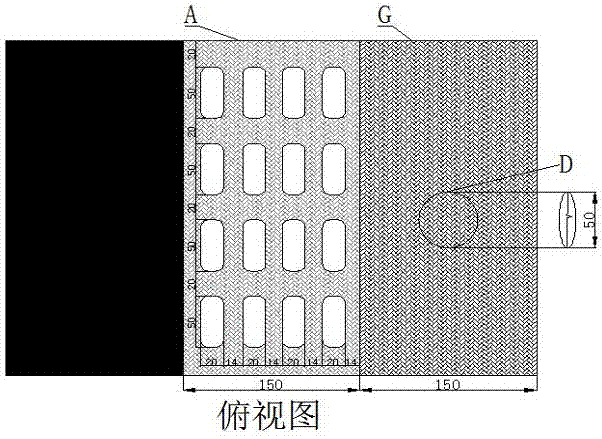

[0026] Operating mode:

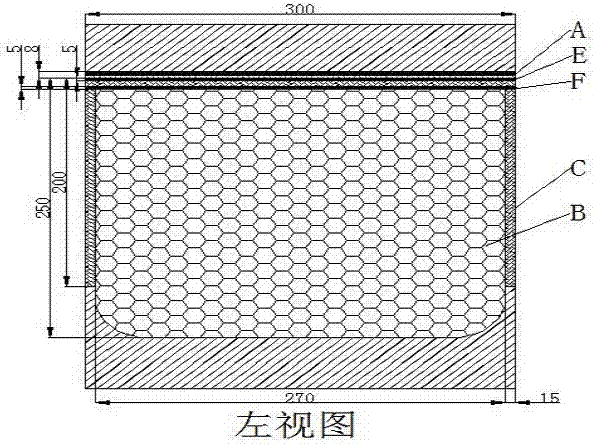

[0027] 1. The dirt in the animal breeding room flows into A through cleaning methods;

[0028] 2. The dirt passes through B for solid-liquid separation, and the liquid flows into the partition area of D through C;

[0029] 3. The liquid level in the sewage system is always higher than the lowest end of C, and when the liquid level is higher than the upper surface of D, the sewage is discharged;

[0030] 4. When the liquid level in the sewage system is discharged to the upper surface lower than D, stop the sewage and repeat the above steps;

[0031] Cleaning mode:

[0032] 1. Ensure that the liquid level in the sewage tank is always higher than the lowest end of C;

[0033] 2. Manually lift A, lift B out of the sewage tank, and remove the trapped dirt in B;

[0034] 3. Clean up the intercepted matter in B and put it back into the sewage system after cleaning, and reset A to enter the operation mode;

[0035] Maintenance mode:

[0036] 1. Clean t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com