Process for manufacturing fusible interlining and fusible interlining thus obtained

A lining and melting point technology, which is used in the field of manufacturing fusible linings, which can solve the problems of uneven layers and inaccurate powder quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

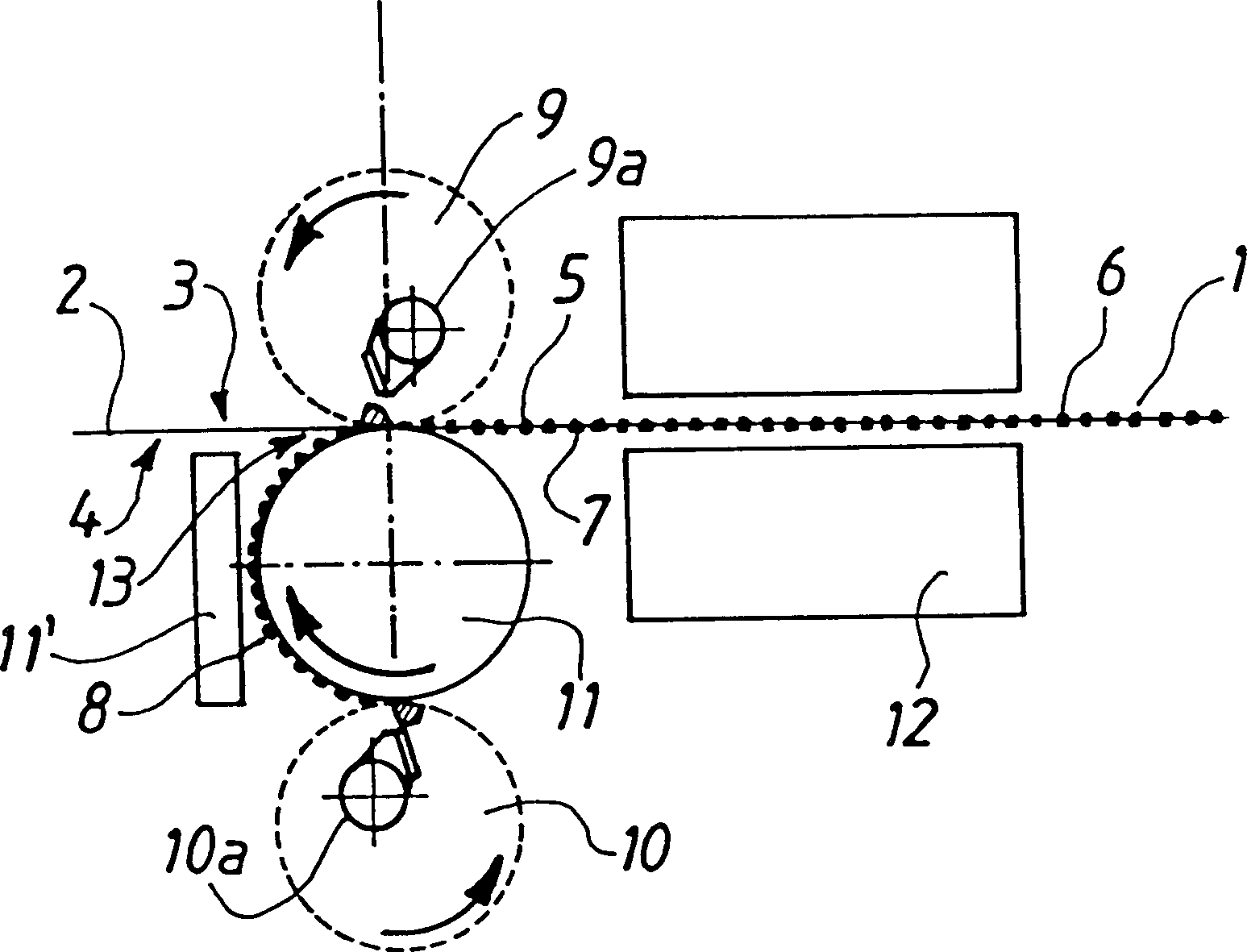

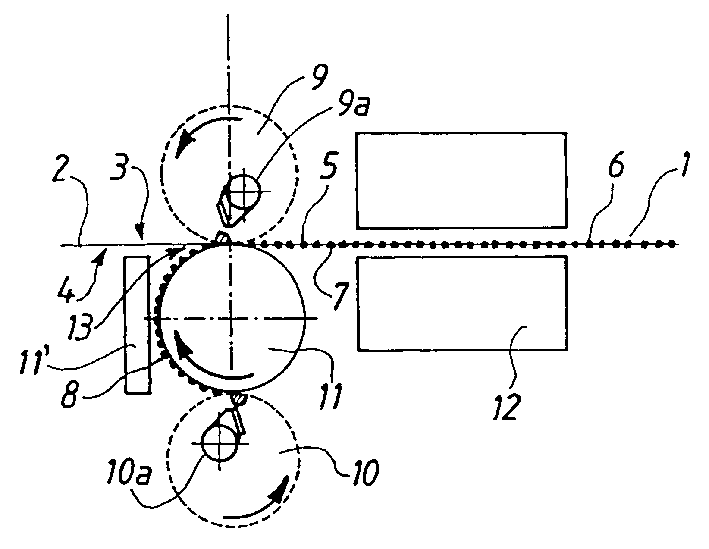

[0032] The fusible liner 1 according to the invention comprises a base fabric 2 covered on each of its surfaces 3,4 with a layer 5,7 of a heat-fusible polymer.

[0033] The base fabric 2 is known per se. Its properties are the same as those of conventionally manufactured linings in the field of linings.

[0034] It can be a woven, knitted or nonwoven fabric. Often these fabrics are denatured and then polished before being used as a base cover.

[0035] The base fabric 2 comprises a heat-fusible first layer 5 attached to the front side 3 of the base fabric 2 and a second layer 7 attached to the back side 4 of the base fabric 2 . The first layer 5 is heat-fusible, while the melting point of the second layer 7 is higher than that of the first layer 5 . The term "hot melt" refers to a layer that can be used for thermal bonding, which is solid at ambient temperature and has no adhesive ability; Adhesiveness. Thus, the thermoplastic flow of the first layer 5 is better than that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com