A large deep-water net cage adopting a longitudinal skeleton-type main frame

A longitudinal skeleton type, deep-water cage technology, applied in application, climate change adaptation, fish farming, etc., to achieve the effects of firm and reasonable structure, reduced vibration amplitude, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] As a preferred embodiment of the present invention: in the case of no external force acting on the large deep-water net cage, the height of the upper floating frame immersed in seawater accounts for 1 / 2 to 3 / 5 of its total height.

[0039] In order to facilitate the adjustment of the buoyancy of the upper floating frame and the lower floating frame, and in order to cooperate with the existing deep-water cage floating frame construction process, to reduce the construction difficulty and construction cost of the longitudinal frame type main frame, as a preferred embodiment of the present invention:

[0040] The upper floating frame includes at least one upper floating tube frame 1 arranged horizontally, and for the case of including more than two upper floating tube frames 1, each upper floating tube frame 1 is progressively increased according to the horizontal cross-sectional area of the enclosed space Sorting, then the former upper floating tube frame 1 is located in ...

Embodiment 1

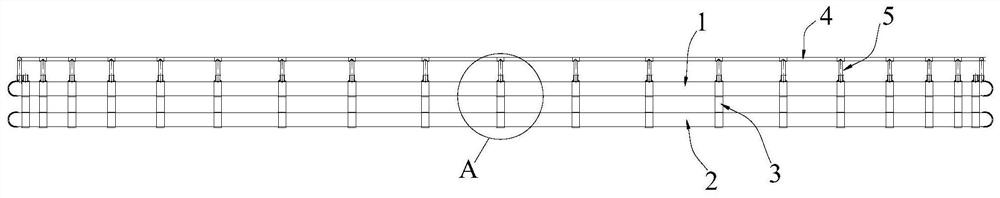

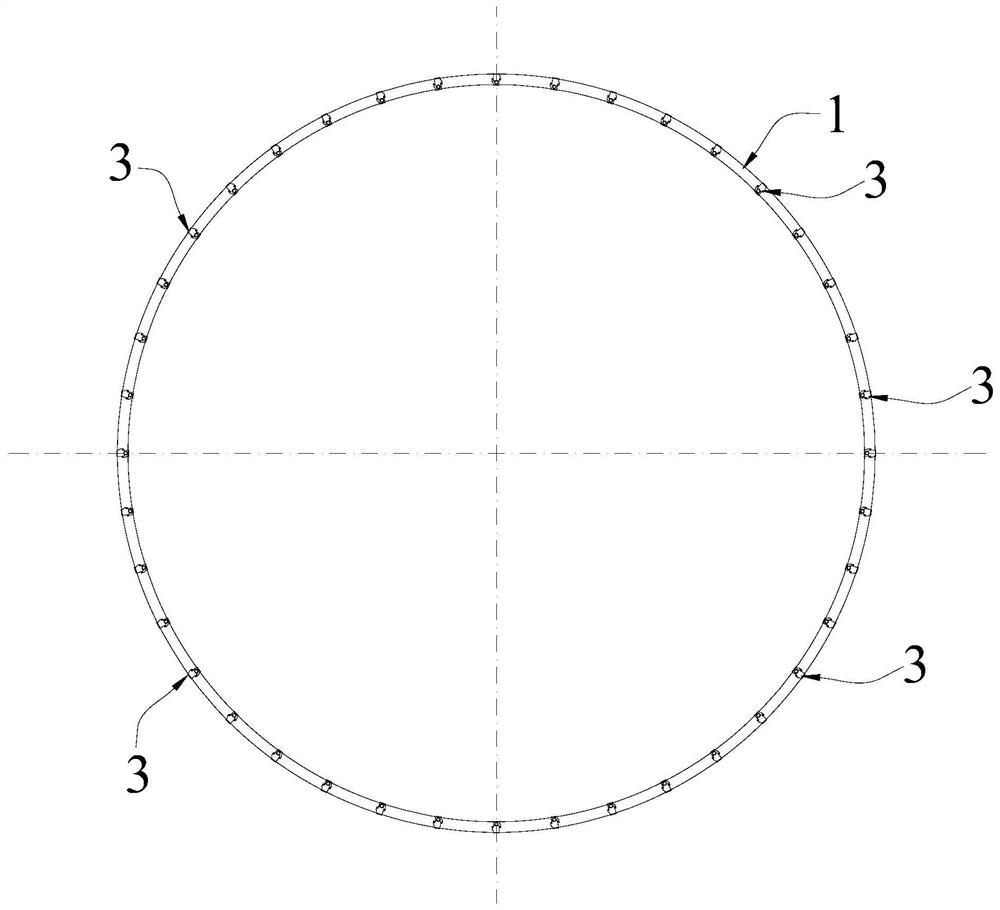

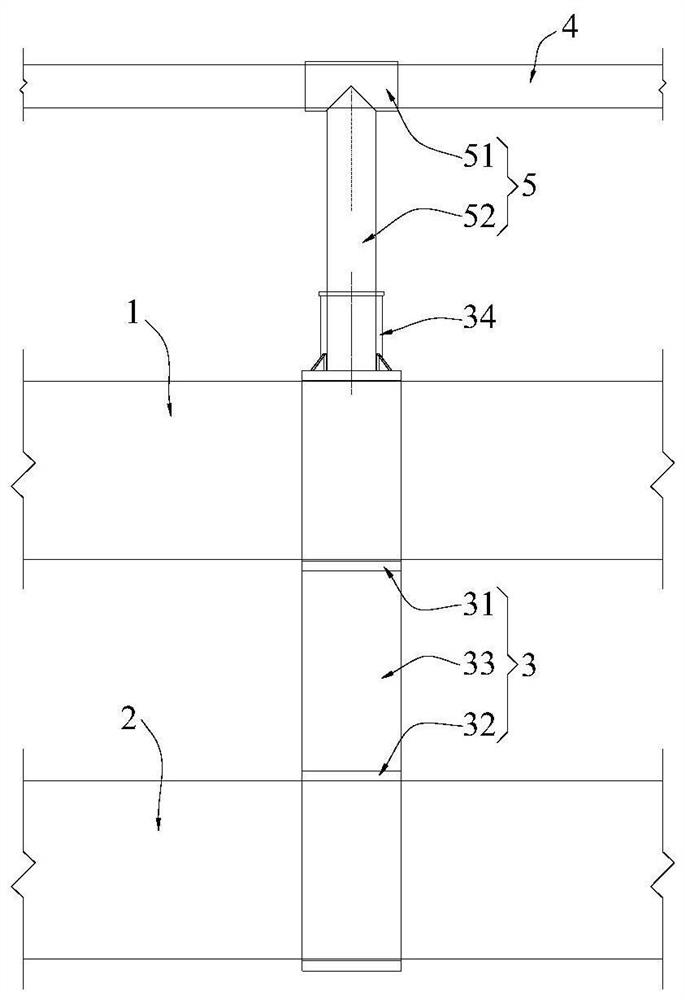

[0045] Such as Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention is based on the above-mentioned inventive concepts, and adopts the following specific solutions:

[0046] The upper floating frame includes an upper floating tube frame 1, and the lower floating frame includes a lower floating tube frame 2; the I-shaped frame 3 is correspondingly provided with an upper casing 31 and a lower casing 32 arranged in parallel. The connecting frame 33 of the word frame 3 is a plate connected between the upper casing 31 and the lower casing 32 .

[0047] The above-mentioned inventive concept is specifically described below by four examples:

Embodiment 2

[0049] Such as Figure 5 to Figure 7 As shown, the second embodiment of the present invention is based on the above-mentioned inventive concepts, and adopts the following specific solutions:

[0050] The upper floating frame includes two upper floating tube frames 1, and the lower floating frame includes two lower floating tube frames 2; the I-shaped frame 3 is correspondingly provided with two upper casings 31 and two lower casings 32 arranged in parallel , the connecting frame 33 of the I-shaped frame 3 is provided with five flow pipes 331 for the passage of water, and is provided with two upper casings 31, two lower casings 32, and five flow pipes 331 connected into one. A connecting plate 332, wherein five flow pipes 331 are parallel to the upper casing 31 and the lower casing 32, the first flow pipe 331 is located between the two upper casings 31, and the second flow pipe 331 is located between the two upper casings 31. Between the lower casings 32, the third flow pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com