Electromagnetic combination linear vibration type mixed particle sorting device

A linear vibration and sorting device technology, applied in solid separation, chemical instruments and methods, grids, etc., can solve the problems of high mechanical mechanism and structure requirements, achieve good sorting effect, strengthen sorting effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

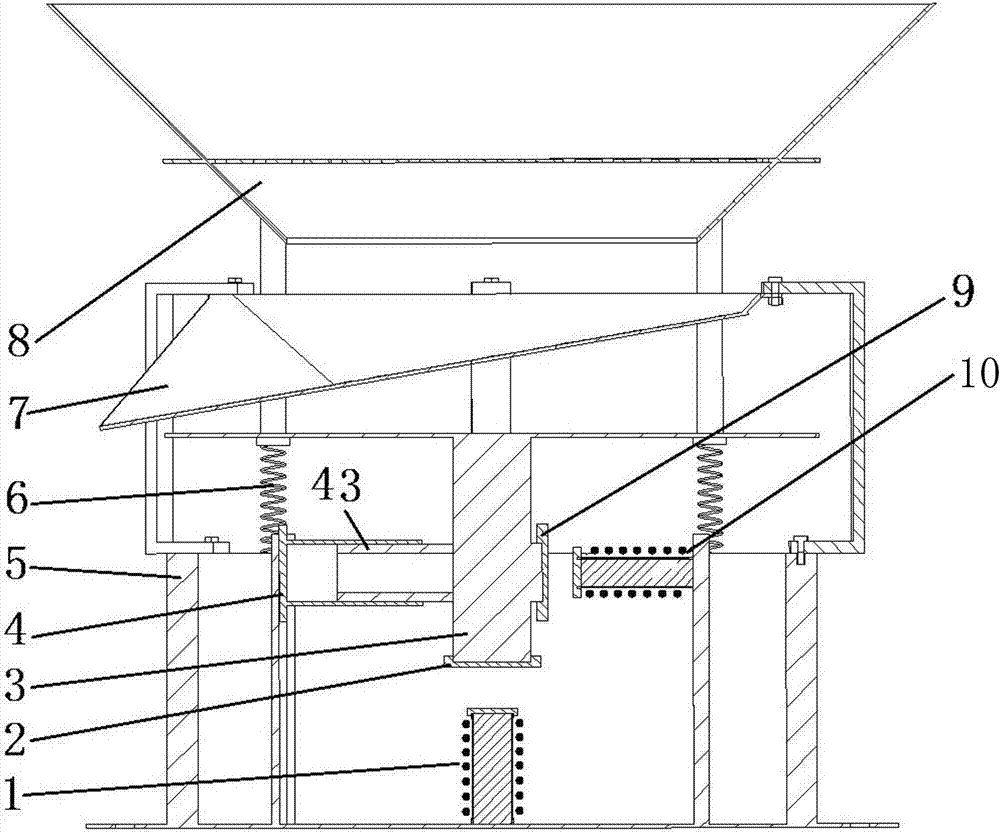

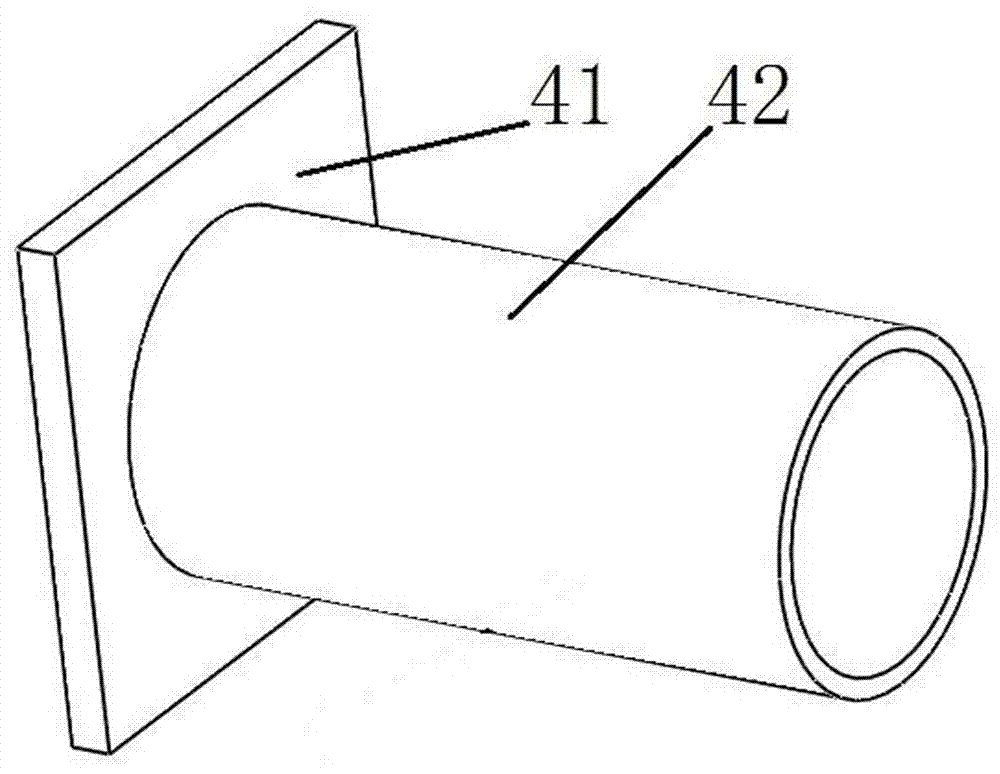

[0024] like figure 1 , 2 , 3, 4 and 5, the electromagnetic combination linear vibration type mixed particle sorting device of the present invention is characterized in that it includes a vibration generating mechanism and a vibration groove 8 arranged above the vibration generating mechanism, which is connected to the bottom of the vibration groove 8 The connection pad 7,

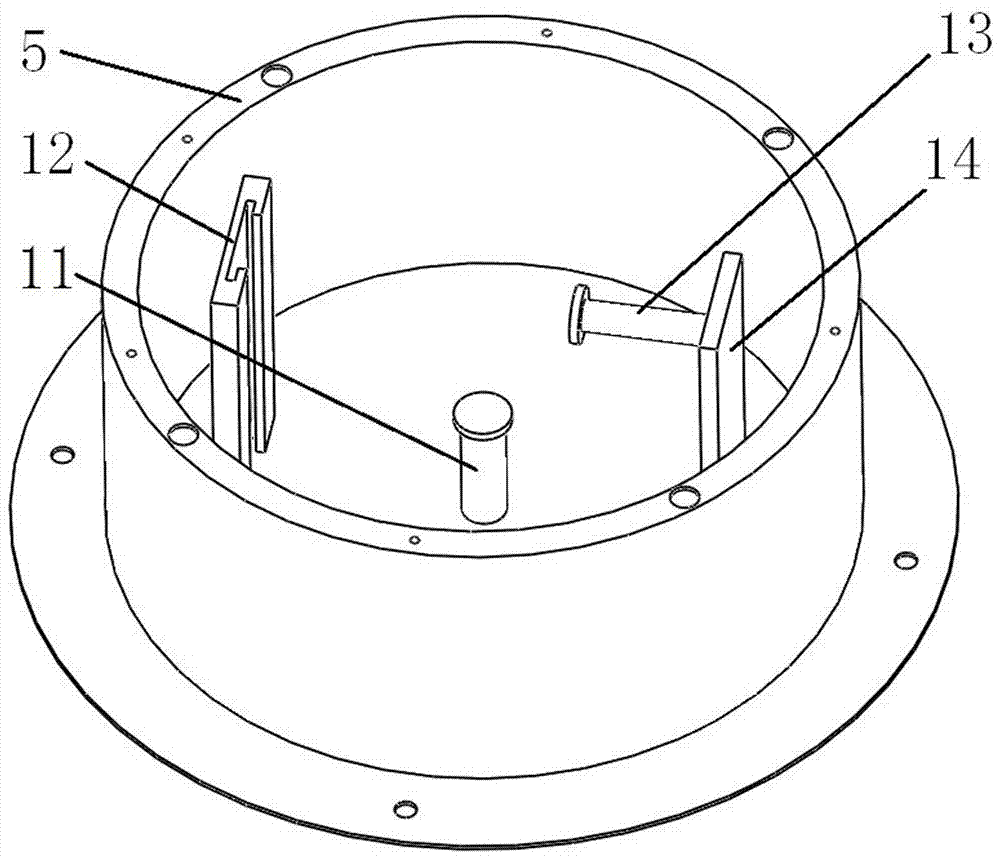

[0025] The vibration generating mechanism includes a support 5, a longitudinal magnetic induction mechanism arranged at the center of the bottom of the support 5, a transverse magnetic induction mechanism arranged on one side of the support 5, and a magnetic induction moving mechanism arranged at the middle of the support 5. , the material of the support 5 is cast aluminum,

[0026] The longitudinal magnetic induction mechanism includes an iron core I11 arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com