Working method for safe man-robot cooperation assembly robot

A technology of man-machine collaboration and working method, applied in the direction of manipulators, metal processing, manufacturing tools, etc., can solve problems such as time-consuming, poor work stability, complicated programming, etc., to achieve improved work stability, improved work efficiency, simple and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

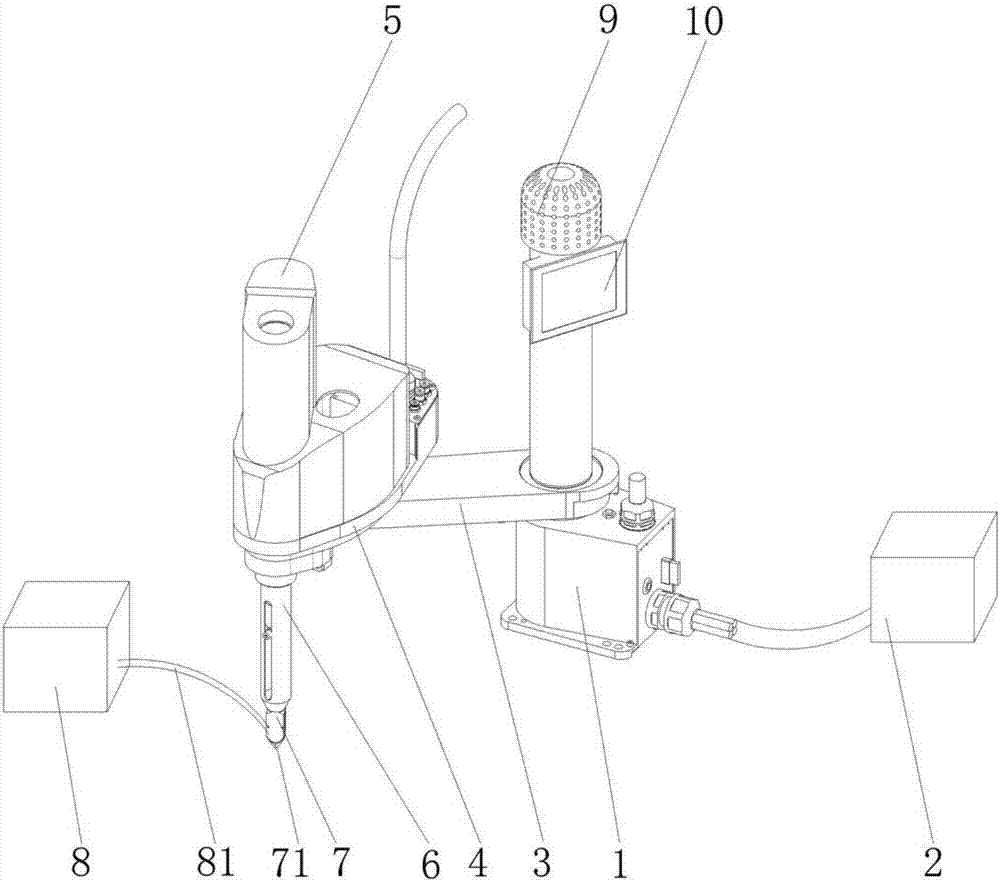

[0028] Such as figure 1 As shown, a working method of a safe human-machine collaborative assembly robot in this embodiment, the specific working steps are as follows:

[0029] (1) Start the power switch. First, the staff sets the working parameters and instructions through the controller 2 and the touch screen 10. The first articulated arm 3 and the second articulated arm 4 start to rotate in the horizontal direction driven by the AC torque motor adjust;

[0030] (2) Driven by the electric screwdriver 5, the screw starts to adjust up and down, and at the same time, the vacuum nozzle 71 starts to suck air, and the screw is sucked into the vacuum nozzle 71 by the feeder 8 through the feeding pipe 81 and the locking claw head 7 Middle position;

[0031] (3) When the screw moves to the corresponding screw hole, the screw rotates and presses down under the drive of the hollow shaft motor, and the screw is continuously screwed into the hole under the drive of the screw until the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com