Formed noise-reducing partitions with precise measurements

A technology of precision measurement and separation device, applied in the direction of manufacturing auxiliary devices, additive processing, etc., can solve the problem of inability to isolate the three-dimensional molding process, and achieve the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

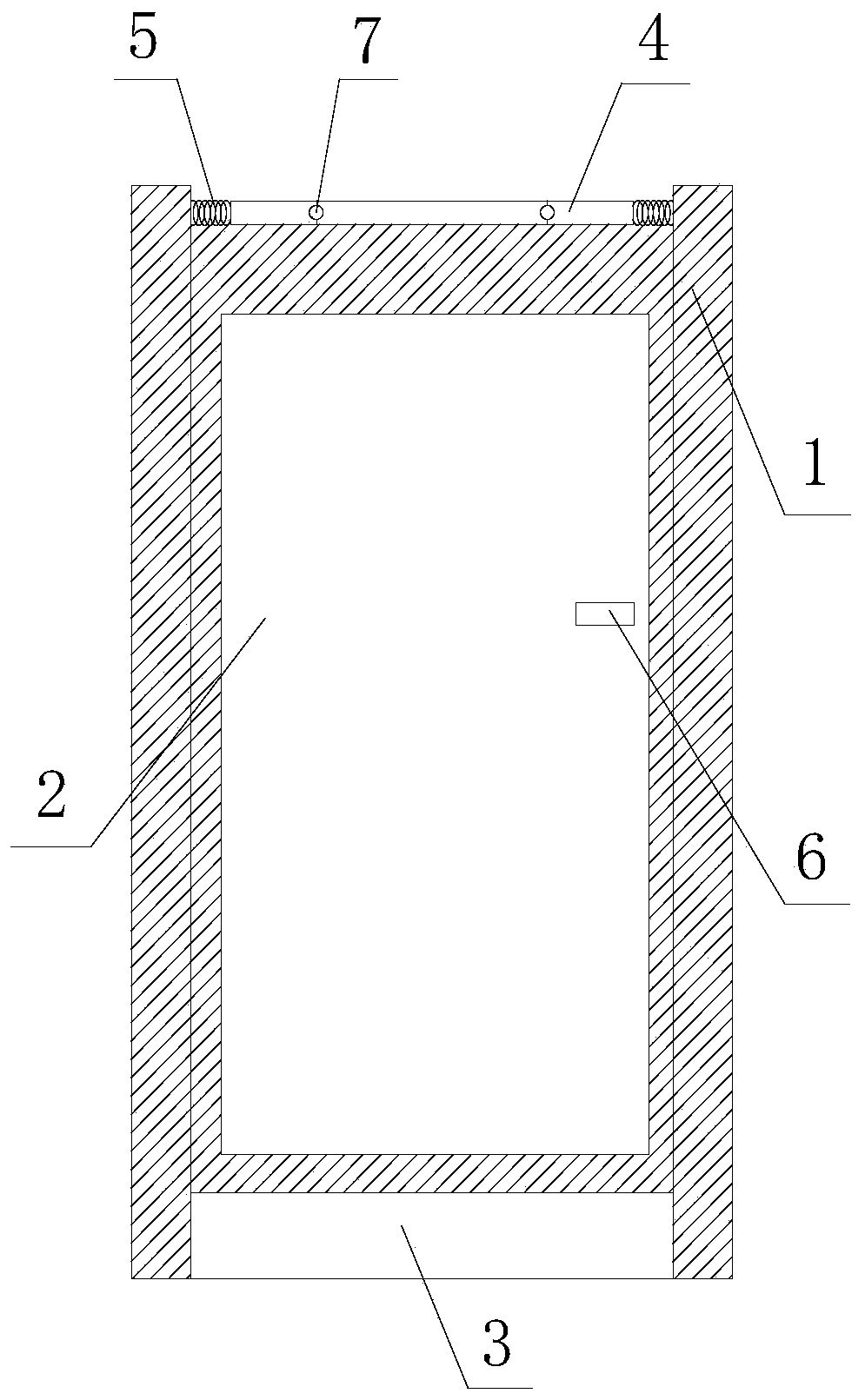

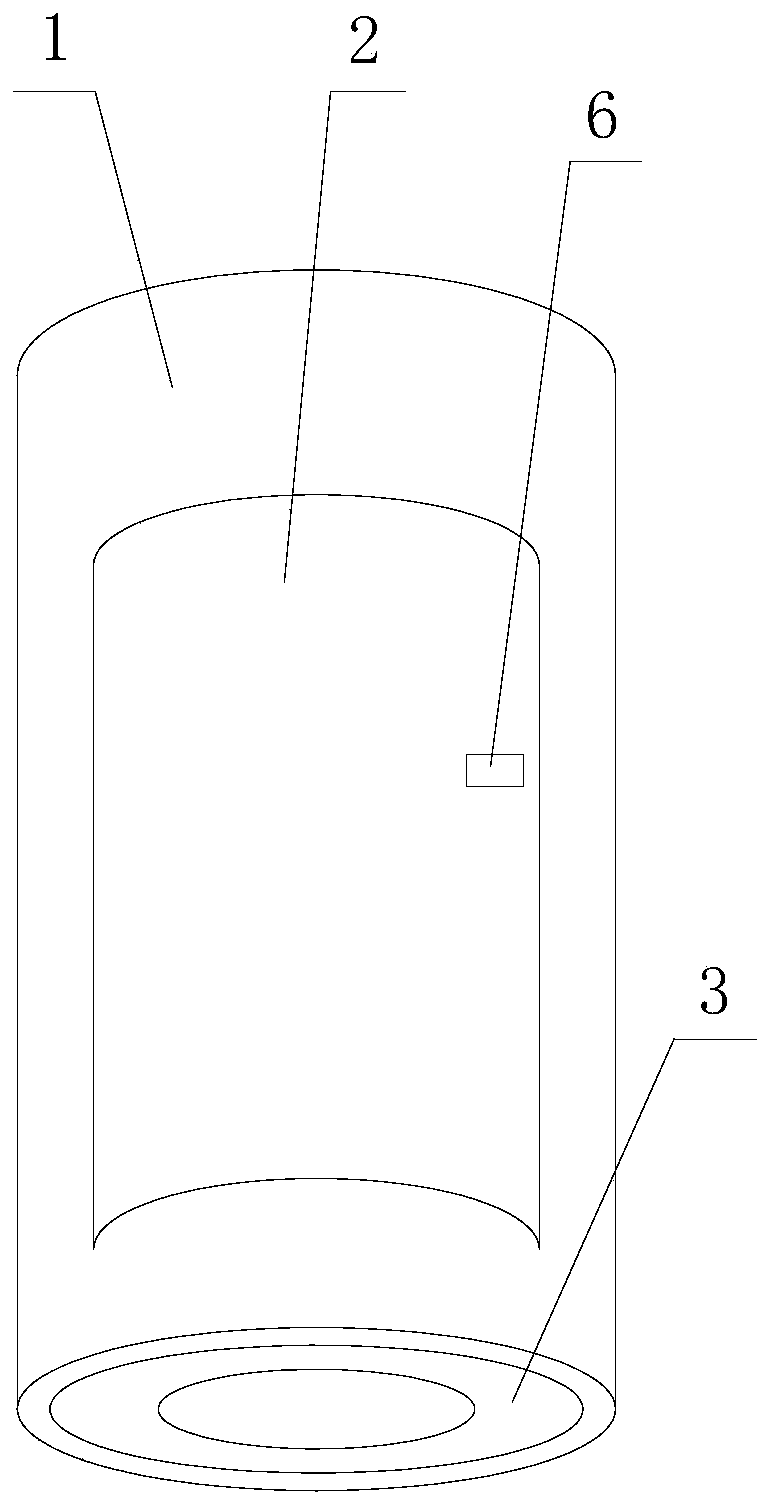

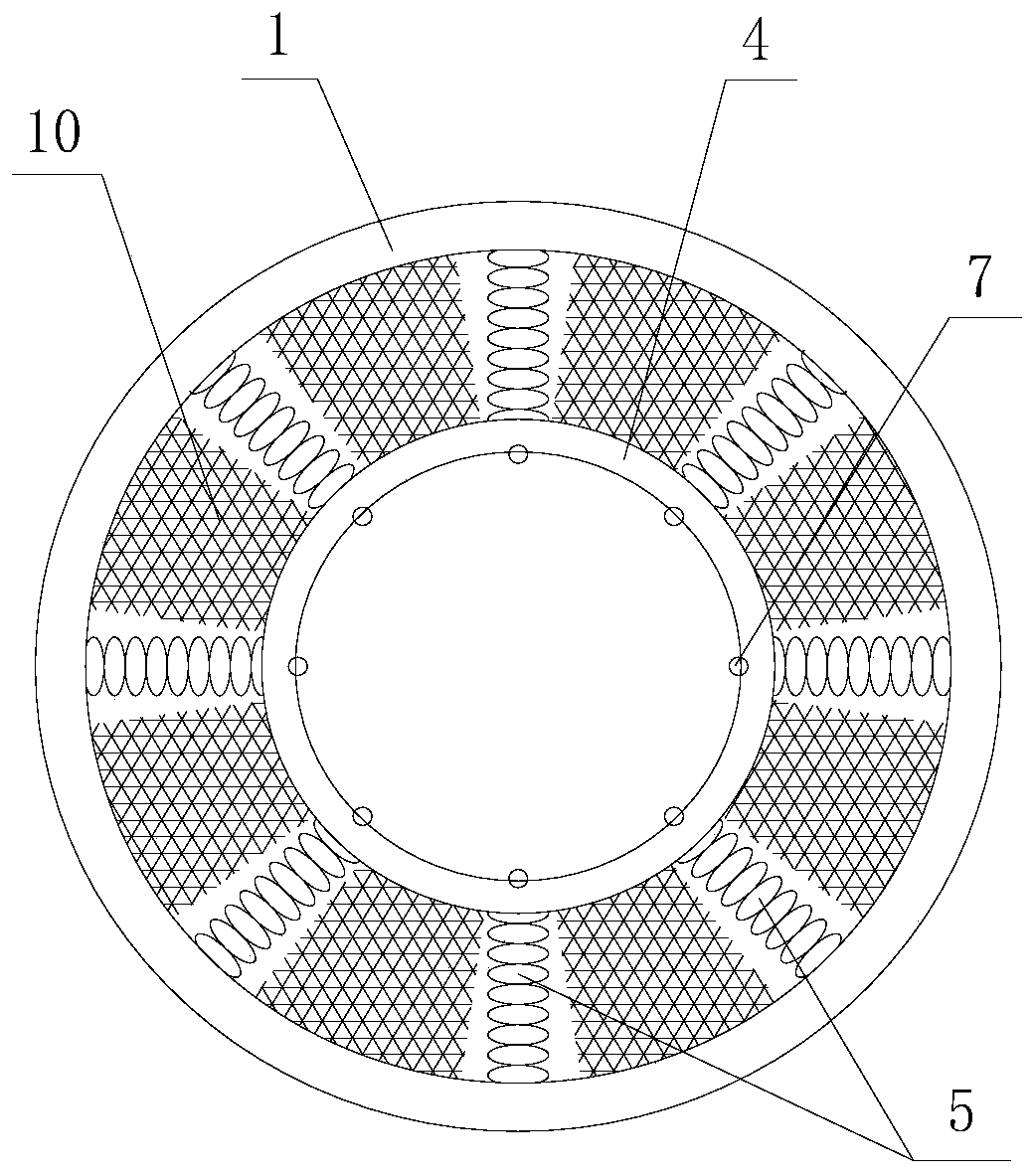

[0027] Such as Figure 1 to Figure 4The molded noise-reducing separation device matched with precise measurement as shown includes a cylindrical cylinder body 1 with upper and lower openings, a door opening is opened on the side of the cylinder body 1, and a door panel 2 is hinged at the door opening; the lower open end of the cylinder body 1 is fixedly connected to The hoop 3, the upper open end of the cylinder 1 is provided with a rubber ring 4, the hoop 3 and the rubber ring 4 are coaxial with the cylinder 1, and the outer side of the rubber ring 4 and the inner wall of the cylinder 1 The space is connected by eight evenly distributed springs 5, the axes of the eight springs 5 are coplanar, and the axis of each spring 5 is perpendicular to the axis of the cylinder body 1, and a sponge 10 is laid between two adjacent springs 5, so One end of the sponge 10 is fixed on the inner wall of the cylinder 1, and the other end is fixed on the outside of the rubber ring 4; the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com