Metal abrasive dust briquetting method

A wear debris and metal technology, applied in the field of metal wear debris briquetting, can solve the problems of unsatisfactory separation effect, high wear debris temperature, easy occurrence of spontaneous combustion, etc. Easy to squeeze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

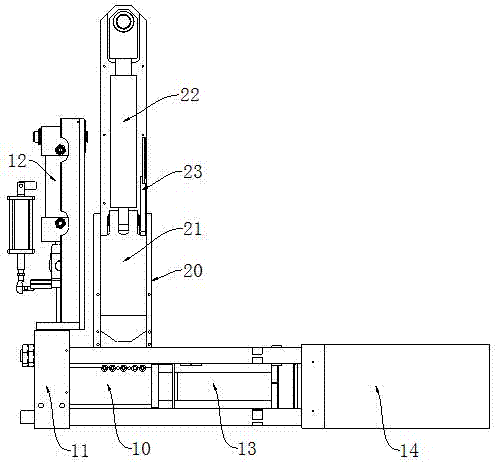

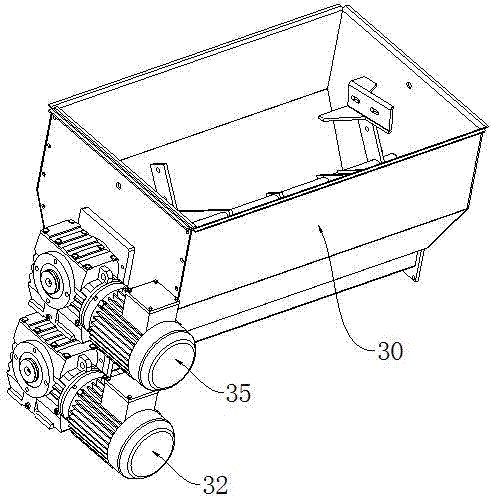

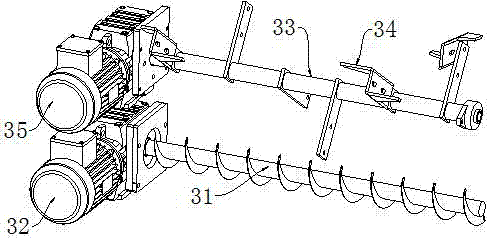

[0037] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0038] The technical scheme of concrete implementation of the present invention is:

[0039] The metal grinding dust processed by the present invention is the waste produced by various machine tools using grinding wheels as cutting tools to process metal materials. The grinding dust contains metal particles of the processed material, abrasive grains, binders used to bond abrasive grains, and a large amount of cooling liquid.

[0040] The morphology of metal particles in grinding debris mainly includes the following categories:

[0041] A. Curly strip-shaped metal shavings, with a width and thickness of about 20 microns and a length of 50-140 microns;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com