A test device and test method for deep plating ability of through hole

A test device and deep plating technology, applied in electrolytic components, electrolytic process, etc., can solve problems such as failure to meet through-hole deep plating capability verification, poor deep plating sample effect, etc., and achieve the effect of shortening production time and uniform and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

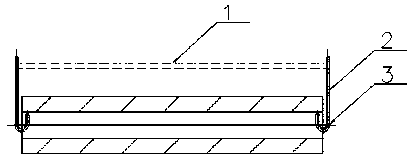

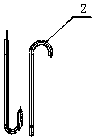

[0027] A test device for deep plating ability of through holes, consisting of figure 1 and figure 2 As shown, it includes a cathode conductive rod 1, both ends of the cathode conductive rod 1 are connected to a conductive hook 2, and the bottom of the conductive hook 2 is connected to a wire 3.

[0028] The wire 3 is a copper wire of Ф0.07-0.09;

[0029] The wire 3 is a Φ0.08 copper wire.

[0030] A method for testing with the aforementioned through-hole deep plating ability test device, specifically comprising the following steps:

[0031] (1) Prepare 1L of nickel plating solution and place it in the Hull cell, adjust the pH to 4.2-4.8, and the temperature is 50-55°C; the content of the nickel plating solution is 280g / L of nickel sulfate, 75g / L of nickel chloride and Boric acid 40g / L;

[0032] (2) Add additives that need to be tested or verified to improve deep plating ability; the content of additives is glycine 6ml / L, sodium butynyl sulfonate 1.5ml / L, sodium propynyl a...

Embodiment 2

[0040] A test device for deep plating ability of through holes, consisting of figure 1 and figure 2 As shown, it includes a cathode conductive rod 1, both ends of the cathode conductive rod 1 are connected to a conductive hook 2, and the bottom of the conductive hook 2 is connected to a wire 3.

[0041] The wire 3 is a copper wire of Ф0.07-0.09;

[0042] The wire 3 is a Φ0.08 copper wire.

[0043] A method for testing with the aforementioned through-hole deep plating ability test device, specifically comprising the following steps:

[0044] (1) Prepare 1L of nickel plating solution and place it in the Hull cell, adjust the pH to 4.2-4.8, and the temperature is 50-55°C; the content of the nickel plating solution is 320g / L of nickel sulfate, 90g / L of nickel chloride and Boric acid 50g / L;

[0045] (2) Add additives that need to be tested or verified to improve the deep plating ability; the content of the additives is 8ml / L of aminoacetic acid, 2ml / L of sodium butynyl sulfona...

Embodiment 3

[0053] A test device for deep plating ability of through holes, consisting of figure 1 and figure 2 As shown, it includes a cathode conductive rod 1, both ends of the cathode conductive rod 1 are connected to a conductive hook 2, and the bottom of the conductive hook 2 is connected to a wire 3.

[0054] The wire 3 is a copper wire of Ф0.07-0.09;

[0055] The wire 3 is a Φ0.08 copper wire.

[0056] A method for testing with the aforementioned through-hole deep plating ability test device, specifically comprising the following steps:

[0057] (1) Prepare 1L of nickel plating solution and place it in the Hull cell, adjust the pH to 4.2-4.8, and the temperature is 50-55°C; the content of the nickel plating solution is 220g / L of nickel sulfate, 60g / L of nickel chloride and Boric acid 30g / L;

[0058] (2) Add additives that need to be tested or verified to improve the deep-plating ability; the content of the additives is 4ml / L of aminoacetic acid, 1ml / L of sodium butynyl sulfona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com